Custom Prefabricated House Sandwich Panels

Prefabricated wall panels are a popular modular building material today. They are suitable for temporary housing, mobile homes, and portable buildings. We offer various types of prefabricated sandwich wall panels using materials such as fiberglass-reinforced plastic (FRP), aluminum sheeting, and foam. We continuously upgrade our technology and quality to provide you with premium design and manufacturing services.

Features

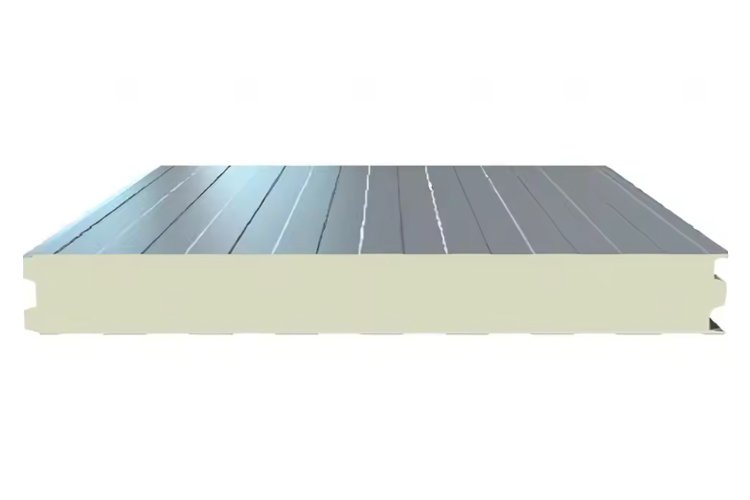

Using prefabricated wall panels enables rapid construction of diverse building types and styles. We offer roof panels, wall panels, and more, featuring a prefabricated modular design. The benefits include easy installation without requiring reinforced concrete. Assembly is completed through simple interlocking. Our multiple advanced sandwich panel production lines allow flexible combinations of materials like fiberglass, foam cores, and steel skins to customize the optimal panel structure based on your insulation, fire resistance, and strength requirements.

Our panels offer numerous advantages. Beyond being easy to install and transport, they provide thermal insulation and aesthetic appeal. They also deliver excellent soundproofing and fire-resistant properties, ensuring the completed structure offers superior comfort and reliability.

Our dedicated team of technical engineers and sales professionals provides comprehensive support throughout your project.

Get Free Quote of Prefabricated House Sandwich Panels

Advantages of Selecting Prefabricated House Wall Panels

Efficiency

Reduces material waste by over 40%

Cost

Saves over 30% in construction expenses

Reliability

Delivers over 20% improvement in overall performance compared to traditional sandwich panels

Related Products:

EPS Sandwich Panels

EPS sandwich panels feature color-coated steel sheets or aluminum sheets as facings, with EPS foam as the core material. Weighing only one-tenth of traditional masonry, they are classified as ultra-lightweight building materials. They offer thermal insulation properties for energy efficiency while achieving Class A or B1 fire resistance.

PU Glass Wool Sandwich Panels

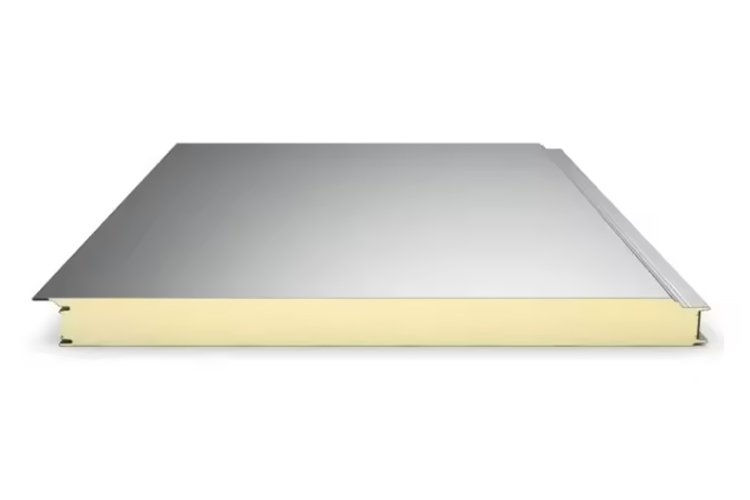

PU glass wool sandwich panels utilize high-density glass wool as the core material. Both sides feature color-coated steel sheets or FRP panels. High-strength rigid polyurethane serves as the secondary core material. They provide fire resistance and thermal insulation properties. Suitable for conventional mobile structures, they offer high strength and durability.

Rock Wool Sandwich Panels

Rock wool sandwich panels utilize basalt as raw material. They are Class A non-combustible rock wool, representing the highest fire resistance among sandwich panels. They offer superior fire resistance, thermal insulation, and soundproofing. They are the preferred material for roofing, exterior walls, and fire compartment walls.

Polyurethane Sandwich Panels

Polyurethane sandwich panels deliver exceptional thermal insulation, making them highly suitable for cold chain logistics warehouses, temperature-controlled workshops, and cold storage wall panels. Their thermal conductivity ranges from 0.018–0.023 W/(m·K). They possess outstanding fire resistance and excellent wind pressure resistance and impact resistance.

Application Areas

Prefabricated sandwich wall panels are widely used in temporary housing, factory buildings, container homes, and portable buildings.

Parameters

| Customization Item | Available Options | Recommendation / Note |

|---|---|---|

| Wall Panel Type | Prefabricated house wall panel (sandwich panel structure) | Default product for all series |

| Core Material | EPS / Rock Wool / Polyurethane (PU) / PU+Glass Wool | Rock wool = best fire resistance PU = best insulation |

| Panel Thickness | 50 / 75 / 100 / 120 / 150 / 200 mm | 100 mm most popular, best cost-performance ratio |

| Facing Material | 0.4–0.8 mm color-coated steel (any RAL color) / FRP / Stainless steel | 0.5 mm color-coated steel most economical & durable |

| Effective Width | 950 mm (rock wool) / 1000 mm / 1150 mm | 1000 mm gives highest coverage and least waste |

| Length | Custom cut, maximum 11.8 m (fits 40ft container) | Precisely cut according to drawings or container size |

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.