GRP Coated Plywood Sandwich Panel

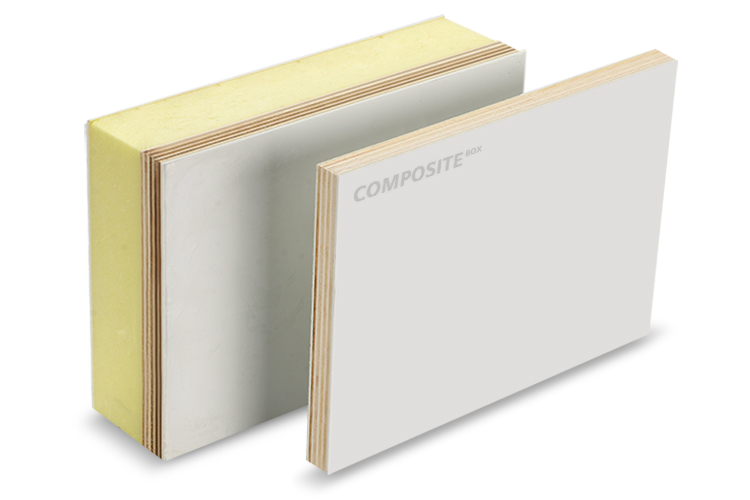

GRP plywood sandwich panels are high-performance composite materials. Made from GRP laminated with marine-grade plywood. Enhance the waterproof and moisture resistance of plywood to prevent rotting. They replace traditional steel and aluminum panels. Service life of up to 40 years. Reduces weight by more than 40% compared to traditional metal panels. They are used in the production of kitchen cabinets, furniture, camper trailers, and box trucks.

Features

Why use GRP-coated plywood panels?

GRP is a stabilized composite material. It has lightweight and high-performance benefits, and is water and moisture resistant. Marine-grade plywood makes better use of timber. It has several layers of thin wood glued together. Layers are cross-laminated at 90 degrees. GRP protects marine-grade plywood from moisture and corrosion. Enhances the impact and bending resistance of plywood. It protects the exterior from scratches and insulates from air. It makes the sandwich panel easier to maintain.

