FRP Wall Panels for Cleanrooms

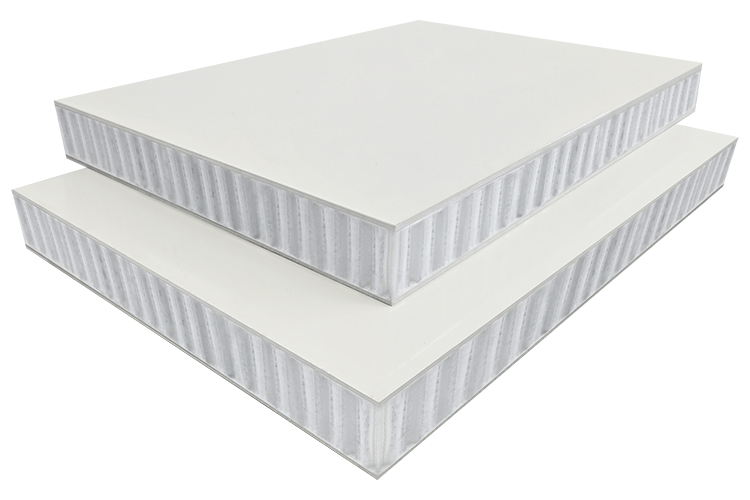

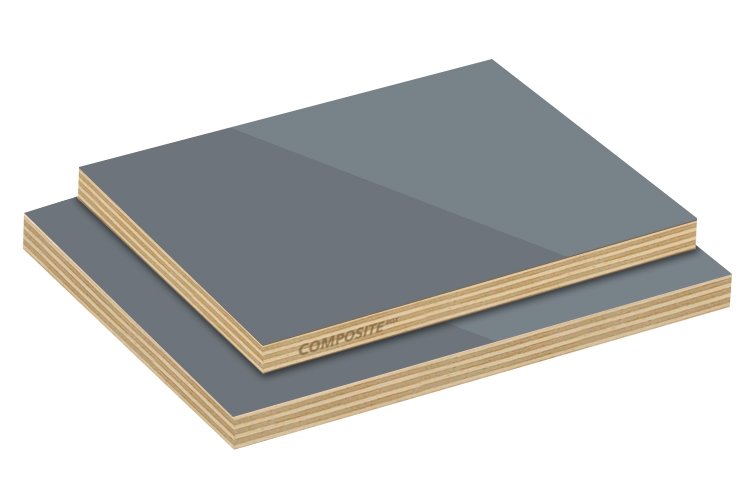

Composite Box offers customized FRP cleanroom wall panel solutions. Featuring food-grade gel-coated FRP panels with core material options including PU, PET, plywood, honeycomb, and more. Provides impact resistance and meets ISO 8 to ISO 5 cleanliness requirements. Exceptional antibacterial and anti-mold performance. Operates in extreme environments with resistance to strong acids and alkalis. Modular design ensures simple installation. Suitable for factories, pharmaceutical facilities, food processing plants, hospitals, and similar applications.

Características

We provide professional fiberglass cleanroom system panels, including wall panels, ceiling panels, and door panels. Panels are manufactured from fiberglass-reinforced plastic (FRP) or continuous fiber-reinforced thermoplastic (CFRT). Core materials include rock wool, polystyrene (EPS/XPS), PU, and more. Advanced hot-press composite molding is employed. Surface hardness exceeds 3H. With a service life surpassing 20 years, our panels resist cracking, yellowing, and aging. Using our panels ensures your cleanroom remains stable and as good as new for over two decades.

We offer custom sizing for both indoor and outdoor cleanrooms, designing according to actual application needs. We can incorporate doors, windows, and cable trays, utilizing CNC machining. Panels are available up to 2.8 meters wide and 11.8 meters long. Single panels extend up to 11.8 meters, significantly reducing seams. We also provide a complete range of accessories for one-stop procurement, including wall panels, ceilings, R50 curved inside/outside corners, return air sandwich panels, low wall return air columns, FFU mounting frames, double-layer tempered glass observation windows, airtight pass-through windows, and cleanroom rapid doors. Leveraging our comprehensive supply chain, all accessories can be sourced in one place, eliminating the need for multiple suppliers.

Obtener presupuesto gratuito de FRP Wall Panels for Cleanrooms

Catalog

Póngase en contacto con

The Importance of Cleanroom Panel Safety

Cleanroom safety is of paramount importance. Materials used must comply with relevant regulations. Our FRP panels employ Class A non-combustible fireproofing technology, ensuring no particle shedding. They also offer excellent antistatic properties and emit no gases, guaranteeing safety for any application.

Modular Design for Cleanrooms

Our FRP cleanrooms feature a modular design for streamlined installation. All wall panels, ceilings, frames, seals, and window frames are factory-precut and pre-drilled for immediate on-site assembly. Installation requires only screws and a power drill. The lightweight panels significantly reduce transportation and labor costs, delivering substantial savings.

Featuring concealed H-shaped aluminum alloy framing with an adjustable footing system, individual panels can be installed in as little as 6 minutes. A 4-person team can install 800-1200 square meters per day. Wall and ceiling panels interlock with precise 90° joints. Seams are permanently sealed with dual-component antimicrobial sealant for a seamless, integrated finish. Easily accommodates ±25mm floor leveling. The entire cleanroom is 100% demountable and relocatable, with material reuse rates exceeding 95%. A 1000㎡ ISO Class 7 cleanroom can be completed, inspected, and handed over in as little as 48 hours.

Product Advantages:

Antibacterial gel-coated FRP with bacterial adhesion rate below 0.1%

Complies with Class A fire resistance standards

Features fixed and interlocking installation designs

Achieves ISO Class 5-8 cleanroom standards

Parámetros

| Artículo | Detalles |

|---|---|

| Producto | Food-grade Antibacterial Gelcoat FRP Cleanroom Wall & Ceiling Panels |

| Core Material Options | PU, PET, Rock Wool, Honeycomb, Plywood |

| Cleanroom Class / Fire Rating / Antibacterial | ISO Class 5~8 A-grade Non-combustible Bacterial adhesion < 0.1% |

| Maximum Single Panel Size | Width 2.8 m × Length 11.8 m (Minimal joints) |

| Installation Speed | 6 min per panel 4 workers: 800–1200 m²/day 1000 m² project in 48 hours |

¿por qué elegirnos?

Satisfacción del cliente

Insistir en productos y servidores de alta calidad, centrados en la experiencia del cliente

Garantía de calidad

Controlamos estrictamente todos los procesos de producción para ofrecer a nuestros clientes una garantía de calidad fiable.

Línea de producción avanzada

La mejor línea de producción del mundo garantiza la precisión y eficacia del producto.

Personalización

Ofrecemos personalización 100%, lo que hace que los pedidos sean menos difíciles.