FRP Ceiling Panels Manufacturer

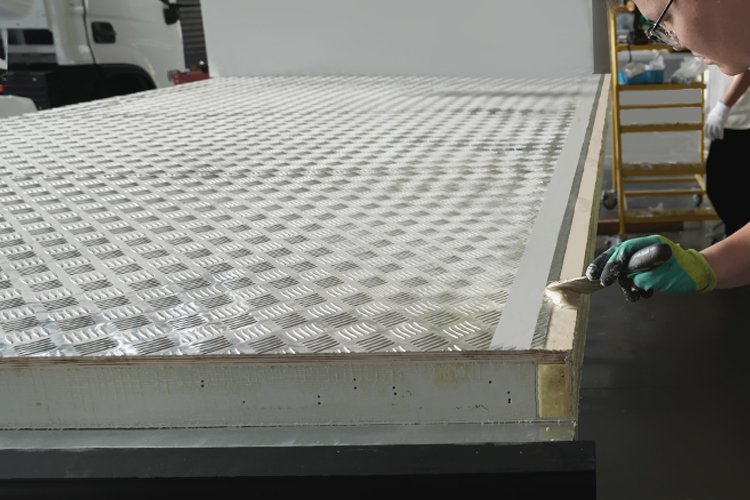

Composite Box is a professional composite FRP ceiling manufacturer with 10 years of experience. Made from fiberglass-reinforced plastic (FRP), our products utilize advanced lamination techniques to deliver exceptional properties including fire resistance, high strength, durability, moisture resistance, and corrosion resistance. Ideal for ceilings and walls, we offer a variety of textures and sizes. Contact our experts for more information.