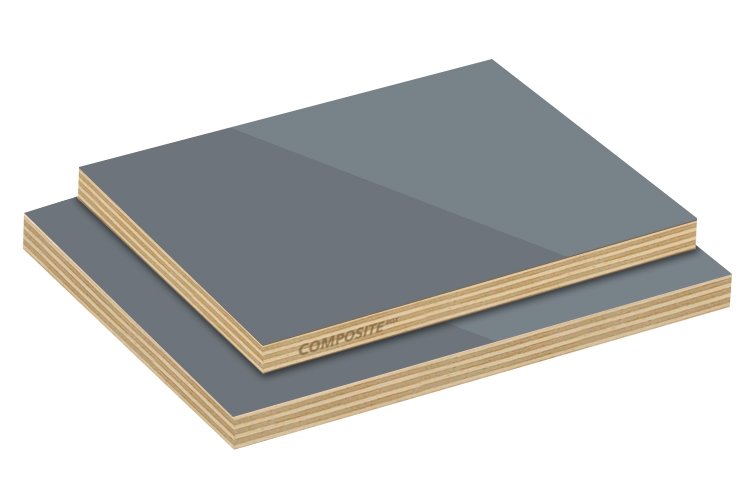

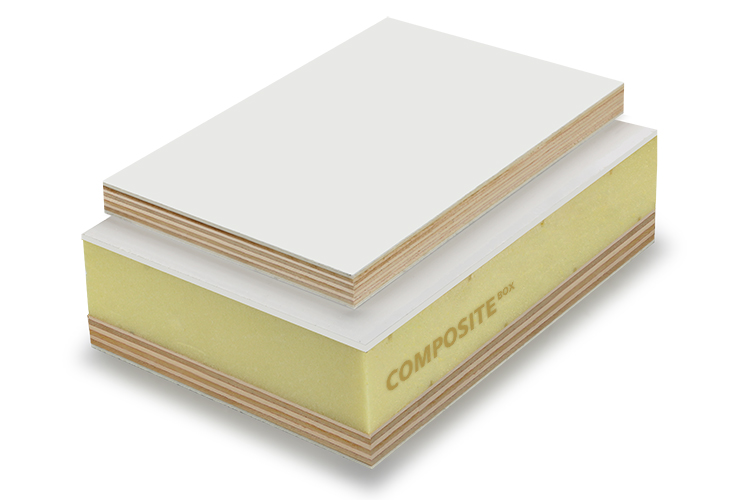

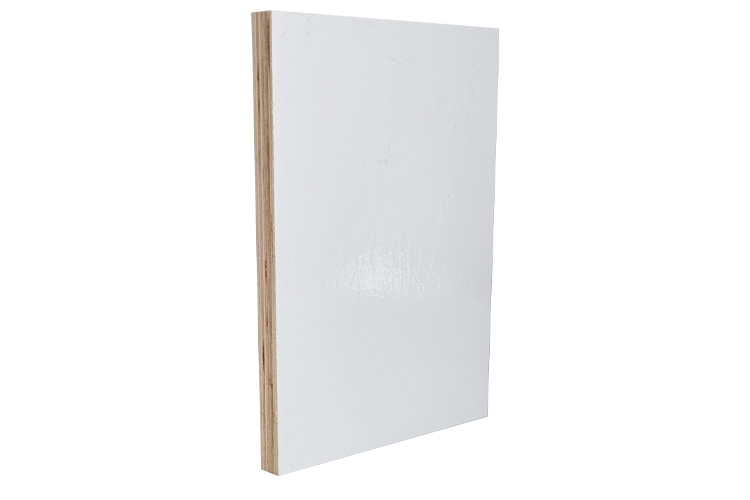

Our GRP plywood panels feature a monolithic composite construction for enhanced strength and structural integrity. This improves stability and impact resistance. We offer mainstream GRP plywood thicknesses including 18mm and 20mm.

Get Free Quote of GRP Coated Plywood Sandwich Panel

Customized Solutions:

Camping Trailer/RV Body GRP Plywood Solutions:

GRP plywood panels can be used in teardrop trailers, camping motorhomes, and off-road RVs. Compared to traditional aluminum alloy materials, they reduce weight by over 30% and offer better cost-effectiveness. They provide superior waterproofing, UV resistance, and thermal insulation properties.

Customization is available for various RV body components, such as side panels, roof panels, door panels, and partitions. Delivered as CKD kits for easy installation.

Advantages

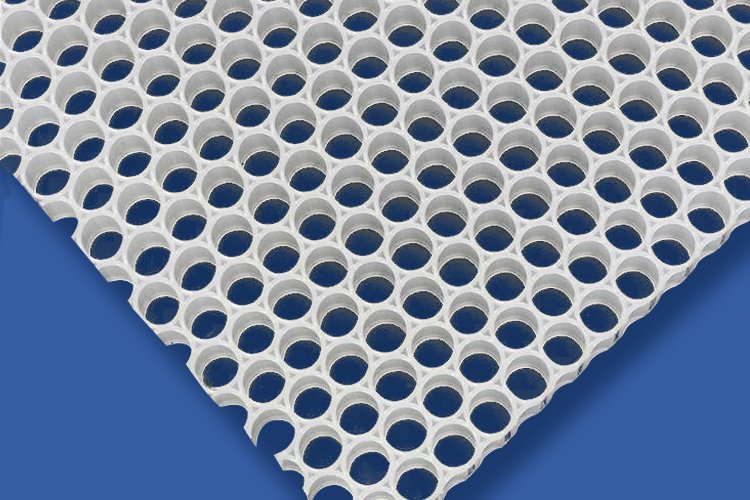

- Smooth

- Water- and moisture-resistant

- Scratch resistant

- Easy to work with.

