CFRT plywood sandwich panels manufacturer in china

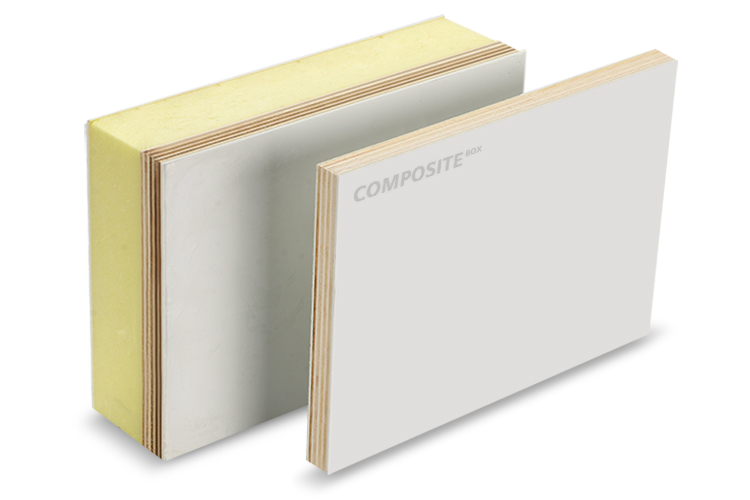

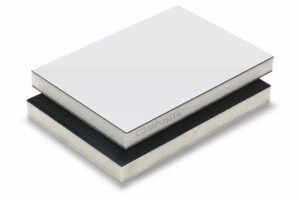

CFRT plywood sandwich panels are made of CFRT (Continuous Fibre Reinforced Thermoplastic – UD Tape) and plywood. They are laminated by high pressure vacuum using adhesive. These high-strength, corrosion-resistant composite panels are widely used where high strength and impact resistance are needed.

We are the top manufacturer of CFRT plywood panels. We offer OEM/ODM, 3D design, material selection, and other services.

Features

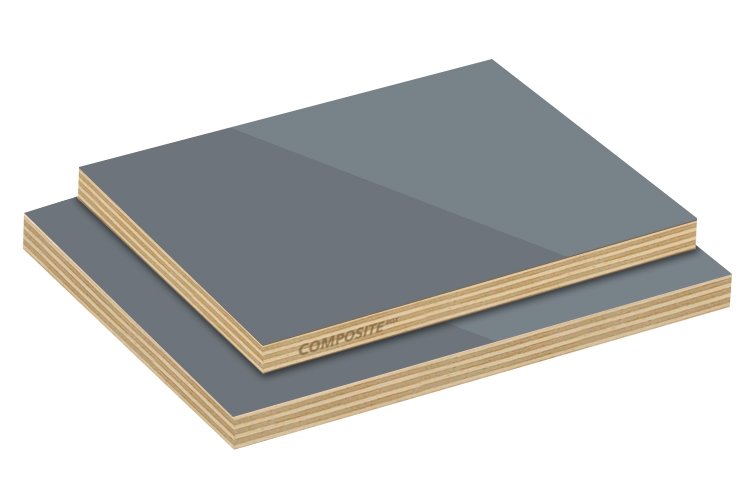

Composite Box is the best maker of CFRT sandwich panels. CFRT is made of multilayer UD tape. Plywood is made of laminated thin wood. Both are very strong and impact-resistant, as they are composite materials.

We can customize multiple layers of plywood. This will give it the right stiffness and strength. CFRT sandwich panels are a new, popular skinning material. They are strong yet lightweight and have the same features as CFRT.

feature:

- High-strength material, impact-resistant plywood is best suited for high-strength applications.

- CFRT skins are hard-wearing and less prone to cracking.

- CFRT is water- and moisture-resistant and prevents penetration of plywood.

- Flame retardant for added safety.

- Lower price than FRP, but is also more resilient.

- Easy CNC machining.

