The Impact of Refrigerated Body Insulation on Cargo Safety

Thermal Insulation: The Cornerstone of Cold Chain Safety

In cold chain logistics, while refrigeration units are crucial, we believe the thermal insulation performance of refrigerated vehicle bodies is the decisive factor in safeguarding qqcargo integrity. Based on my 20 years of industry experience, during a 9-hour transport, heat loss due to inadequate insulation can account for over 30% of the refrigeration system’s total load.

We regard the insulation layer as a “mobile temperature-controlled safety chamber,” whose efficacy directly determines whether goods can maintain compliant, stable temperatures throughout the entire journey. The following are key challenges we must address:

- The depth of insulation’s impact on cargo safety

- Ensuring cold chain quality

- Controlling transportation risks

What dangers does insulation failure pose to your cargo?

I believe insulation failure can trigger severe consequences and chain reactions, causing significant cargo deterioration. The most critical impacts include:

- Cargo spoilage

- Value depreciation

- Food safety incidents

Temperature Fluctuations and Losses Cause Sustained Damage

Even brief temperature deviations can inflict irreversible damage. Composite Box manufacturers observe:

| Phenomenon | Impact Description |

|---|---|

| Accelerated Respiration | 10°C temperature rise increases respiration rate 2-4×, accelerating decay and nutrient loss. |

| Microbial Proliferation | Psychrophilic bacteria (e.g., Listeria) multiply rapidly in 0–8°C danger zone, creating food safety risks. |

| Altered Physical Properties | Freeze-thaw cycles form large ice crystals that damage cells, causing juice loss and poor texture. |

Frost and Condensation: The Hidden Dangers of Moisture

When cold air inside the compartment encounters poorly insulated panels, it condenses into water and eventually forms frost. We urge you to be aware of:

- Direct Contamination Risk: Condensation dripping may cause packaging (especially cardboard boxes) to become damp and warped, leading to label detachment and direct contamination of goods.

- Vicious Cycle of Energy Consumption: Excessive frost buildup on evaporators reduces heat transfer efficiency. To maintain temperature, the unit must operate more frequently and intensely, potentially increasing energy consumption by **15%-25%** while accelerating equipment wear.

Localized “Thermal Bridge” Effects: Uneven Temperature Distribution

Design flaws in structural frameworks or improper material joints create localized thermal shortcuts within cargo compartments—known as “thermal bridges.” Our experience shows these cause localized “hot spots” on compartment walls, leading to spoilage of adjacent goods (e.g., vaccines or premium seafood stored near edges). This results in undetectable “hidden losses.”

Where Do We See the Key to Improving Thermal Performance?

We view enhancing thermal performance as a systematic endeavor, centered on the precise integration of materials, structure, and manufacturing processes.

Core Materials: Our Focus on “Thermal Conductivity (K-Value)”

The K-value directly measures a material's insulation capability, measured in W/(m·K). Lower values indicate superior thermal retention.

Comparison of Commonly Used Insulation Core Materials:

| Parameter Name | Data Range |

|---|---|

| Box Length | 4.2m - 9.6m |

| Box Width | 2.2m - 2.5m |

| Box Height | 2.0m - 2.8m |

| Panel Thickness | 40mm - 80mm |

| Thermal Conductivity (K-Value) | 0.020 - 0.50 W/(m²·K) |

| Side Door Width | Single door up to 2.0m+ |

| Rated Load Capacity | Varies by design & chassis |

| Ambient Temperature Range | -40°C to +50°C |

| Assembly Time | 2-4 hours (modular design) |

We recommend that when selecting insulation materials, in addition to the K-value, you also consider their long-term stability, flame retardancy, and environmental friendliness.

