Rock Wool Sandwich Panel Manufacturer&supplier

Rockwool sandwich panels are fire-resistant and sound-insulating materials. Constructed with rockwool fibers, they feature outer skins made of galvanized steel sheets, fiberglass panels, or aluminum sheets. Suitable for roofs, exterior walls, and interior acoustic wall panels. We offer a variety of rockwool sandwich panels with custom production available.

- Fire Resistance: Fire endurance rating of 120–240 minutes

- Sound Insulation: Reduces noise levels by up to 35dB

- Thermal Insulation: Thermal conductivity of 0.043 W/(m·K)

Rock Wool Sandwich Panel

We provide premium rock wool sandwich panel solutions. Over 20 specifications have been developed. Below are our standard styles. If your specific requirement is not listed, please contact Composite Box.

Below are selections from our product range:

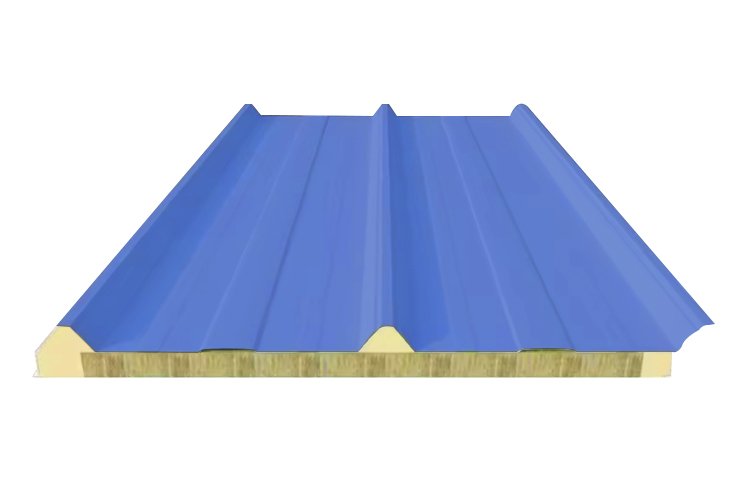

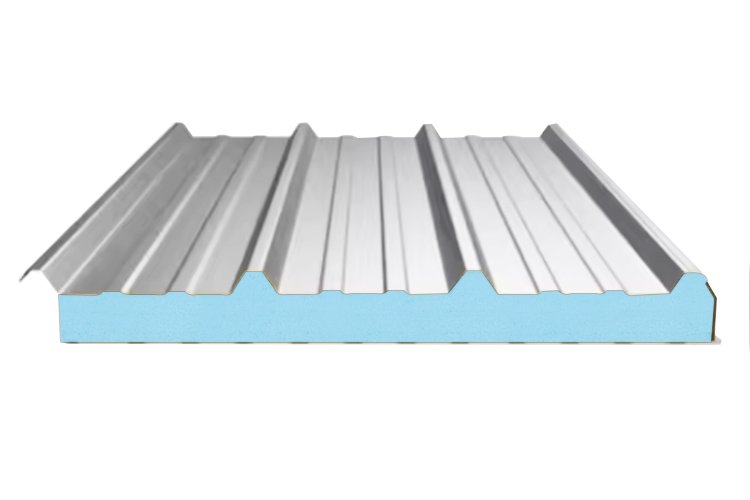

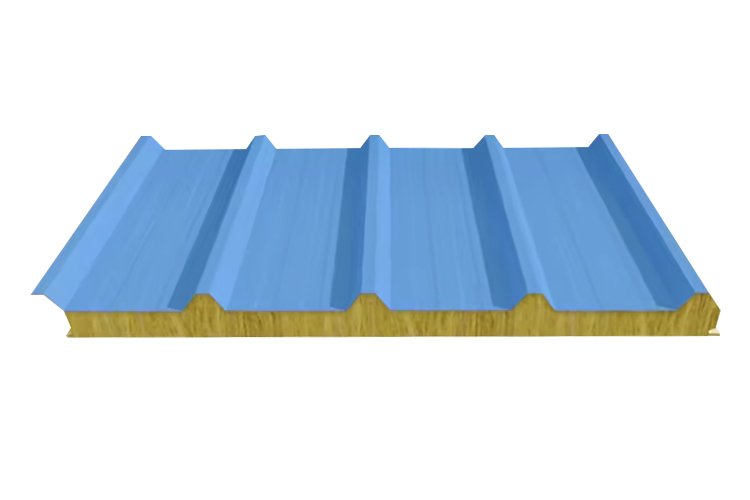

Roof Fireproof Rock Wool Sandwich Panels:

For roofing applications, featuring thermal insulation properties. Available in white, silver, and other colors. Various end joint configurations provided.

