Ultimate Guide: Truck Sandwich Core Materials

Sandwich Core for Composite Materials

Sandwich core is primarily used in sandwich panels. Also known as composite materials, it consists of multiple materials with different physical and chemical properties. It is mainly used in refrigerated truck bodies, dry cargo trucks, and small freight trailers. It enables the optimization of performance by combining the strengths of different materials. It offers a structural advantage, similar to building with blocks, allowing the formulation to be modified according to the required performance.

What is a sandwich core?

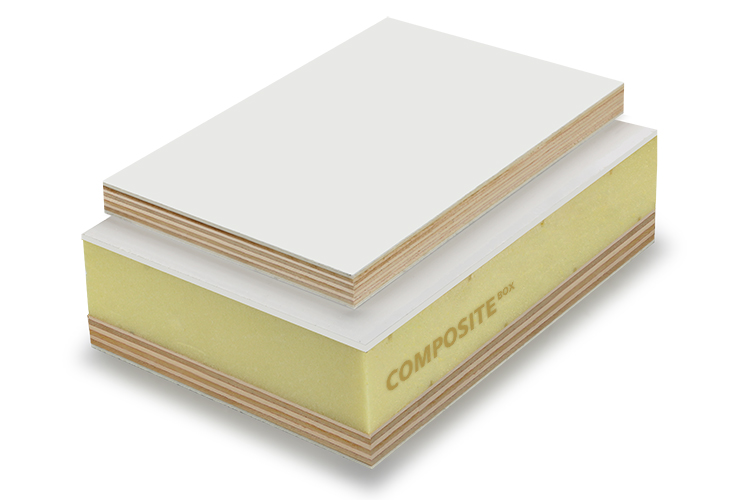

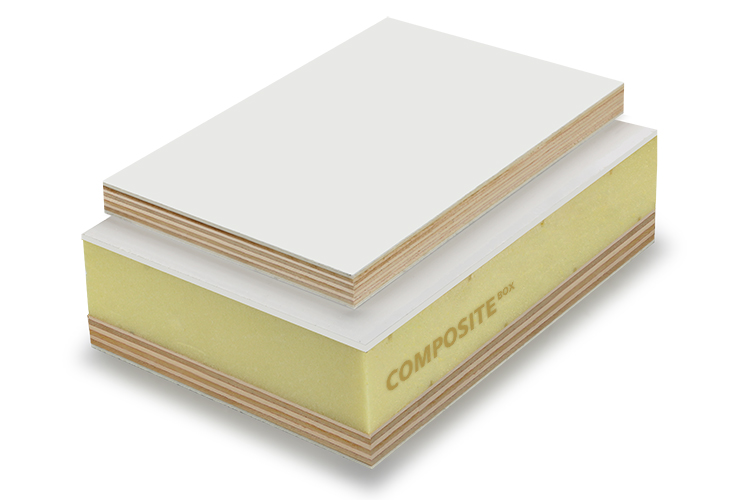

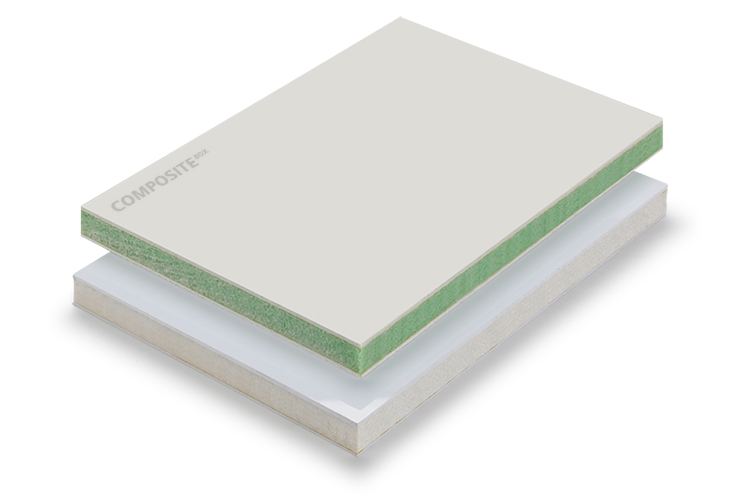

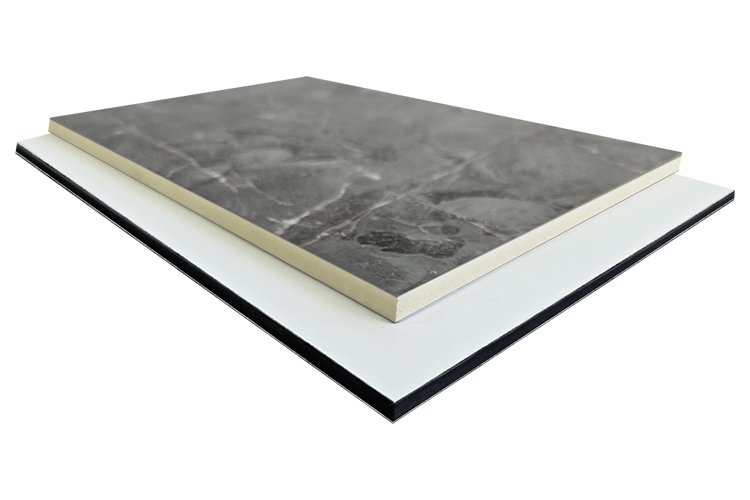

Sandwich Core

A sandwich core is the core material in a sandwich structure. It is typically bonded between two thinner panels or skins. Sandwich cores are generally thicker, less flexible, and provide structural support and rigidity. They offer compression resistance and load-bearing capabilities. Typically, sandwich cores provide insulation, soundproofing, and durability. They enhance the physical properties of the panels while reducing material waste and overall weight.Sandwich cores are typically composed of honeycomb cores, foam cores, or plywood.

Core types:

Foam core:

Foam cores are a cost-effective sandwich core option. They are lightweight and can be used in applications requiring thermal insulation, such as refrigerated vehicles, mobile homes, truck trailers, and building insulation structures. They are also used in the manufacture of ship hulls and aircraft fuselages and wings.

Polystyrene:

