HPL Sheet Manufacturer

HPL panels are high-pressure laminates. Leveraging China’s supply chain advantages, we can easily produce HPL panels in diverse styles that are cost-effective, durable, hygienic, and fire-resistant.

- Over 15 years of manufacturing experience

- Extensive Selection: We provide up to 200 decorative finish options

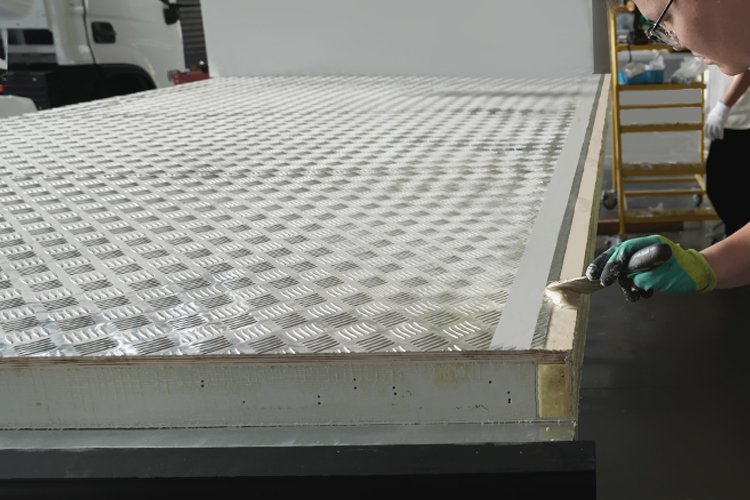

- Versatile Applications: Compatible with interior designs for trucks and RVs

HPL sheets

Composite Box’s HPL laminates have earned strong market trust through continuous product development and maintaining high flexibility. We offer an extensive selection of standard patterns and designs, along with a rich color palette. Options include natural wood tones, various wood stains, stone textures, and vibrant patterns, with custom colors also available.

Our products serve diverse applications across furniture, home interiors, refrigerated trucks, cargo bodies, RVs, construction, restaurants, hospitals, schools, ships, and both indoor/outdoor settings.

Below are selections from our product range:

6mm HPL sheets

6mm thick high-pressure laminate, tough and impact-resistant, ideal for furniture panels and wall cladding.

Wood-effect HPL Sheets

Realistic wood grain HPL, featuring natural oak and walnut patterns, warm and durable, the top choice for cabinetry and furniture.

Black HPL Sheets

Deep black/charcoal HPL, available in matte or gloss finishes, offering understated modernity with fingerprint-resistant and scratch-resistant properties.

Waterproof HPL Sheets

Highly water-resistant high-pressure laminate, moisture-proof and humidity-resistant, specifically designed for humid environments like bathrooms and kitchens.

White HPL Sheets

Pure white/snow white HPL, bright and clean, stain-resistant and easy to coordinate, commonly used for cabinetry, wall panels, and laboratories.

Marble-Pattern HPL Sheets

Marble-effect HPL with luxurious stone aesthetics, lightweight and easy to install, ideal for premium countertops and walls.

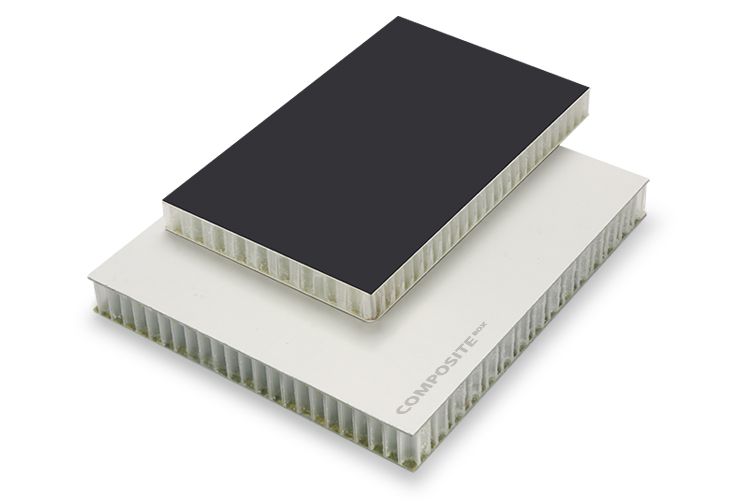

Solid Core HPL Sheets

Full-core solid HPL with dense, high-strength construction. Self-supporting, fire-resistant, and impact-resistant, perfect for partition doors.

