Rigid PU Foam Insulation Foam

PP honeycomb flooring is a composite material consisting of vinyl wood-grain flooring and a PP honeycomb core. It combines the advantages of PP honeycomb cores and solid wood flooring, offering the benefits of lightweight, low cost, and long service life. It is suitable for indoor use, as well as in RVs and trucks.

Product Description

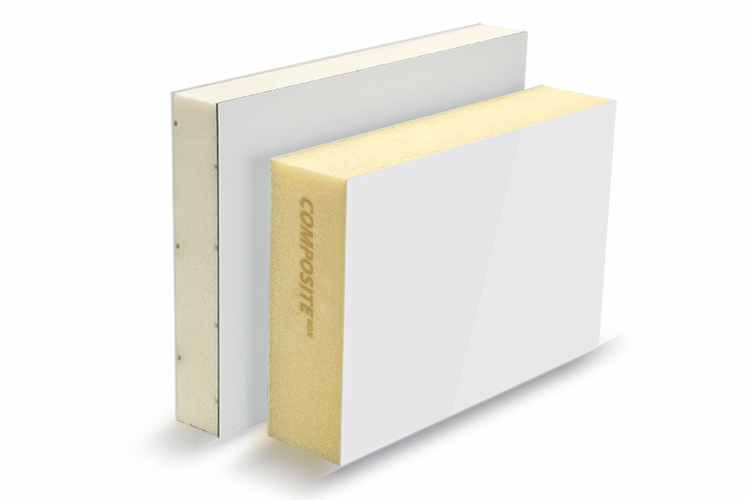

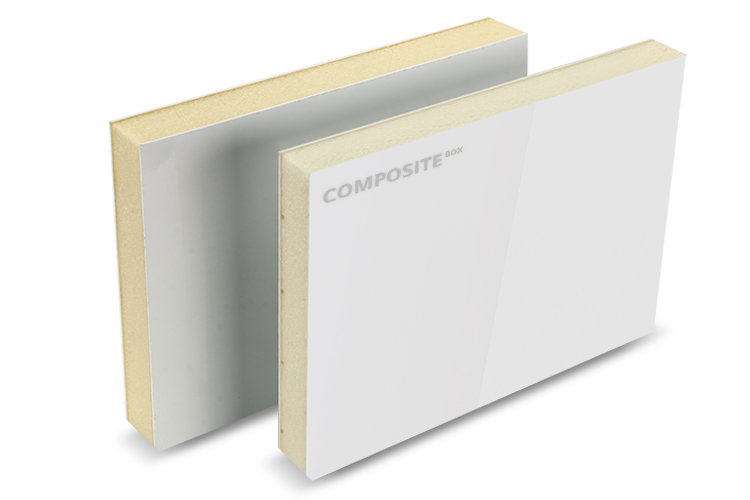

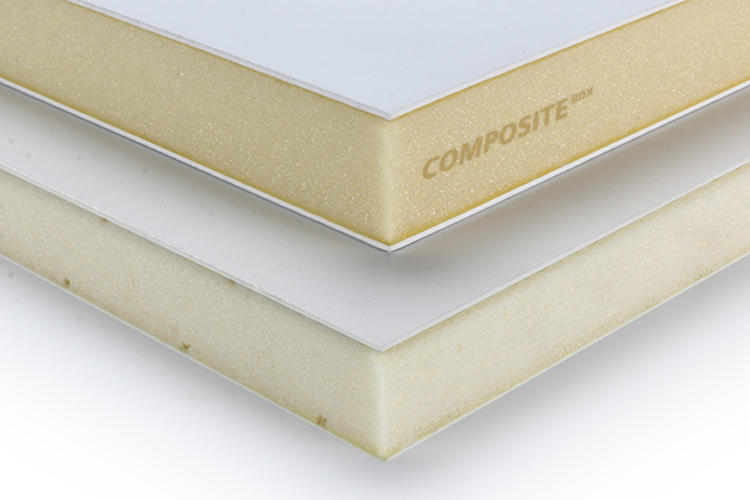

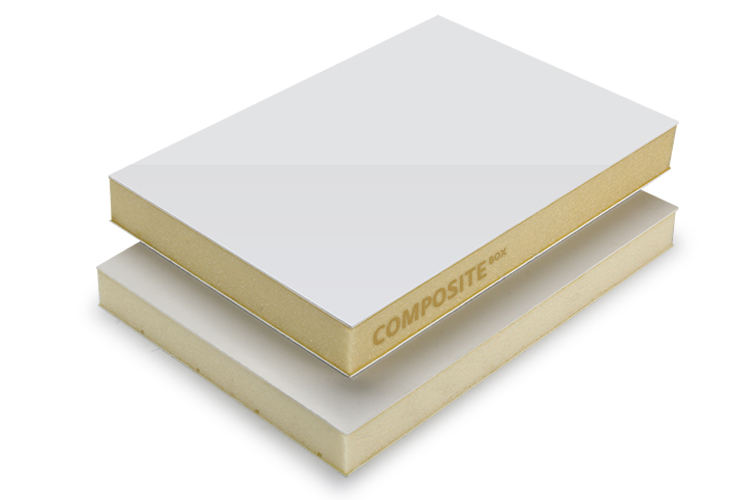

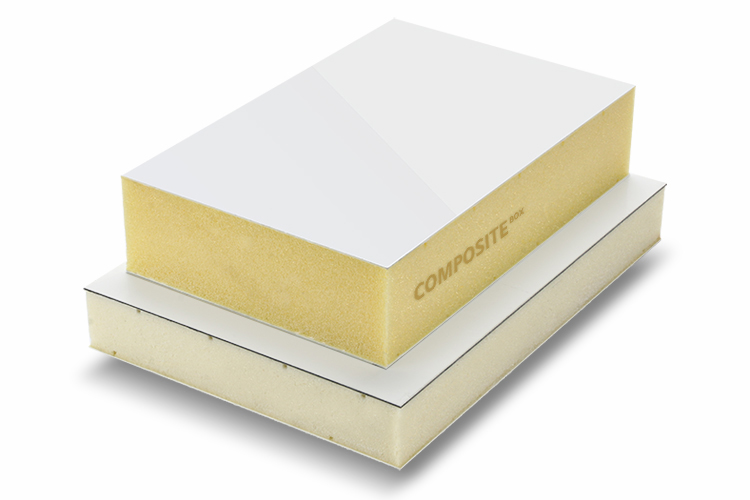

Rigid polyurethane foam boards are also known as PU or PUR. They are a type of rigid insulation foam and fire-resistant foam. With a thermal conductivity of 0.022–0.028 W/m/K, they feature a closed-cell structure, offering excellent insulation and fire-resistant properties. They are CFC-free. In everyday use, they are virtually unaffected by thermal expansion and contraction, making them resistant to cracking and breaking. They are durable and have a long service life. For insulation applications, waterproofing treatment is sufficient, with a water absorption rate of ≤0.2%. It has a very low density, ranging from 32 to 65 kg/m³. We can manufacture both low-density and high-density PU foam. This reduces weight, making it suitable for refrigerated trucks and recreational vehicles.

In use, it can be bonded with most materials. The most common application is in composite panels with fiberglass sheets. PU foam has an excellent strength-to-weight ratio, making it suitable for load-bearing structures and the production of composite panels. It is the preferred choice for most building insulation applications.

Parameter

| Parameter | Description |

|---|---|

| Product Name | Rigid polyurethane foam insulation |

| Thermal Conductivity | 0.022–0.028 W/m/K, excellent insulation. |

| Density | 32–65 kg/m³, lightweight material. |

| Structure | Closed-cell, great for insulation and fire resistance. |

| Temperature Range | -38°C to 118°C, performs in extreme conditions. |

| Fire Resistance | Flame-retardant, forms charcoal to stop fire spread. |

| Hardness | 25–70 Shore A, durable and maintains shape. |

Get Free Quote of Rigid PU Foam Insulation Foam

advantages

