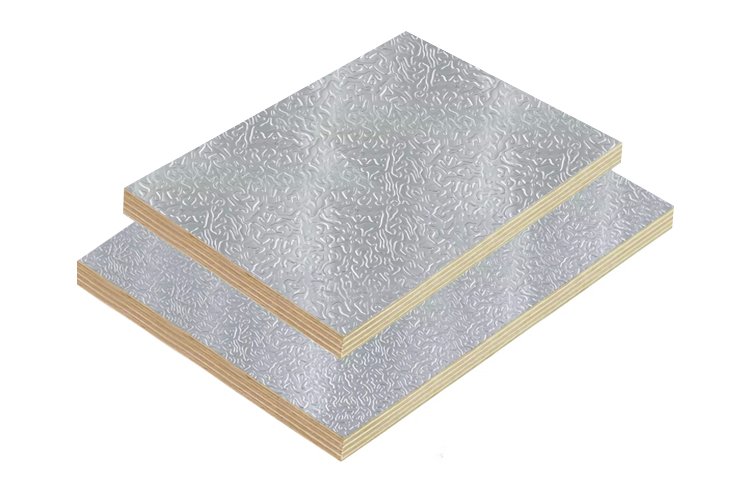

Aluminum Faced Plywood Panels

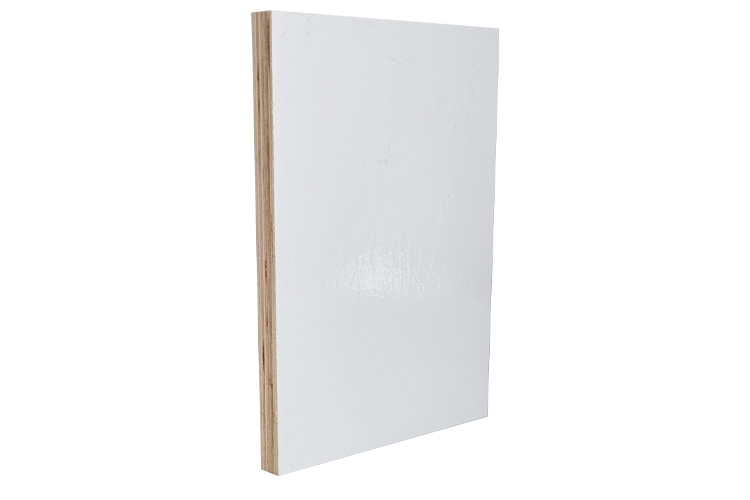

Composite Box is a professional manufacturer of aluminum-faced plywood, utilizing durable aluminum sheets as the outer layer and wood-based plywood as the core material. We offer standard sizes including 4×8, 4×10, 5×8, and 5×10 feet, with thicknesses ranging from 1/4 inch to 3 inches. Our products meet Class A fire-rated standards and are available in multiple surface finishes including black and white. They are widely used in trailer bodies, truck cargo compartments, building exteriors, sheds, and temporary housing construction.

Features

Aluminum-faced plywood is a high-performance composite material that perfectly combines strength and fire resistance. The surface layer uses 1050, 1060, or 1100 series aluminum alloy sheets, while the core consists of 9 to 18 layers of high-grade plywood. The aluminum alloy panel offers exceptional corrosion resistance and weather resistance. It features lightweight construction, excellent bending strength, rust prevention, wear resistance, and resilience against harsh weather conditions.

