Luton Box Van Body & Panels Manufacturer

The Luton Truck is a new van. It offers more cargo space behind the roof than a regular enclosed van. The large space allows for increased transportation efficiency.

Composite Box delivers a lightweight option. It uses fiberglass foam panels for Luton trucks. Core uses PET, PVC, and other high-density rigid foams. It has the advantages of light weight, high strength, and durability. Because of the reduced weight, it can be driven faster on the road. It also has a longer service life. It meets the needs of urban transport, cargo transport, and moving. It reduces cost and improves efficiency.

Features of the Luton Van

Composite Box’s Luton vans use FRP foam panels for the outside. The core is made of PET foam or PP honeycomb panels. They can greatly reduce the overall weight, which can improve driving speed, fuel savings, and other advantages. Below are the advantages of Luton vans:

Lightweight design

Composite Box uses new thermoset materials to design Luton vans. These materials can cut mass by over 50% compared to traditional options like sandwich panels, aluminum, and steel. Fuel efficiency can be greatly improved. Busy city roads and many traffic lights offer flexibility. This reduces start-up time, makes driving easier, and ensures goods arrive on time. Plus, they keep the driver comfortable.

High protection performance

The outer skin adopts fiberglass as the skin; the panel can resist impact strength as high as 500J/m, and the wear-resistant coefficient is over 0.8. Roadside railings and trees help keep things safe. They can withstand collisions and scrapes. In tough conditions, they offer lasting protection for both the vehicle and its cargo.

Durability and corrosion resistance

That’s nothing compared to Composite Box’s Luton boxcars. We are confident in the fiberglass skin for several reasons:

- It won’t oxidize.

- It has a gelcoat finish that protects against corrosion and weather.

- It provides insulation to keep the cargo safe and boost longevity.

Get Free Quote of Luton Box Van Body

product Catalog

contact us

What makes FRP sandwich panels better than traditional materials?

Luton trucks use fiberglass sandwich panels. These panels boost load capacity, cut maintenance costs, and are recyclable. A perfect alternative to traditional aluminum and wood panels.

Increased load capacity

Weights as low as 460 kg optimize heavy-duty transport.

Sustainable materials

PP honeycomb panels cut emissions. Recycling PET foam helps the environment.

Fuel Efficiency

A lighter body reduces fuel consumption and saves long-distance transportation costs.

Low-maintenance cost

Corrosion-resistant panels are easy to maintain, reducing repair expenses.

Why choose Luton Trucks from Composite Box?

Composite Box is the leading manufacturer of Luton trucks in China. We have 30 years of truck design experience. We build strong customer relationships in the US, Australia, Canada, and Europe. Our happiest moments come when customers trust us. We keep investing our profits in research and development. This helps us create better lightweight truck solutions. We also share our knowledge with trucking and logistics companies in the community.

We serve our global customers and have an international team with 15 languages.

Repair/replacement service available

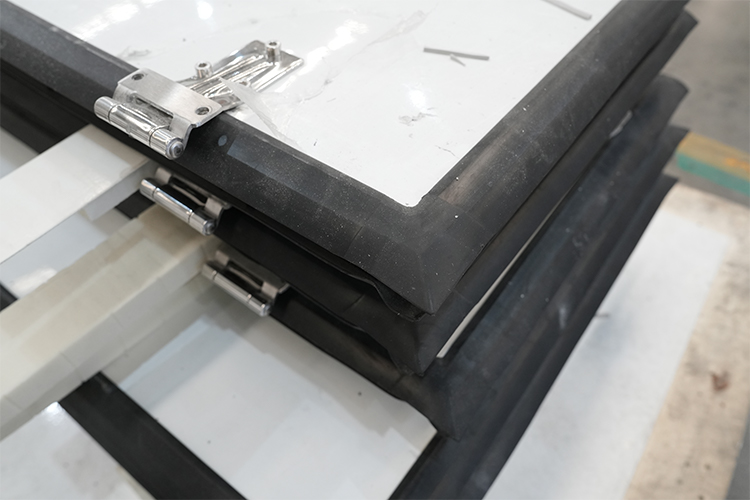

Composite Box is a leading manufacturer of Luton vans in China. In addition to providing total Luton van solutions to our global customers, we also offer replacement side panels and side/rear door kits for Luton vans. This is a 100% customized modular design. Replacement is extremely easy and can be done quickly with basic tools.

Luton Van Side Panel Replacement: FRP (fiberglass reinforced plastic) sandwich foam panels. Lightweight and superior impact resistance. Whether it’s due to bumps, scratches or long-term deterioration. We offer factory-grade replacement panels that are precisely sized to fit. And to match your installation.

Luton van Side and Rear Door Kit Replacement: You can replace your old doors with new ones. We offer single door, double door, and automatic lift tailgate options that are compatible with your luton truck. Our door kits have better sealing performance and speed up loading and unloading to improve logistics efficiency. And they are excellent in dustproof and waterproof.

Quick Assembly CKD Kits for Safety

Composite Box offers both CKD and SKD delivery options, enabling assembly in as little as one hour without welding. This accelerates installation while maintaining quality and reducing costs.

Only requires an electric drill, socket wrench, level, tape measure, and silicone caulking gun. Below are sample installation steps:

- Secure the chassis beams: Align the pre-drilled aluminum alloy bottom beams with the chassis and secure with M10 bolts (torque 45N·m).

- Install side wall panels: Insert FRP panels into the bottom beam slots and secure them to the crossbeam with self-tapping screws at the top (one screw every 30cm).

- Assemble front wall + roof: Connect the front wall to the side walls using 45° aluminum connectors. Secure the roof with rivets + sealant.

- Install rear door system: Mount hinges → Install door lock → Apply weatherstripping (IP65 waterproof rating).

- Add optional accessories: E-Track rails, tail lift (500-1500kg capacity), LED light bar.

Exceptional Design Capabilities

Our Luton box van body supports multiple chassis platforms, including Ford, Mercedes, VW, Iveco, Peugeot, Renault, and more.

Customization options

We offer customization options for length and height, as well as multi-temperature zone designs with multiple temperature control zones. Over 20 customization options are available.

parameters

| Parameter | Details |

|---|---|

| Body Length | 4 m – 11.8 m (Customizable) |

| Body Height | 1.8 m – 3 m |

| Panel Thickness | 10 mm – 80 mm |

| Skin Material | FRP (Fiberglass), Aluminum Alloy |

| Core Material | PET Foam, PP Honeycomb, Plywood |

| Surface Finish | Glossy, Matte, Gel-Coated (Anti-UV) |

| Weight | 460 kg – 813 kg (Body), 40%-60% Lighter than Aluminum |

| Payload Capacity | 750 kg – 2000 kg |

| Water Absorption | <1.5% (Foam Core) |

| Compressive Strength | 200 kPa (Core-Dependent) |

| Assembly Type | CKD (Completely Knocked Down), SKD (Semi-Knocked Down) |

Application of Luton box vans

- Logistics and cargo transport

- Furniture moving services

- Dry goods delivery

- Industrial equipment haulage

- Retail goods distribution

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.