Get Free Quote of CFRT plywood sandwich panels

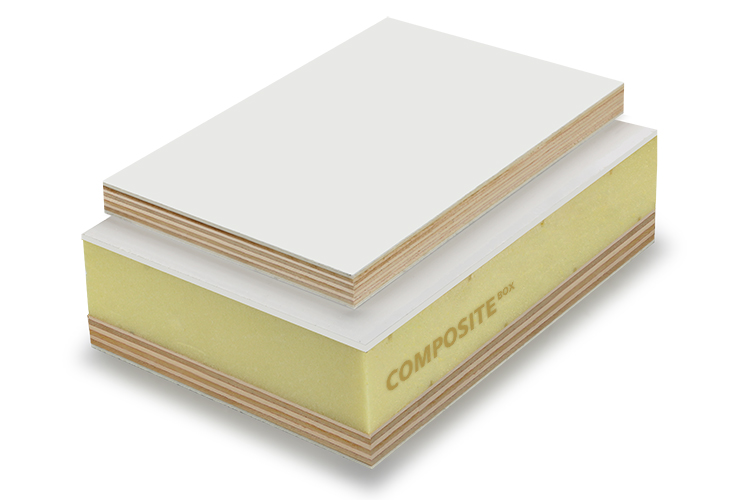

Structure of CFRT plywood sandwich panels

plywood

plywood is multiple layers of thin wood slices laminated by adhesives, with layers of interlocking fiber structure to provide excellent stability and durability.

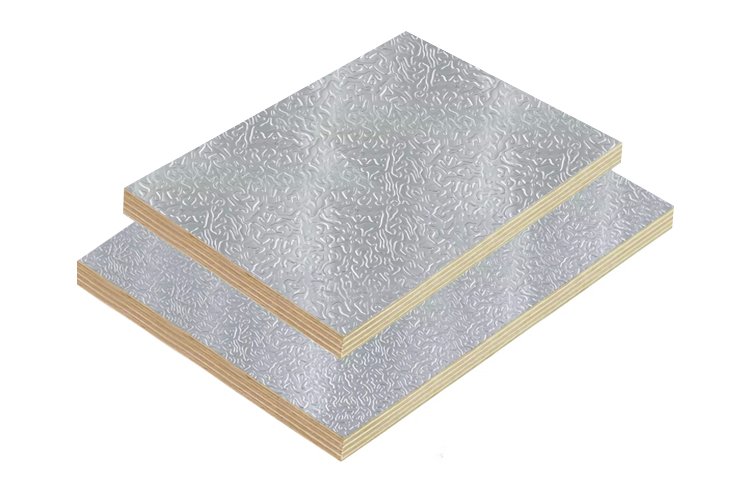

CFRT sheet

CFRT is a thermoplastic FRP sheet laminated with UD tape. It has excellent weather resistance, impact resistance and good resilience.

Application

- Dry van body

- Wall panelling, flooring, ceilings for caravans.

- Furniture manufacturing

- Caravans

- Tables

- Chairs

- Cabinets

Technical Parameters

| Item | Parameter |

|---|---|

| Skin Material | CFRT (Continuous Fiber Reinforced Thermoplastic), GRP (Glass Reinforced Plastic) |

| Core Material | Plywood (Poplar, Birch, Oak, Pine, Eucalyptus, Beech, etc.) |

| Thickness | 6.0 ~ 50mm |

| Width | Max 2.8m |

| Length | Max 12m |

| Surface Treatment | Glossy/Matt PET film |

| Strength | High strength, impact-resistant, strong compressive ability |

| Water Resistance | Moisture and water-resistant, prevents moisture penetration into the core |

| Flame Retardancy | Flame retardant, meets safety standards |

| Processing Method | Supports CNC machining, easy to customize |

| Weight | Lightweight material, maintains high strength while reducing overall weight |

| Customization Options | Size, surface treatment, embedded design, etc. |

Custom Processing

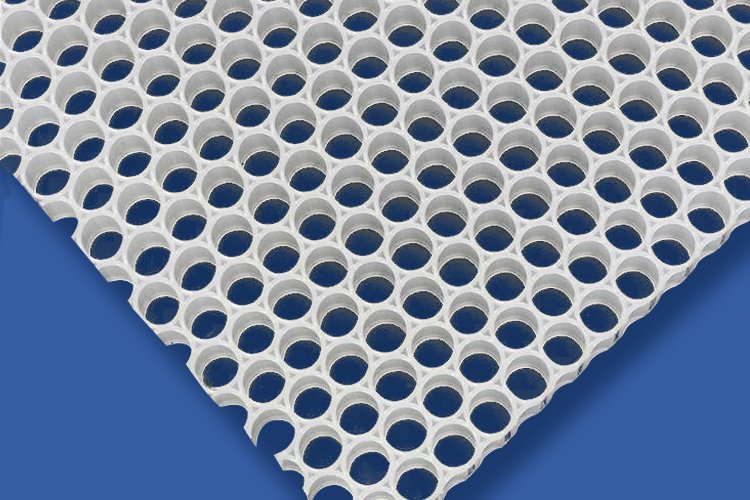

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.