Fiberglass Reinforced Plywood Sandwich Panels

Fiberglass reinforced plywood panels are a high-strength, impact-resistant material that consists of 2 pieces of FRP sheets and plywood and is formed into FRP plywood panels. They can withstand great pressure and have the advantages of both FRP and plywood and are widely used in various applications.We work as a professional supplier for you.

We support customized production, OEM/ODM, and finished products such as trailers, carriages, and motor homes.

제품 설명:

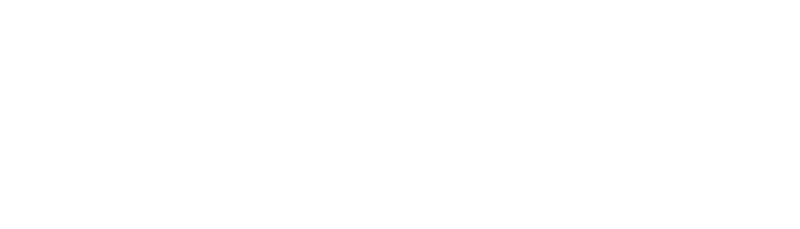

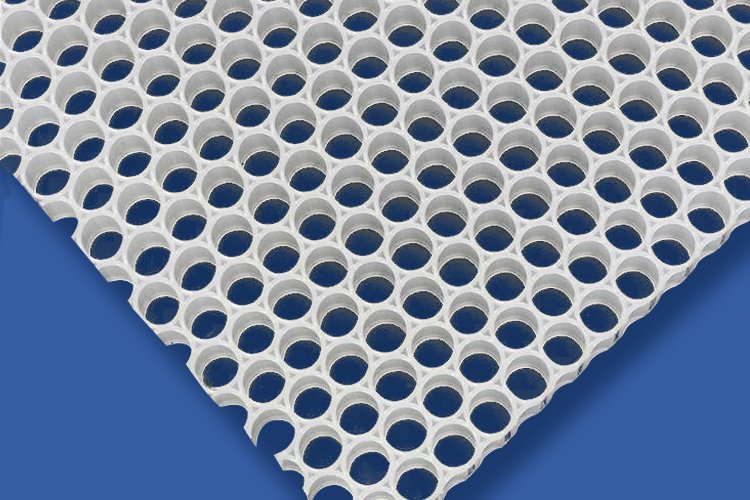

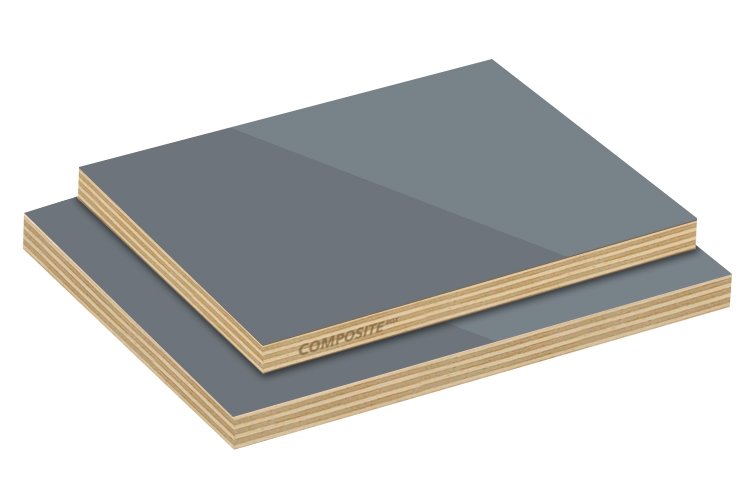

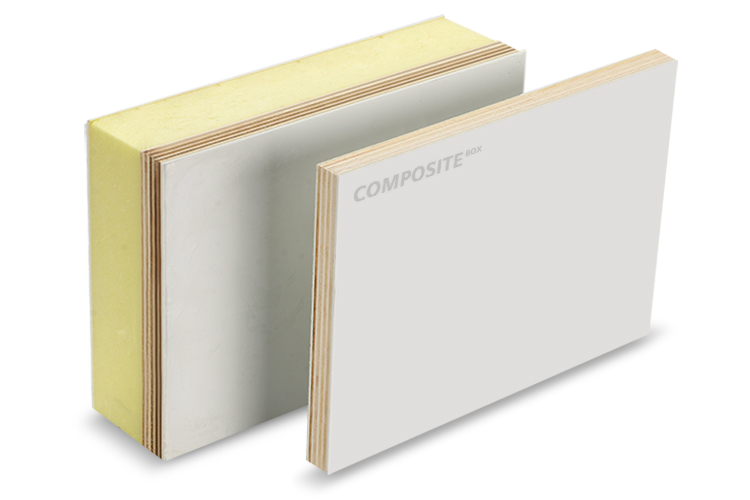

Fiberglass reinforced plywood panel structure: 2 layers of fiberglass sheets as exterior, core of plywood, formed by laminating 7 to 13 layers of thin wood.

Composite-box has been producing fiberglass reinforced plywood panels for over 20 years. Although plywood panels are a high-strength material, they are not waterproof, are prone to rot, and have many disadvantages. Nowadays, with FRP skin, they are able to be waterproof, scratch-resistant, rot-resistant, and UV-resistant, among other benefits. So, covering the the FRP sheet with plywood is a better choice.

