XPS core Sandwich panels manufacturer in china

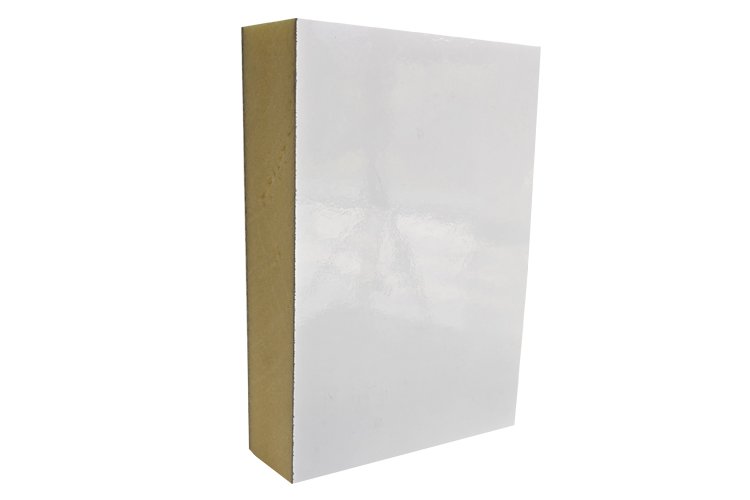

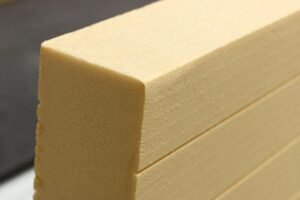

XPS foam sandwich panels are popular insulation materials called ‘XPS insulation boards’. Good thermal and acoustic insulation is frequently used in refrigerated trucks and RVs. It has an XPS (closed cell extruded polystyrene) core. The outside is bonded with FRP, plywood, or CFRT. The XPS foam is a great thermal insulator. It does not absorb water, so it has a long service life. The skin makes XPS panels perform better. The FRP skin can replace traditional materials, like 알루미늄 and steel, to make them stronger. It’s the best choice for 냉장 트럭 and RV panels.

We are the most professional XPS sandwich panel manufacturer in China. We offer OEM production with customized sizes and skins, CNC machining services.

제품 설명:

XPS sandwich panels are high-performance and very durable, and they offer many advantages. The best advantage is its excellent thermal and sound insulation.

- Good thermal insulation and heat preservation performance.

- High strength: bonded skin to form a high-strength sandwich panel

- Durable: not easy to corrode or age

- Strong: not easy to deform and compress

- Insulation prevents air from entering and exiting.

- Non-absorbent: a closed-cell structure prevents water absorption.

- Chemically stable and designed for a long service life.

사용자 지정:

- Surface skin: FRP skin, CFRT, aluminium sheet, plywood, etc.

- Size: length ≤12m, width ≤3.2m, thickness: 20mm~120mm.

- Density: 25~45kg/m³

- Colour customization: yellow, green, blue.