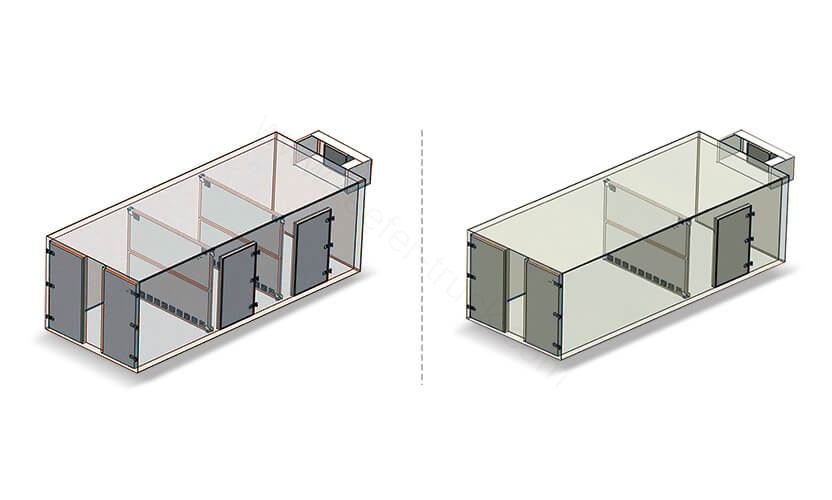

Structural Design: Blocking Thermal Bridges is Crucial

First, we employ a “sandwich” composite panel structure: utilizing high-strength fiberglass-reinforced plastic (FRP) or aluminum sheets as inner and outer skins, with polyurethane foam densely filled throughout the core. This structure achieves a unified balance of strength and thermal insulation. Second, our frame insulation design: We employ “thermal break” frames (e.g., using fiberglass connectors) or insert insulating spacers between the metal frame and inner/outer skins to completely block heat conduction pathways through the metal framework.

Craftsmanship and Integrity: We Believe Details Determine Success

We understand that superior insulation relies not only on the panels but also on a flawlessly sealed system. We meticulously control critical areas like body panel joints and door seals, employing premium gaskets to ensure “zero” cold air leakage. Our data indicates that a poorly sealed rear door can cause up to 40% of total cold air loss. Therefore, from design to construction, we treat seal integrity as the lifeline safeguarding your cargo's temperature stability.

What advantages does our stable insulation system offer?

We believe an efficient, stable insulation system delivers far more than just “insulation”—it drives comprehensive operational improvements.

Direct Economic Benefits: Tangible Cost Savings

- Energy Efficiency & Reduced Consumption: Significantly reduces refrigeration unit load

- Increased Revenue: Polyurethane (PU) insulation panels weigh over 20% less than steel bodies

- Reduced Maintenance Costs: Lower failure rates and extended service life

Enhanced Operational Reliability and Compliance

- Handling Extreme Conditions: Our insulation system provides a wider safety buffer for interior temperatures during summer heat exposure or winter cold snaps, minimizing cargo risks.

- Ensuring Temperature Stability During Loading/Unloading: Frequent door openings severely test insulation layers. Our high-performance insulation effectively delays cabin temperature recovery, buying valuable time for loading/unloading operations.

- Meeting Stringent Regulations: Our refrigerated truck solutions provide the hardware foundation required for continuous, stable transport temperature recording compliance with GSP (Good Storage Practice), HACCP (Hazard Analysis Critical Control Point), and other standards.

Enhance Brand Credibility and Market Competitiveness

Ensuring goods arrive in optimal condition is key to earning long-term trust from premium clients. Additionally, extend value: a reliable fleet is your core asset for delivering high-quality cold chain services and commanding premium pricing.

How to Evaluate Refrigerated Truck Insulation Solutions?

Based on our experience, when evaluating numerous products, establish a scientific assessment system to avoid decisions based solely on thickness or single parameters.

Define Your Requirements: Backtrack Technical Standards from Cargo Needs

We recommend first determining insulation levels based on the most stringent requirements of the transported goods.

Our recommended insulation solution selection reference:

| Cargo Type | Recommended Temperature | K-Value Requirement | Our Special Recommendations |

|---|---|---|---|

| Vaccines, Biologicals | 2°C - 8°C | 0.25 W/(m²·K) | Ultra-low K-value materials, thermal bridge-free design, temperature monitoring verification required |

| Frozen Foods | -18°C and below | 0.30 W/(m²·K) | Focus on material stability at low temperatures to prevent brittleness |

| Fresh Produce, Dairy | 0°C - 4°C | 0.40 W/(m²·K) | Emphasize condensation prevention and humidity control |

| Ambient Delivery (Insulation Needed) | 15°C - 25°C | 0.50 W/(m²·K) | Primarily prevent solar heat gain, focus on material weatherability |

Conducting Full Life Cycle Cost Analysis

We recommend using the “Total Cost of Ownership” model for decision-making: TCO = Initial Purchase Cost + (Average Annual Energy Cost + Average Annual Maintenance Cost) × Expected Service Life. Based on customer feedback, a body with 15% higher initial cost but superior insulation typically recoups the difference within 2-3 years through fuel and maintenance savings, generating net profits thereafter.

On-site Inspection and Testing Verification

- Visual Inspection: We recommend examining corners of older models for signs of condensation or rust.

- Temperature Distribution Testing: With the vehicle unloaded, run the refrigeration unit to the set temperature. Use a multi-point temperature logger to monitor temperature uniformity throughout the cargo compartment (especially at the center and corners of all six surfaces). Temperature variation should be controlled within **±2°C**.