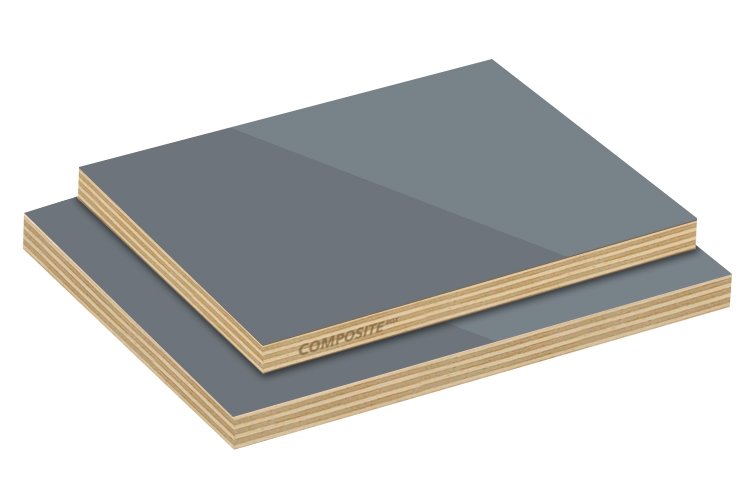

Composite Box offers sizes ranging from 4 feet to 10 feet. It meets diverse requirements for decorative cladding, trucks, and construction. Custom colors are available per the RAL color chart; surface finishes include polished, brushed, sandblasted, embossed, and more.

Get Free Quote of Aluminum Faced Plywood Panels

Advantages

- Durability: Highly corrosion-resistant, rust-proof, withstands weathering and UV exposure.

- Low Maintenance: Requires no upkeep, outlasting standard wood panels.

- High Strength: Offers superior rigidity and bending resistance while remaining lightweight.

- Fire Resistance: Class A fire rating with flame-retardant properties, reducing fire hazards.

- Aesthetic appeal: Smooth, flat surface with vibrant colors for an attractive appearance.

- Construction convenience: Easily cut, drilled, and processed.

Specifications

- Common sizes: 4 ft x 8 ft; 4 ft x 10 ft; 5 ft x 8 ft; 5 ft x 10 ft. (Custom sizes available)

- Thickness range: 1/4 inch, 1/2 inch, 3/4 inch, 1 inch, 1.5 inches, 2 inches, 3 inches. (Other thicknesses available upon request)

- Surface Material: Color-coated aluminum alloy panels.

- Core Material: Grade plywood.

- Fire Rating: Class A.

- Standard Colors: Natural aluminum, white, black. (Other colors available upon request)

Applications

- Transportation Equipment Manufacturing: Used for trailer bodies, truck cargo boxes, and RV shells to achieve lightweight construction with high structural integrity.

- Building Facades and Roofing: Serves as exterior wall cladding, roof underlayment, and interior partitions, balancing aesthetics with durability.

- Temporary and Mobile Structures: Ideal for rapid assembly of site offices, exhibition booths, and shelter tents.

- Interior Finishing and Furniture: Suitable for contemporary decorative walls, counter facings, and custom furniture.

- Industrial and Warehouse Facilities: Used for workshop partitions, warehouse door panels, shelving dividers, and various protective panels.

Customization Options

- Custom lengths, widths, and special thicknesses available upon request.

- Multiple surface finishes offered, including glossy, matte, and embossed patterns.

- Custom RAL color coatings available beyond standard black and white.

- Aluminum sheet thickness and plywood core grades adjustable to meet strength requirements.

- Supports pre-drilling, slotting, cutting, and other processing services for incoming materials.

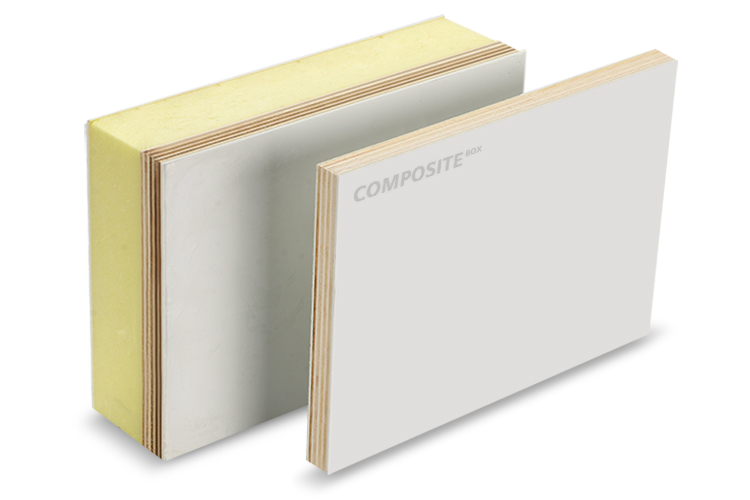

- Can incorporate functional core materials for thermal insulation, soundproofing, and other applications.

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.