Composite-box has been producing fiberglass reinforced plywood panels for over 20 years. Although plywood panels are a high-strength material, they are not waterproof, are prone to rot, and have many disadvantages. Nowadays, with FRP skin, they are able to be waterproof, scratch-resistant, rot-resistant, and UV-resistant, among other benefits. Options like stainless steel faced plywood also enhance durability for specific applications. So, covering the FRP sheet with plywood is a better choice.

customization

We support product customisation and can produce different thicknesses on request, from 9mm to 22mm, lengths up to 12m and widths up to 3.2m. Customized FRP patterns and colours are available, as well as different skin finishes, and non-woven fabrics can be added to enhance adhesion. Sourcing fiberglass reinforced plywood, composite box is the best choice.

Product Advantages

애플리케이션

Fiberglass Roofing and Partitions on Plywood

Used for roofing, partitions and wall panels. Thickness in 10~50mm, waterproof and UV resistant, suitable for mobile homes, container homes, providing long lasting protection.

plywood fiberglass aquarium

Waterproof and pressure resistant, can be made into a large aquarium. The water body can reach 500L, durable for more than 20 years.

Fiberglass Plywood Cattle Shed

Thickness 10~30, waterproof and moisture-proof, suitable for wet environment, protect livestock, corrosion-resistant, not easy to be damaged by cattle.

Structure of fiberglass plywood

합판

plywood is multiple layers of different thin wood slices laminated with adhesives to achieve high strength properties and is highly resistant to compression, maximizing the use of wood.

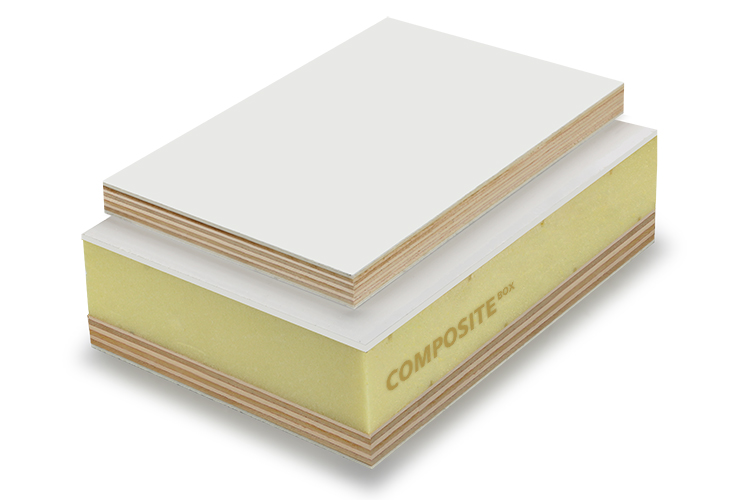

FRP Fiberglass sheet

PET(폴리에틸렌 테레프탈레이트)는 화학적으로 안정적이고, 전 세계적으로 친환경 재활용 소재로 인정받고 있으며, 폐쇄형 셀 구조로 구성되어 방수 및 방습 기능이 있어 다양한 용도로 활용하기에 이상적인 소재입니다.

컴포지트 박스

Application of fiberglass reinforced polywood panel :

FRP sandwich panels can be used mainly in scenarios that need high strength.

제품 매개변수

| 속성 | Specification/Value |

|---|---|

| 피부 두께 | 1.5mm |

| 코어 두께 | 11 mm |

| 면적 밀도 | 1 Kg/m² |

| 굴곡 강도 | 36.966MPa(최대 하중: 2770.659N, 샘플 크기: 300x100x14mm) |

| 압축 강도 | 13.053 MPa(최대 하중: 2770.659N, 샘플 크기: 60x60x14mm) |

| 스킨 재질 | FRP(유리섬유 강화 플라스틱) 또는 CFRT(연속 섬유 강화 열가소성 플라스틱) |

| 핵심 재료 | 합판(포플러, 소나무, 유칼립투스, 오크 등) |

| 표면 처리 | 젤코트 FRP(두께: 0.7-5.0mm) |

| 복합 방법 | 친환경 접착제 |

| 두께 범위 | 5-50mm |

| 길이 범위 | ≤12000 mm |

| 너비 범위 | ≤3200mm |

FRP 스킨 합판과 순수 합판의 성능 비교

| 항목 | 힘 | 방수 성능 | 내화성 | 표면 매끄러움 | 예상 수명 | 내습성 | 단열 |

|---|---|---|---|---|---|---|---|

| FRP 스킨 합판 | 우수 | 우수 | 평균 | Smooth | Long | Good | 우수 |

| 순수 합판 | 평균 | Poor | Poor | Rough | 짧은 | Poor | 평균 |

왜 우리를 선택해야 할까요?

고객 만족

고객 경험을 중심으로 고품질의 제품과 서버를 고집합니다.

품질 보증

고객에게 신뢰할 수 있는 품질 보증을 제공하기 위해 모든 생산 공정을 엄격하게 관리합니다.

고급 생산 라인

세계 최고의 생산 라인은 제품의 정밀도와 효율성을 보장합니다.

사용자 지정

100% 커스터마이징을 제공하므로 주문이 더 쉬워집니다.