- Low thermal conductivity: The thermal conductivity coefficient is lower than that of PVC, XPS, PET, and other rigid foams, and has been recognized by the market.

- Low density: The density of PU foam is as low as 35 kg/m³, making it an excellent lightweight material.

- High durability: It can maintain temperature under extreme conditions and withstand temperatures ranging from -38°C to 118°C.

- Fire-resistant performance: PU foam is a flame-retardant foam with a melting point above 250°C. During combustion, it forms charcoal, thereby preventing the spread of flames. It does not produce harmful gases.

- Easy to process: PU foam is easy to process and can be machined using CNC carving and cutting.

- High hardness: It does not deform and maintains its shape over the long term. Shore A hardness ranges from 25 to 70.

Structural polyurethane foam

PU foam is an excellent structural foam, suitable for use in buildings, railways, ships, refrigerated trucks, and cargo vehicles. It can be produced as a composite material or used as a filling foam. In structural foams, PU foam holds nearly a dominant position.

FAQ

Applications

PU foam boards are also known as insulation boards or structural foam. They have a wide range of applications. They are commonly used in building insulation, refrigerated truck panels, composite materials, ship hull structures, insulated sandwich panels, mobile homes, and more.

Custom Processing

Embedded Reinforcement Structures

To enhance strength and functionality, reinforcement materials can be embedded within composite panels. Options include plywood, aluminum alloy profiles, GRP tubes, steel structural components, and more.

Multi-Material Composite Processing

We specialize in composite processing of materials such as FRP, CFRT, and foam cores, delivering superior performance while meeting diverse application requirements.

High-Precision CNC Machining

Advanced CNC machining centers enable high-speed precision cutting, complex contour milling, drilling, and more.

Edge Processing

Edge finishing and connector integration are performed according to specific requirements. Services include edge wrapping, chamfering and grinding, waterproofing, and embedded nuts.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.