Quality Marine Plywood Manufacturer

Marine-grade plywood is made from thin layers of hardwood. These layers are laminated in cross, parallel, and perpendicular grain patterns. Waterproof resin glue is used to bond them together. A protective coating is applied. It offers waterproof and anti-microbial features. Plus, it has high strength and resists warping. It can also endure tough marine conditions. Marine plywood is available in AA grade, AB grade, BB grade, MDO, and HDO.

If you are choosing high-quality marine plywood, you can trust us. Our plywood is lightweight and easy to work with. It comes in beech, pine, Douglas fir, and striped teak. This makes it great for wood structures like marine hulls, furniture, decks, doors, and outdoor projects.

- Thickness: 5,6,8,10,12,15,18,20,25mm

- Grade: AA, AB, BB, MDO, HDO

- Air-drying (moisture content): ≤9%

- Standard: BS1088 grade

- Specific gravity: 500KG/m³

- Standard size: 1525х1525 (5х5), 1220х1525 (4х5), 1250х1525 (4х5), 1525х1250 (5х4)

- Glue: waterproof resin glue

- Tolerance: ±3 mm

We offer specifications for all thicknesses and sizes, large production volumes and reduced costs.

Features

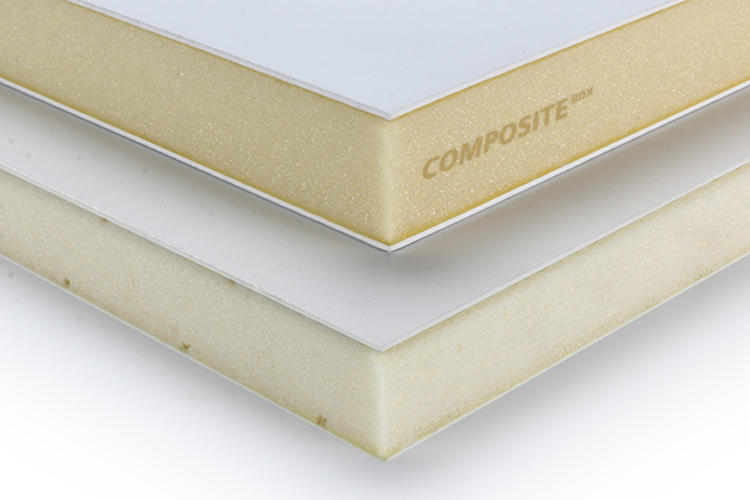

Composite-box provides a broad selection of marine-grade plywood. We choose high-quality woods with few defects. Our plywood is cut evenly and sanded multiple times. This ensures uniform thickness and minimal gaps, with core gaps no larger than 1 mm. And reduced weight. It uses a high-quality waterproof coating for improved performance and durability. Enabling reliable durability despite any exposure to moisture. So ours is quality plywood.

We have high standards for plywood production. We conduct many quality checks on logs, veneers, gluing, and laminating. In fact, we go beyond the industry BS-1088 standard. We carefully select our A-grade products. We use strong hardwoods that have attractive patterns. When we prime and varnish them, the colors look rich and modern.

Our plywood is polished many times to give a smooth touch, with no roughness, and it lasts for a long time.

Get Free Quote of Quality Marine Plywood

Advantages of marine plywood

- Waterproof resin glue, enhance waterproof ability

- Neater and more beautiful appearance

- Excellent corrosion resistance

- Resistant to ant and termite infestation

- Service life can be more than 20 years.

Product Grades

Grade A-A: Standard

A-A grade marine plywood is the best quality available. It has a great look and feel. This plywood is cut perfectly, with no knots. It offers top performance and is the finest choice for your needs. It is suitable to be used in places where waterproof performance and appearance are more important, such as hulls of ships, cabinets, interiors, furniture, and so on. It also has the following properties:

- Perfect appearance experience.

- Top waterproof performance

- Better durability

A-B: Standard

A-B grade plywood is also a high quality marine plywood that has only minor defects such as slight knots that do not prevent it from functioning. Very cost effective, very durable and moisture resistant. Ideal for applications such as timber frame construction and marine.

- Excellent water resistance

- High quality durability

- Long service life

B-B: Standard

B-B grade marine plywood isn’t as visually appealing as A-A or A-B grades. However, it focuses on durability and strength. Its main goal is to perform well in applications.

However, it may have some knots and other defects. But after the cross-bonding of the waterproof resin adhesive and our advanced production process, it can still have better waterproofness and can remain durable and stable in high-strength applications. It can be used in applications where the appearance is not very demanding. For example, interior paneling, flooring, etc.

Medium Density Overlay (MDO)

Specialty Marine Plywood

Coated with a resin-impregnated fiber layer that significantly improves both waterproofing and surface finish

- Better waterproofing

- Durability

- Paint friendly

High Density Overlay (HDO)

MDO can be used on the exterior of ships and docks, and it offers better waterproofing and stability than B-B grade. It is more suitable for applications that require a uniform surface and waterproofing.

The difference between marine plywood and standard plywood

How to choose?

We are happy to advise you on the use of plywood and hope to be able to give you some valuable advice after learning about your use.

We recommend materials based on your waterproofing needs and strength. This helps you pick the right plywood. It saves you money and boosts efficiency. Composite Box’s mission is to grow with our customers. Composite Box’s mission is to “grow with our customers.”

Application of marine plywood

Composite Box’s marine plywood can be used for boats, interiors, timber frame construction, truck box bodies, cladding, canopies, exterior cladding, waterproof workbenches, tables, plantation.

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.