Customize your trailer’s side panels.

Composite Box makes composite side panels and skins for trailers. It offers either gelcoat fiberglass or aluminum sandwich panels as side panels. The core layer uses insulation foam, plywood, or PP honeycomb. It is used for enclosed trailers, aluminum trailers, semi-trailers, camping trailers, cargo trailers, refrigerated trailers, and other applications. The maximum height is 3 meters, and the maximum length is 12 meters. It is easy to install and very strong, using a modular structure.

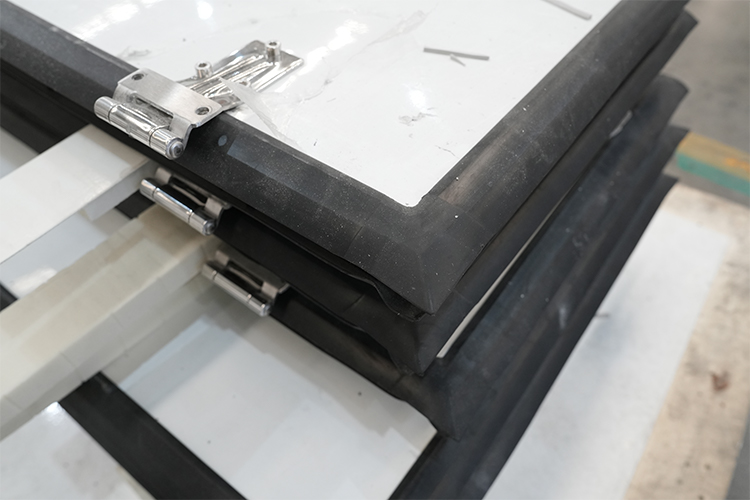

Our composite materials are the best for trailer side panels. They provide excellent insulation and impact resistance. We offer you customized trailer side panels and skins. We offer a wide range of RAL colors in addition to white and black. The thickness of the skin is from 0.7 to 5 mm and the total thickness is from 10~100mm. we can CNC cut, drill, and grind according to your requirements. We rigorously produce each trailer side panel for you.

Features

Our fiberglass composite side panels are ahead of other materials. They are very suitable for logistics and transportation to solve the last mile. We provide more than just a product, but also solutions to every customer’s concerns. Such as durability and aesthetics.

Our trailer side panels use high-performance composite panels that are perfect for replacing older side panels. Composite panels are better than plywood side panels. They insulate and look nicer. This can enhance your business’s image and cut costs.

- Wide range of uses: fully enclosed trailers, semi-trailers, camping trailers, refrigerated trailers, etc.

- Good impact resistance: using high-performance GRP or FRP skins.

- Easy to install: modular side panels, easy, and time-saving installation.

- Durability: composite side panels do not age easily and have a long service life.

- Strong load capacity: our composite side panels have a strong load capacity.

- Good corrosion resistance: fiberglass skin is not easily corroded.

- Chemical stability: can withstand a variety of chemical substances.

Get Free Quote of Fiberglass Side Panel For Trailer

Kits

- Wheel Retainer, Strap Kit

- E-Track Ratchet Strap Kit

- Trailer Steel Plate Conversion Kit

- Waterproof Trailer Tail Light Kit

- Trailer Hitch, Wheel Kit, etc.

vedio

parameter

| Parameter | Details |

|---|---|

| Length | 1.5m – 10m |

| Skin thickness | 0.7 – 5mm |

| Height | Up to 3 meters |

| Color | Common white or black |

Customizable

- Customize the high-performance fiberglass panels with additional features.

- CNC finishing, grinding, cutting, etc. are available.

- Reserve windows

- Coating treatments: anti-corrosion coating, zinc-chromium coating, epoxy coating

Application of Side panel for trailer

parameters

| Parameter | Details |

|---|---|

| Length | 1.5m – 10m |

| Skin thickness | 0.7 – 5mm |

| Height | Up to 3 meters |

| Color | Common white or black |

Customization options

- Customize the high-performance fiberglass panels with additional features.

- CNC finishing, grinding, cutting, etc. are available.

- Reserve windows

- Coating treatments: anti-corrosion coating, zinc-chromium coating, epoxy coating

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.