Duraplate Truck Body Solutions CKD/SKD

Composite Box offers Duraplate truck body solutions. This solution utilizes recycled materials to reduce environmental pollution.

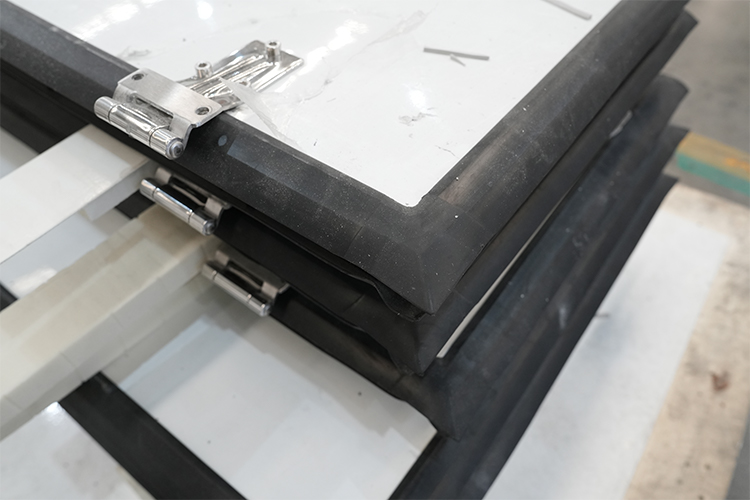

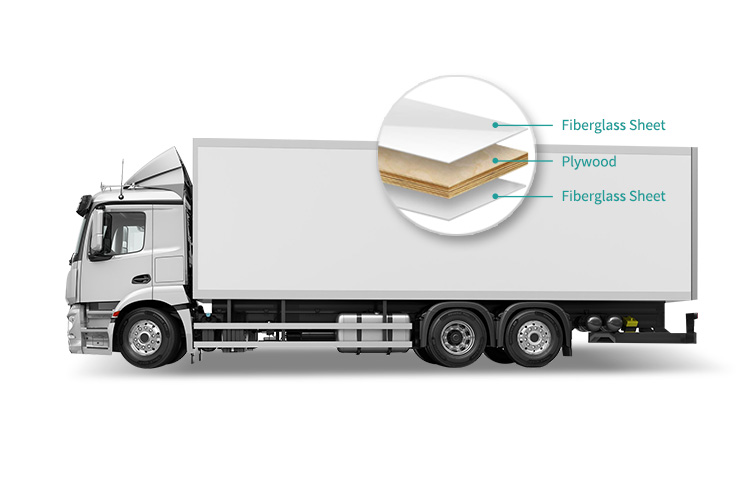

Duraplate features a high-density polyethylene core with a double-layer skin of high-strength steel or fiberglass, bonded through a high-pressure thermal composite process. Various composite materials and configurations are available.

特徴

Composite Box offers an eco-friendly Duraplate composite truck body solution. It is the ideal choice for modern logistics. Utilizing high-density polyethylene (HDPE) as the core, it is thermally bonded with high-strength galvanized steel or fiberglass skins. This process achieves durability, lightweight construction, a smooth surface, and excellent impact resistance. Capable of operating in diverse climates, it delivers superior moisture resistance and corrosion protection.

We deliver via SKD/CKD kits for simple, reliable modular assembly. Perfect for dry van, trailer, and semi-trailer body manufacturing. We provide 3D design drawings and fully customized solutions. Contact our experts to customize Duraplate box bodies in any size or configuration.

Get Free Quote of Duraplate Truck Body

What Duraplate box body solutions are available?

HDPE Galvanized Steel Solution

Constructed using a high-density polyethylene core laminated under high pressure with dual layers of high-strength galvanized steel plates.

Delivers superior lightweight and corrosion-resistant properties. Compared to all-steel construction, it achieves a 30% weight reduction while maintaining corrosion resistance. The HDPE core provides vapor barrier functionality. Ideal for general cargo transport and high-load trucks in less-than-truckload express services.

Duraplate Fiberglass Solution

Featuring an HDPE core with a fiberglass skin, this offers an excellent composite structure.

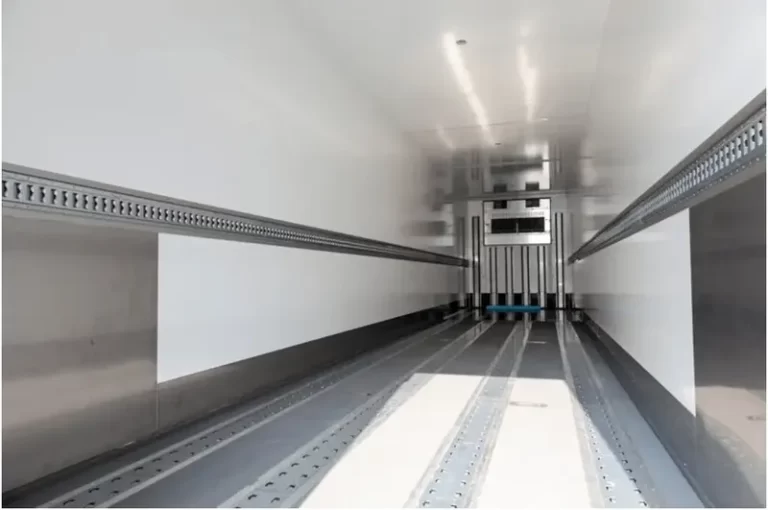

The corrosion-resistant fiberglass skin provides protection against corrosion and excellent impact resistance, making it particularly suitable for refrigerated and insulated vehicles.

HDPE Core Material with High Proportion of PCR

The HDPE core material utilizes a high proportion of PCR, promoting environmental sustainability. It contains a significant recycled content, helping fleets achieve carbon reduction goals and meet ESG requirements.

Suitable for companies with an eco-friendly brand image. Ideal for scenarios or businesses with relatively lower strength requirements.

Duraplate Features

Weight Reduction & Fuel Efficiency: Compared to traditional steel bodies, the Duraplate solution achieves up to 30%-40% weight reduction, delivering long-term fuel cost savings of 5%-10% for fleets.

Durability Guarantee: Based on accelerated aging tests, Duraplate bodies are designed for over 15 years of service life under normal operating conditions, with a 10-year guarantee against corrosion perforation.

Structural Strength: The composite structure, formed through high-pressure thermal lamination, meets EN 12623 standards for impact resistance, effectively withstanding collisions during loading and unloading.

アプリケーション・シナリオ

With eco-friendly recycled materials and superior corrosion resistance, it can be widely applied in various scenarios:

- Dry cargo transport vehicles

- Refrigerated and insulated vehicles

- Express delivery and logistics vehicles

- Urban distribution vehicles

- Special-purpose engineering vehicles

当社を選ぶ理由

顧客満足度

顧客体験を中心とした高品質の製品とサーバーにこだわる

品質保証

私達は私達の顧客に信頼できる品質保証をもたらすためにあらゆる生産過程を厳しく制御します。

高度な生産ライン

世界トップレベルの生産ラインは、製品の精度と効率を保証する。

カスタマイズ

我々は100%のカスタマイズを提供し、注文の難易度を下げます。