Foam cores made from polystyrene foam reduce the likelihood of moisture absorption. They have a closed-cell rate exceeding 99% and excellent thermal insulation properties. Their tightly sealed cellular structure contains no voids. They are suitable for rigid foam applications in trucks, aircraft, and ships.

Polyurethane foam: Polyurethane offers excellent thermal insulation, heat resistance, and flame retardancy.It is mainly used in the production of refrigerated truck bodies, heat-resistant materials, and small aircraft fuselages. It can be easily processed into various shapes.

PET foam:

Rigid PET foam boards are made from polyethylene terephthalate. They are recyclable. They have excellent compressive strength and bending strength.

PVC foam:

PVC foam boards usually come in high-density forms. They have excellent compressive strength and sound insulation properties.PVC foam is more cost-effective.

Phenolic

It has excellent fire resistance, extremely low density, and good moisture resistance, and is commonly used for insulation and floral arrangements.

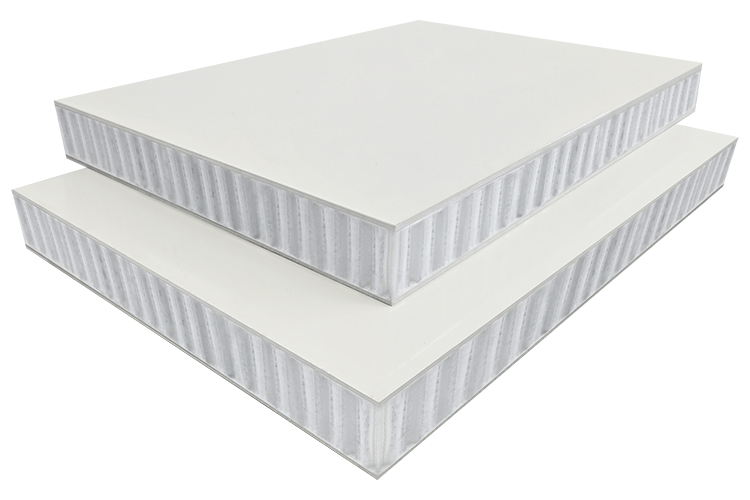

Honeycomb Core

Honeycomb core provides lightweight properties, significantly reducing weight. It has excellent pressure distribution performance. Its structural advantages enhance performance.

PP honeycomb core:

PP honeycomb core is a thermoplastic material with a circular open cell design produced from PP resin. It is a plastic sheet with very strong bending resistance. It is ideal for sandwich panel cores that require extreme lightness.

Plywood:

Marine-grade plywood is a high-quality core material with excellent water resistance and bending resistance. It is made by laminating multiple layers of thin hardwood and is a very strong material.