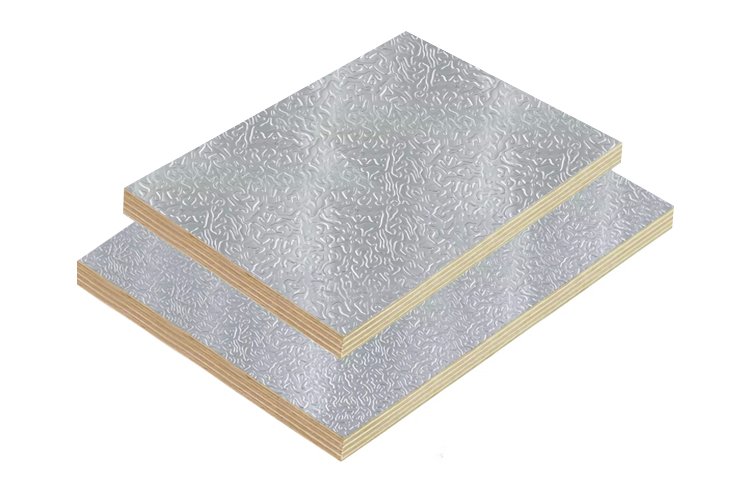

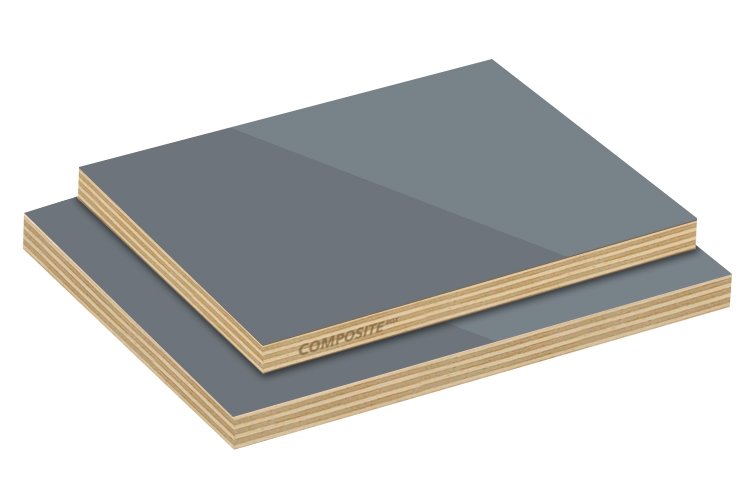

Plywood HPL Sheets

HPL laminated onto plywood substrate for enhanced strength and durability. The top choice for supporting and decorating furniture cabinets.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.

Production Process

HPL panels are manufactured using decorative paper impregnated with melamine resin (including a wear layer) and phenolic resin kraft paper as the base material. During manufacturing, the wear layer, decorative layer, and multiple layers of kraft paper are precisely laminated. A textured steel plate is then placed over the decorative layer. Subsequently, the entire assembly undergoes a single hot-pressing process at high temperature (approximately 150°C) and high pressure (>5MPa), firmly bonding all layers into a solid sheet. Finally, after cooling and trimming, the finished product features a distinct surface texture and exceptional wear resistance.

What colors of HPL sheets do you offer?

We provide wood grain, stone grain, metallic textures, and solid-color HPL sheets with diverse surface finishes. As a leading HPL composite manufacturer, we offer over 200 styles:

- Solid Colors: White, Snow White, Gray, Black, Deep Obsidian or Charcoal Black, Navy Blue, Burgundy, Orange, Yellow, and other RAL solid colors.

- Wood Grain Series: Walnut, Oak, Cherry, Maple, Gray Oak, Natural Wood, Smoked Wood, and other highly realistic natural wood finishes.

- Stone Series: Marble (White Carrara, Black Golden Flower), Concrete Gray, Limestone, Sandstone, and other modern industrial styles.

- Metal/Special Textures: Brushed Metal, Fabric Texture, Leather Grain, Concrete Finish, Matte/High-Gloss/Velvet, etc.

What HPL processing services do you offer?

HPL surfaces are smooth, scratch-resistant, stain-resistant, and easy to clean. Edges are precision-ground for safety and burr-free finish. Postforming technology enables seamless 180° curved wrapping, providing moisture resistance and hygienic coverage with no dead corners—ideal for kitchen countertops and laboratories.

- Available textures: Matte, velvet, glossy, fabric-like

- Professional edging: ABS/PVC/color-matched HPL for seamless aesthetics

- Post-forming: Integrated curved molding for durability and moisture resistance

- Supports CNC machining with diverse color and pattern options

HPL Sheet Applications

- Kitchen countertops

- Office desktops

- Laboratory countertops

- Cabinet doors

- Interior partitions

- Exterior wall cladding

- Store counters

- School furniture

- Hospital wall panels

- Bathroom vanities