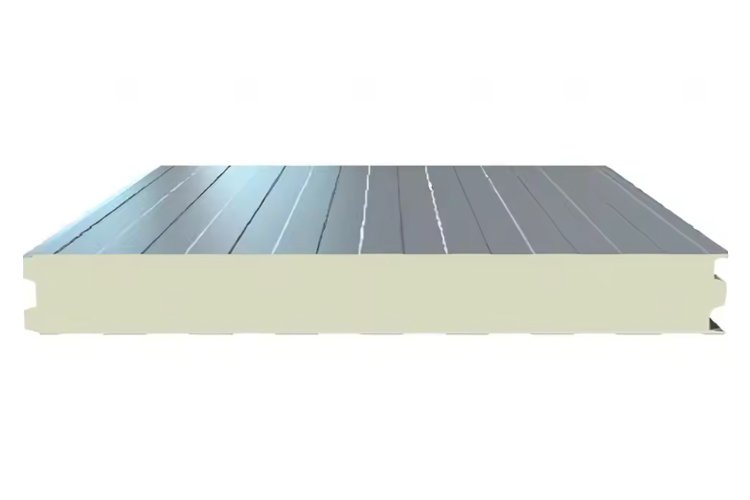

PUF Insulated Roofing Panels

PUF insulated roof panels, also known as PU roof panels, are the preferred material for prefabricated building roofs. Typically composed of metal sheets bonded with PU foam, they can also feature glass fiber or polycarbonate sheets as surface materials. Widely used in various buildings, cold storage facilities, commercial, and industrial settings, they employ a tongue-and-groove connection system for easy installation. We are an excellent supplier of PUF insulated roof panels.

Características

Our PUF roof panels can utilize either metal sheets or fiberglass as their outer skin. Their structure effortlessly withstands harsh weather conditions, including extreme temperatures, blizzards, typhoons, and other environmental factors. They enhance cargo temperature safety and improve occupant comfort.

Constructed with premium rigid PU foam panels, they deliver exceptional thermal insulation. Their lightweight design reduces structural load on buildings, minimizing safety risks. Simultaneously, they offer robust impact resistance with outstanding collision and compression tolerance. Excellent pressure dispersion properties are also inherent.

Get Free Quote of PUF Insulated Roofing Panels Manufacturer

Catalog

Póngase en contacto con

Related Products

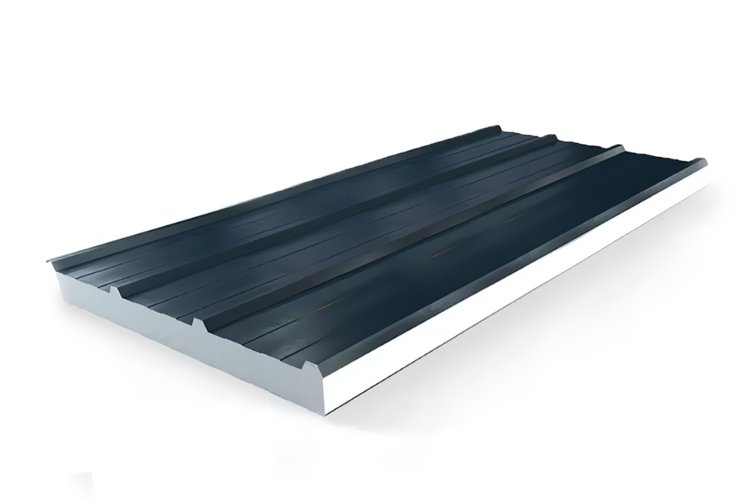

Corrugated Steel-Faced PUF Roofing Panels

Constructed with high-strength corrugated color-coated steel composite, offering superior drainage and exceptional load-bearing capacity. The preferred structural material for industrial plants and large warehouses, providing wind resistance, snow load protection, and compression strength.

FRP Glass-Fiber-Faced PUF Corrosion-Resistant Panels

Features a glass fiber outer layer for outstanding chemical corrosion resistance. Custom-engineered for harsh environments like chemical plants, livestock farms, and high-salt-fog areas.