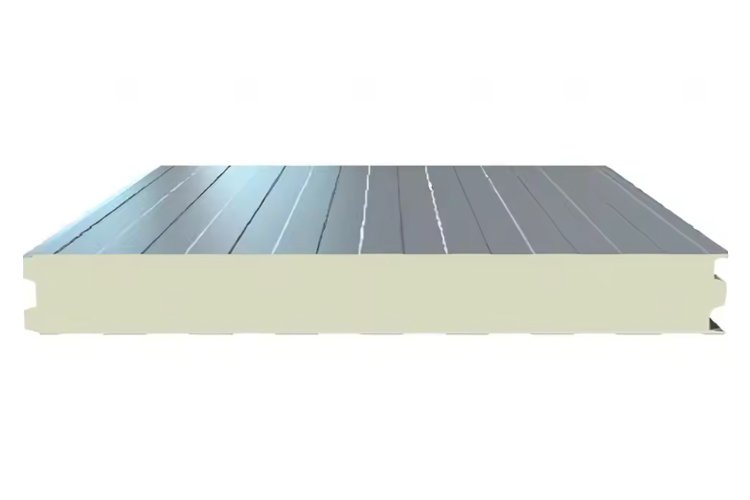

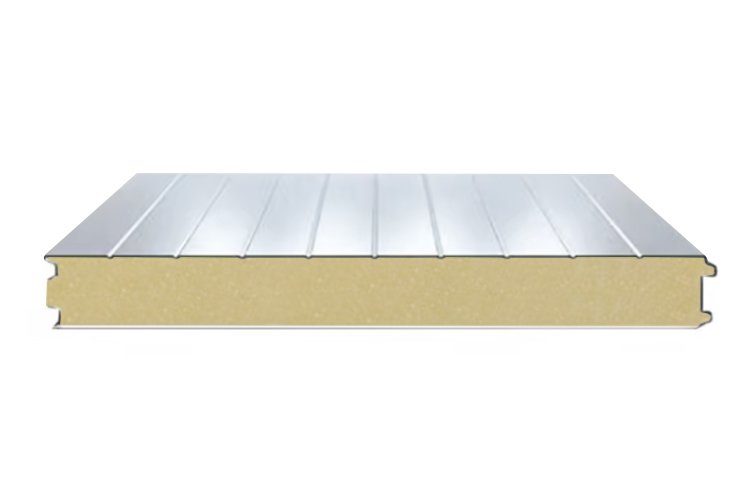

Polyurethane Rock Wool Sandwich Panels:

Rock wool core with polyurethane (PU) edge sealing and galvanized steel sheet facings. Suitable for industrial plants, buildings, and marine applications.

300 mm Rock Wool Sandwich Panels

300 mm thick rock wool core panels, Class A non-combustible, with superior thermal and acoustic insulation. Suitable for factories, cold storage facilities, and similar structures.

Metal Wall Rock Wool Sandwich Panels

Designed for metal stud systems, thickness 50–120 mm, with custom color options available. Ideal for public buildings.

Rockwool Acoustic Wall Panels:

Rockwool core + black microporous surface layer achieves noise reduction up to 38 dB.

why choose us?

Wind Resistance

Class A non-combustible, fire resistance 120–240 minutes

Thermal & Acoustic Insulation

Thermal conductivity 0.0438, noise reduction up to 35–38dB.

Custom R&D

Over 20 specifications, supporting personalized production.

High Strength & Durability

Polyurethane edge sealing, waterproof and pressure-resistant, long-lasting performance.

Product Specifications

| Parameter | Specification |

|---|---|

| Core Material Density | 80 kg/m³, 100 kg/m³, 120 kg/m³, 140 kg/m³, 150 kg/m³ |

| Panel Thickness | 50 mm, 75 mm, 80 mm, 100 mm, 150 mm, 200 mm |

| Effective Width | 950 mm, 960 mm, 1150 mm |

| Length | Customized (common ≤12 m, max ≤18 m) |

| Fire Rating | Class A (A1/A2) |

| Thermal Conductivity | 0.035 W/(m·K), 0.040 W/(m·K), 0.043 W/(m·K) |

| Sound Insulation | 30 dB, 35 dB, 38 dB |

| Steel Sheet Thickness | 0.4 mm, 0.5 mm, 0.6 mm, 0.8 mm |

| Panel Thickness (mm) | Fire Resistance Limit (min) | Sound Insulation (dB) |

|---|---|---|

| 50 | 30–60 | 28–32 |

| 75 | 60–90 | 30–35 |

| 80 | 60–90 | 32–36 |

| 100 | 90–120 | 34–38 |

| 150 | 120–180 | 36–40 |

| 200 | 180–240 | 38–42 |

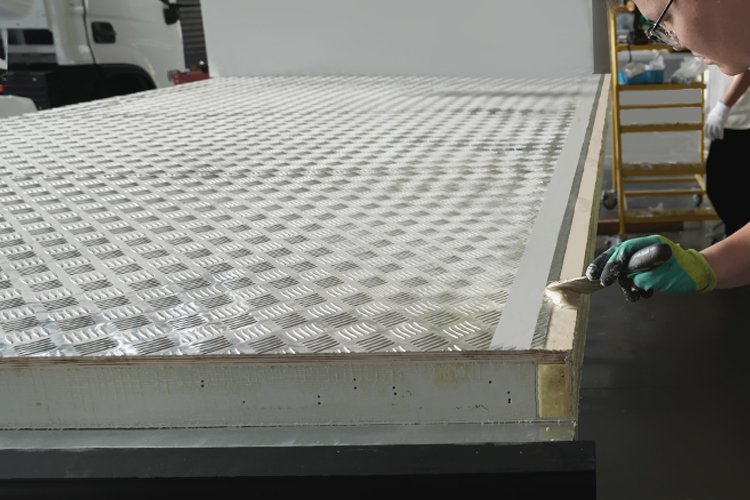

What processing services do you offer?

Composite Box is a premier manufacturer of rock wool sandwich panels, providing precision machining and CNC services. Our service offerings include:

- Custom Cutting: Precise panel cutting according to drawings.

- Opening and Slotting: Creating openings and slots for pipes, wiring, or doors/windows.

- Edge Processing: Customizing and sealing various overlap edge types.

- Lamination/Coating: Applying protective films or specialized coatings to metal facings.

- Pre-assembly: Bundling accessories with panels for expedited installation.

Application Scenarios

Rock wool sandwich panels are widely used in modern construction due to their excellent fire resistance, thermal insulation, and soundproofing properties. They are primarily suitable for:

- Industrial plants, warehouses, workshops

- Logistics centers, shopping malls, exhibition halls

- Cold storage facilities, food processing plants

- Schools, hospitals, gymnasiums, and other public buildings

- Cleanrooms, laboratories

- Exterior walls, roofs, interior partitions, etc.