- The ideal material for replacing outdated ceilings

- Providing solutions for hundreds of businesses over 10 years

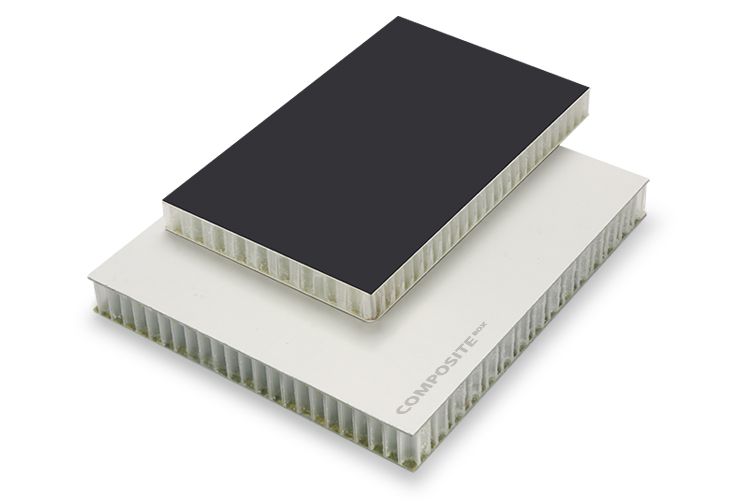

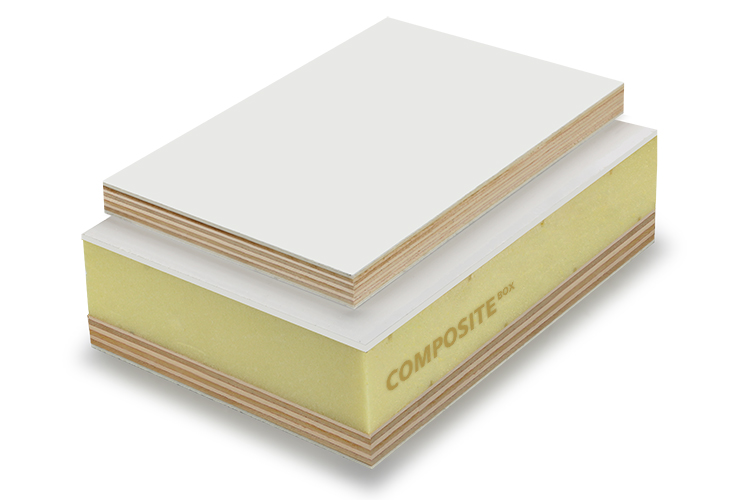

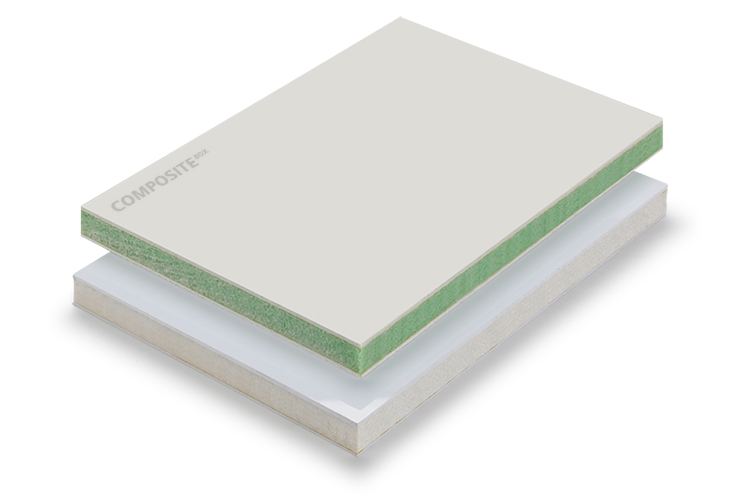

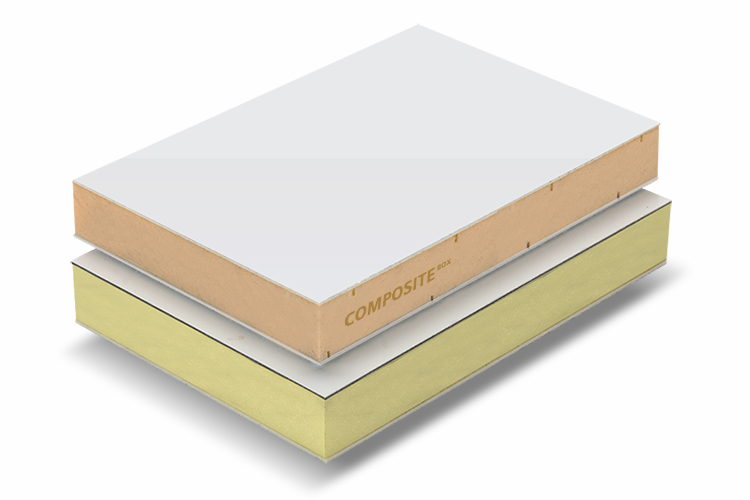

- Offering multiple core material options including XPS, PU, PET rigid foam, and plywood

FRP Ceiling Panels

FRP foam-core ceiling panels are highly suitable, offering both excellent thermal insulation and outstanding durability. Resistant to aging and corrosion over extended use, FRP composite materials represent the optimal choice. We provide a wide range of core materials, surface finishes, colors, and textures to meet all your decorative requirements.

We offer custom FRP ceiling solutions at competitive prices. Contact our experts today.

Below are selections from our product range:

Thermal Insulation FRP Ceiling Panels

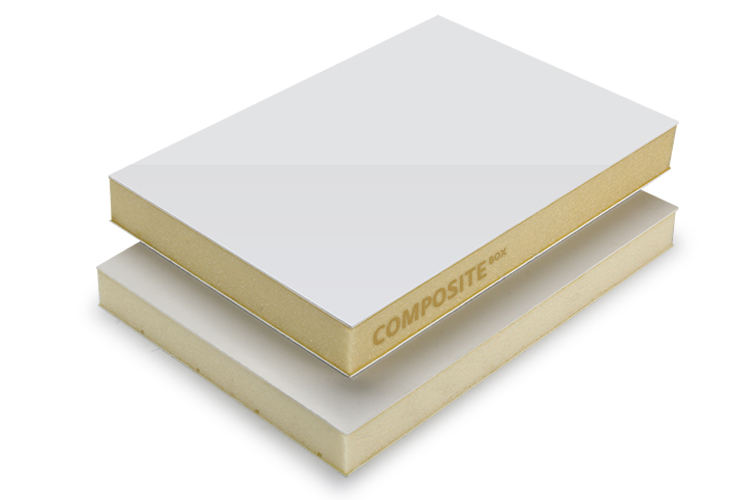

Featuring a polyurethane (PU) foam core layer, these panels effectively block heat transfer and conserve energy, making them ideal for cold storage applications.

2×2 FRP Ceiling Panels

Standard 2-foot × 2-foot modular dimensions for easy, flexible installation compatible with various framing systems. Features moisture resistance and corrosion resistance.

2×4 FRP Ceiling Panels

2-foot × 4-foot dimensions provide structural stability with precise joints and strong visual uniformity. Combines durability with practicality.

4×8 FRP Ceiling Panels

Large-format panels (4 ft × 8 ft) provide extensive coverage with minimal seams for a cohesive decorative effect. Ideal for factories and gymnasiums.

Black FRP Ceiling Panels

Features an elegant black surface for a sophisticated, modern aesthetic. Suitable for exhibition halls, restaurants, and theaters.

¿por qué elegirnos?

Satisfacción del cliente

Insistir en productos y servidores de alta calidad, centrados en la experiencia del cliente

Garantía de calidad

Controlamos estrictamente todos los procesos de producción para ofrecer a nuestros clientes una garantía de calidad fiable.