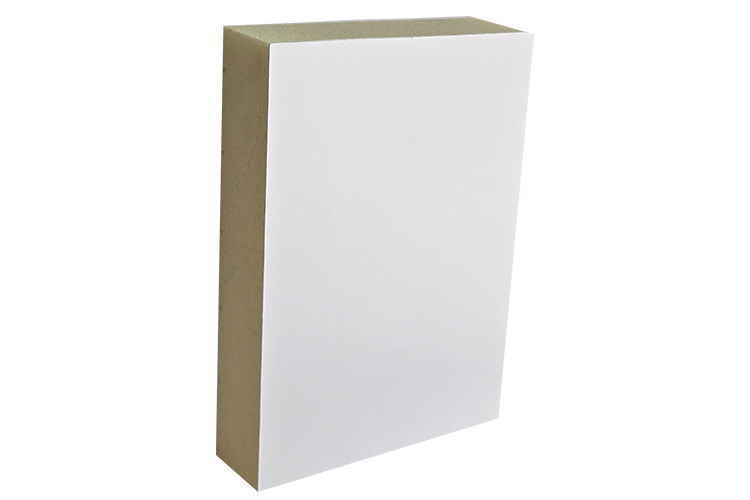

Cryogenic-Grade Thickened PUF Insulation Panels

Available in thicknesses up to 150mm with ultra-low U-values and sealed tongue-and-groove joints. Specially designed for food and pharmaceutical cold storage, delivering extreme thermal insulation to ensure energy efficiency and safety in sub-zero conditions.

Exceptionally high energy efficiency

Featuring PUF foam with a U-value as low as 0.298 W/(m·K), it is an ideal material for functional buildings. It resists chemical corrosion and is easy to process, transport, and install. A cost-effective building material.

Advantages of PUF Roofing Panels

Specifications for PUF Roof Panels

- Manufacturer: Composite Box Company

- Panel Thickness: 30mm, 40mm, 50mm, up to 150mm maximum

- Width: 1060mm

- Density: 36–42 kg/m³

- Thermal Conductivity: 0.024–0.03 W/m·K

Customization available upon request, with complementary services including CNC machining.

Aplicación

- Industrial plants

- Logistics warehouses

- Food cold storage

- Pharmaceutical cold chain warehousing

- Agricultural produce preservation facilities

- Sports venues

- Exhibition centers

- Airport terminals

- Railway stations

- Large shopping malls

- Supermarkets

- Automotive manufacturing workshops

- Chemical corrosion-resistant workshops

- Agricultural greenhouses

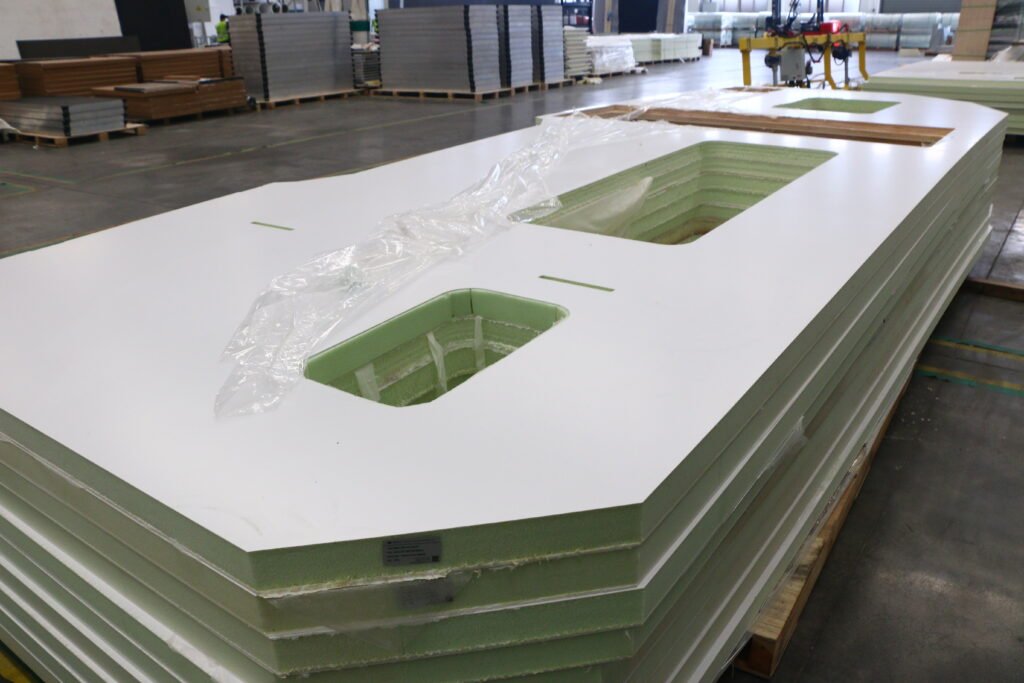

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

producto relacionado

¿por qué elegirnos?

Satisfacción del cliente

Insistir en productos y servidores de alta calidad, centrados en la experiencia del cliente

Garantía de calidad

Controlamos estrictamente todos los procesos de producción para ofrecer a nuestros clientes una garantía de calidad fiable.

Línea de producción avanzada

La mejor línea de producción del mundo garantiza la precisión y eficacia del producto.

Personalización

Ofrecemos personalización 100%, lo que hace que los pedidos sean menos difíciles.