FRP Exterior Wall Composite Panel

Composite Box specializes in providing FRP flat panel exterior wall composite panels. Featuring Class A fire resistance and low thermal conductivity. Surface utilizes weather-resistant gelcoat + high-strength glass fiber reinforced skin. Customizable sandwich core structures available, with core material options including XPS foam, PU, plywood, etc. Offers various surface treatments and finishes, such as marble patterns, brushed metal, embossed textures, and other premium finishes. Lightweight yet high-strength, they serve as an ideal alternative to color-coated steel and aluminum panels.

Suitable for exterior walls in residential kitchens, bathrooms, factories, and mobile housing units. Lightweight and durable, they fully replace traditional color-coated steel and aluminum panels. We provide high-quality, design-oriented flat FRP panels for exterior walls.

Features

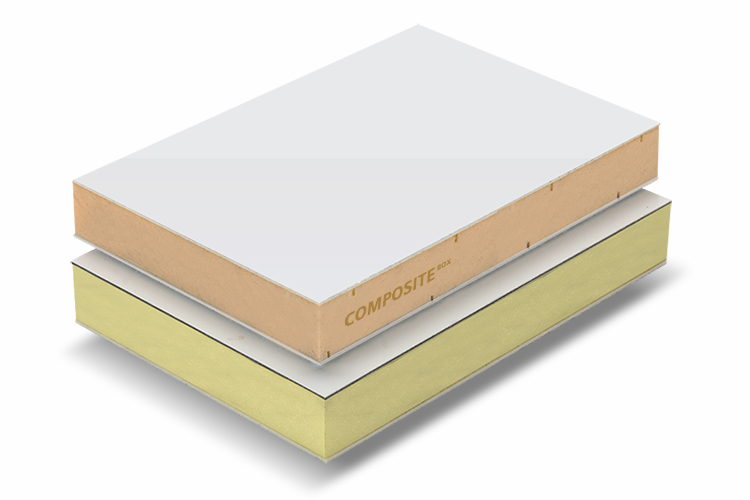

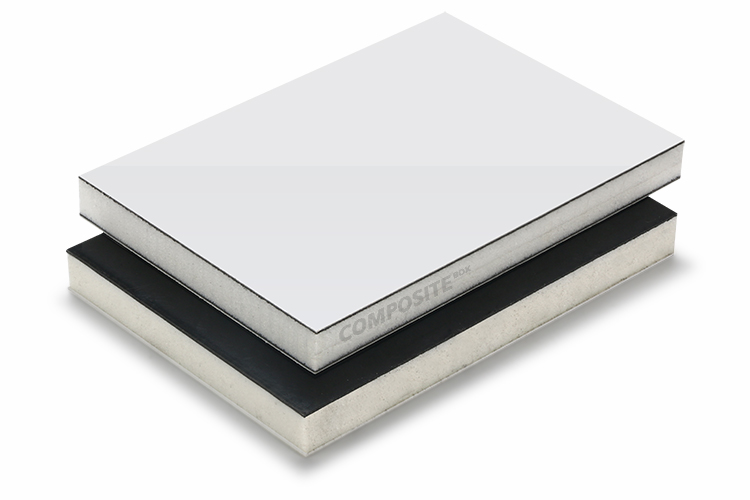

Our FRP foam composite panels are specifically designed for high-standard exterior wall systems. The surface features a durable FRP gelcoat panel ranging from 1.2 to 2.0 mm thick. Core materials can include XPS, polyurethane, plywood, or PP honeycomb in thicknesses from 10 to 200 mm. Utilizing an imported continuous hot-press composite process ensures a flat panel surface and strong bonding, significantly reducing the risk of cracking during later stages. With a thermal conductivity as low as 0.024 W/m·K, our exterior FRP panels offer exceptional wind pressure resistance. They can be enhanced with Class A fire-retardant coatings to meet high-rise building code requirements.

Our FRP exterior panels support multiple installation methods. Custom interfaces can be tailored to specific needs, accommodating dry-hanging on metal studs, back-bolting, or direct bonding with structural adhesives.

Get Free Quote of FRP Exterior Wall Composite Panel

Product Advantages:

- 20-year service life: Exceptional aging resistance and superior physical properties

- Low maintenance costs: Minimal upkeep required, cost-effective

- Aesthetically pleasing: Over 30 finishes available

- Weather Resistance: Resists acids, alkalis, salt spray, and extreme temperatures

- Significant Energy Savings: Low U-value (as low as 0.18) reduces energy consumption

- Total Cost of Ownership: Over 30% lower than aluminum panels

- UV Stability: UV-stabilized formulation prevents accelerated aging

More Customization Options

- Insulation Core Materials: XPS, PU, Rock Wool, Plywood, PP Honeycomb, etc.

- We offer various thicknesses

- Panels can be cut to size and CNC machined per requirements

- Direct shipping to construction sites available

- Multiple RAL colors and surface finishes provided

- Single panels up to 12 meters in length

- Optional functional coatings: Class A fire retardant, antibacterial, mold-resistant, self-cleaning, etc.

Exterior Wall Applications

- Industrial plants, logistics park facades

- Food/pharmaceutical/electronics cleanroom facility exteriors

- Curtain wall cladding for commercial complexes and office buildings

- Exterior walls for schools, hospitals, and sports arenas

- Exterior wall systems for prefabricated buildings and passive houses

- Rapid renovation of old factory buildings and historic structures

- Salt-resistant exterior walls for coastal buildings

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.