- Long service life

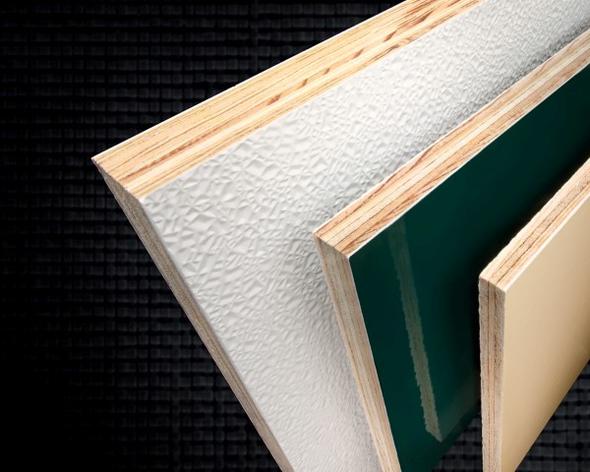

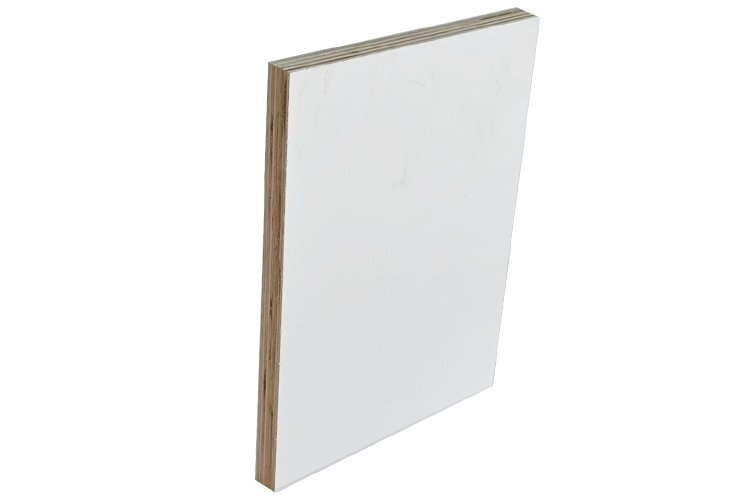

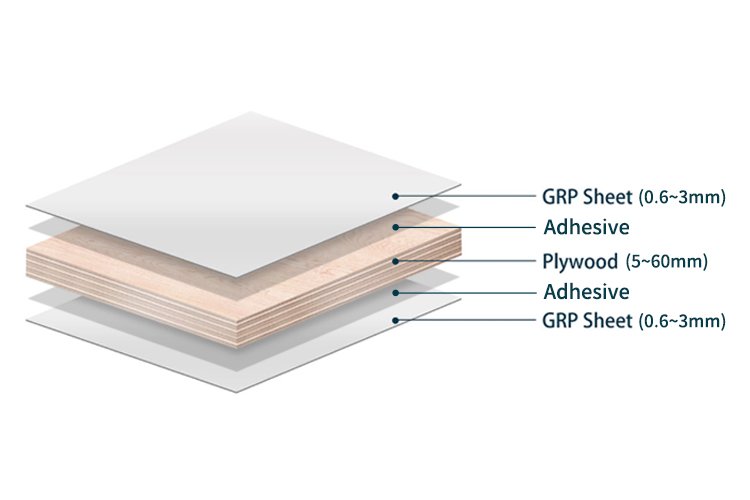

Structure

- GRP coated: The matrix of GRP is resin. This resin covers the exterior. It boosts waterproof performance, impact resistance, and bending resistance.

- Glue: High-quality glue that prevents gluing and cracking and provides good stability.

- Plywood: Plywood is manufactured by laminating layers of wood such as birch, pine, and oak. We offer plywood in thicknesses ranging from 7mm to 24mm. It is a material characterized by high strength, light weight, and excellent dimensional stability.

Specification

| Component | Specification |

|---|---|

| Skin | GRP (Glass Reinforced Plastic) |

| Core | Plywood, marine-grade plywood |

| Length | ≤ 11.8 m |

| Width | ≤ 3.1 m |

| Thickness | 5 mm – 60 mm |

Customized Processing

We provide a 100% customized service.

We can produce plywood in different lengths, widths, and thicknesses according to your application requirements.

CNC machining, cutting, drilling, and other customized processing services is available.

Application

GRP Plywood Panels applications:

- RV: travel trailers, Class C motor homes, teardrop trailers.

- Trucks: dry vans, trailers, and refrigerated trucks.

- Cabinetry: High-performance cabinet panels

- Architecture: Exterior trim, partitions, and ceilings

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.