- Skin colour: according to the type of masking

- Compressive strength: tuning density and proportion of foaming agent

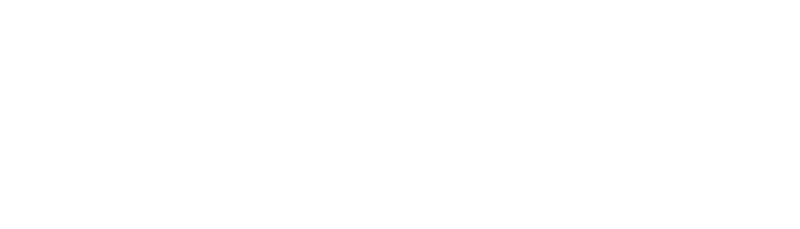

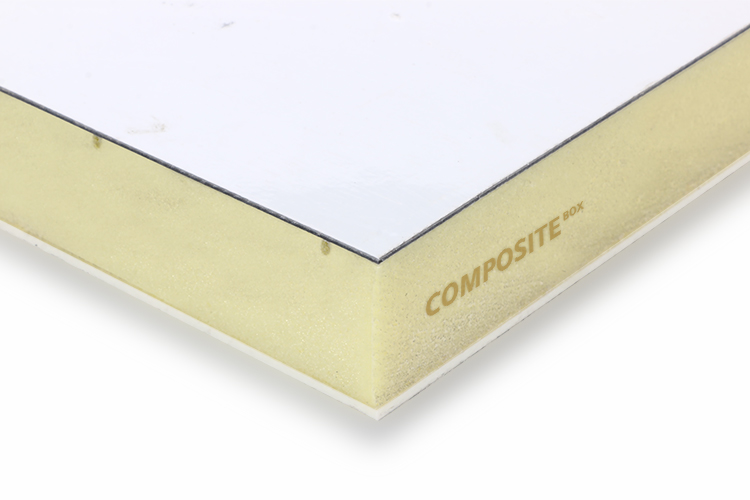

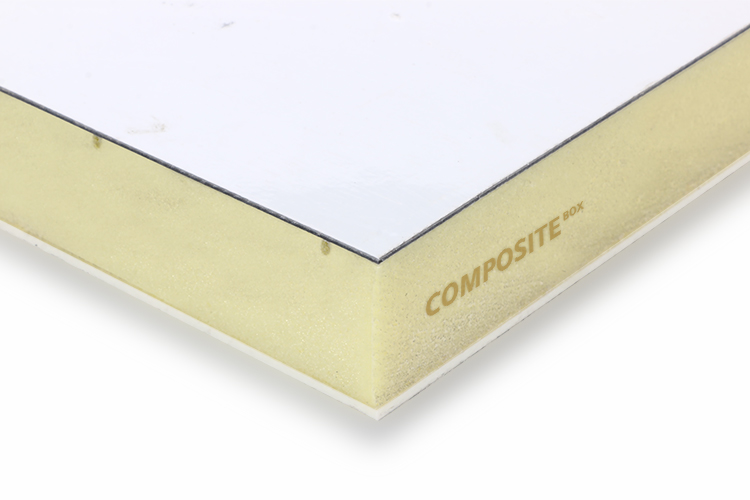

Product Structure:

XPS 폼 보드

XPS foam board is also called extruded polystyrene board, it is a kind of rigid closed-cell foam, which has obvious difference with expanded polystyrene, it has less than 1% moisture absorption. Low thermal conductivity. Good impact resistance.

Fiberglass Reinforced Plate

Fiberglass reinforced plate is made by combining glass fibers and resin matrix. It is suitable for the manufacture of fiberglass XPS foam board, which is a high-performance composite material.

사양:

| 매개변수 | 설명 |

| 두께 | 10~140 mm |

| 치수 | Max 360 x 1200 cm |

| 핵심 재료 | XPS 폼 |

| 스킨 재질 | FRP (0.7~5.0 mm), Continuous Glass Fiber, Plywood |

| 코어 밀도 | 28~55 kg/m³ |

| 피부색 | RAL Series |

XPS physical properties:

| 매개변수 | 설명 |

| 밀도 | 33-50 kg/m³ |

| 압축 강도 | 500-700 kPa |

| 열 전도성 | 0.028-0.035 W/(m·K) |

| R-Value | ~5 per inch |

| 수분 흡수 | <1% (closed-cell structure) |

| Fire Rating | B1/B2 (China standard) |

| 작동 온도 | -50°C to 75°C |

컴포지트 박스

application:

XPS foam panels are very versatile. They are mainly used in refrigerated lorry bodies and trailers, but also in caravans and mobile buildings.

관련 제품

왜 우리를 선택해야 할까요?

고객 만족

고객 경험을 중심으로 고품질의 제품과 서버를 고집합니다.

품질 보증

고객에게 신뢰할 수 있는 품질 보증을 제공하기 위해 모든 생산 공정을 엄격하게 관리합니다.

고급 생산 라인

세계 최고의 생산 라인은 제품의 정밀도와 효율성을 보장합니다.

사용자 지정

100% 커스터마이징을 제공하므로 주문이 더 쉬워집니다.