Línea de producción avanzada

La mejor línea de producción del mundo garantiza la precisión y eficacia del producto.

Personalización

Ofrecemos personalización 100%, lo que hace que los pedidos sean menos difíciles.

Custom FRP Ceiling Options:

• XPS: Extremely low water absorption, thermal insulation, suitable for humid environments

• PU: Exceptional thermal insulation properties, reduces energy consumption

• PET Rigid Foam: Recyclable, lightweight, suitable for most applications

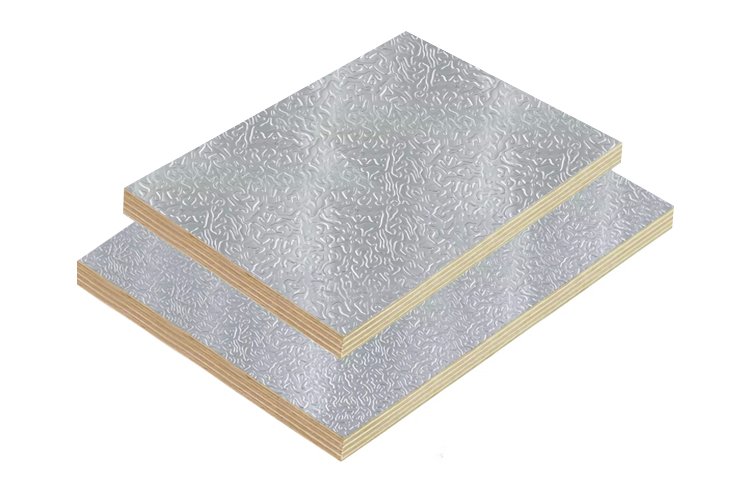

• Plywood: Provides ultra-high strength, bending resistance, and impact resistance.

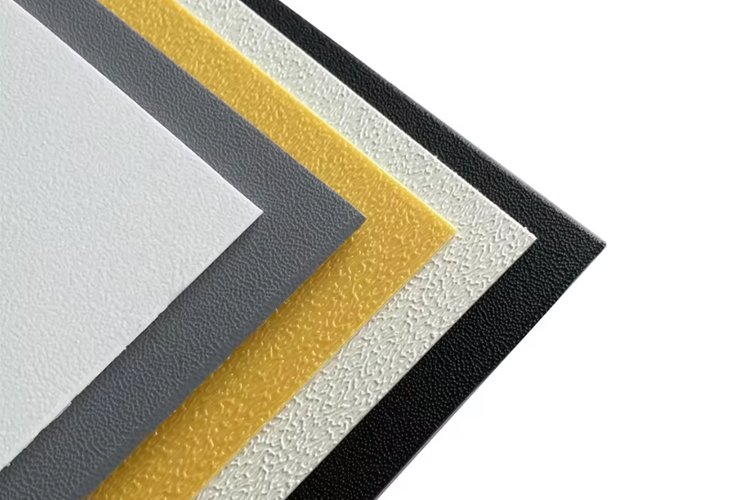

Supports custom tinting of gelcoat/pigment paste Standard Colors: Pure White, Ivory White, Light Gray, Beige Custom Options: Any RAL/Pantone color, vibrant hues, wood grain, metallic effects High weather resistance, fade-resistant; surface finishes include glossy or orange peel texture

- 600×600 / 600×1200 (Most commonly used, compatible with standard joists)

- 1200×2400 (4×8 ft, seamless full sheet)

- 1220×3050 / 1220×3660 (custom large sheets) Thickness: Single-ply 2–3mm, sandwich core 10–50mm adjustable (plywood core commonly 12–25mm)

Applications of FRP Ceilings

FRP ceilings are widely used in public spaces and specialized environments:

- Commercial kitchens, food processing plants, baking facilities

- Cleanrooms, pharmacies

- Swimming pools, bathhouses, restrooms

- Factory workshops, cold storage facilities

- Supermarkets, offices, hotels, schools

What are the advantages of FRP ceilings?

- Excellent moisture resistance

- Gran resistencia a los impactos

- Available in Class A or Class C fire ratings

- Quick and economical installation

- Superior corrosion resistance

- Easy maintenance and repair

HPL Sheet Applications

| Product Specification | Descripción |

|---|---|

| Nombre del producto | FRP Ceiling Panel |

| Superficie Material | Fiberglass Reinforced Plastic Panel |

| Total Sandwich Panel Thickness | 10-50 mm |

| Common Module Sizes | 600×600 mm, 600×1200 mm, 1200×2400 mm |

| Maximum Custom Size | 11.8 m × 3.2 m |

| Acabado superficial | Smooth, Textured, Customizable RAL Color Range |

| Installation Method | Modular installation compatible with standard grid systems |