Rigid Polyurethane Foam: The Ultimate Guide

What is PU foam?

Polyurethane comes in two types: rigid and flexible foams. This is a rigid foam made from polyurethane chemistry. It is mainly used for heat insulation, warmth, waterproofing, sound insulation, and so on. It can be used in automobiles, ships, decoration, construction, and other fields. Polyurethane foam keeps its shape after curing. It offers strong compression resistance in some areas. In flexible foam, it works well for cushioning materials like mattresses and seats.

Flexible and rigid foams have different uses and are manufactured in different ways; in this article, you will have enough knowledge about them.

Difference between rigid and flexible polyurethane foam

Rigid and flexible foams range in density from high to low, rigid foams perform better in terms of insulation and also have a sturdy structure. Flexible foams are characterized by their softness. But they still have a lot in common, such as:

- Thermal insulation

- Waterproofing

- Soundproofing

Here are their respective characteristics; let’s go deeper together.

Insulation Flexible Polyurethane Foam Advantages

Flexible polyurethane is lighter than rigid polyurethane. It is soft and flexible. It also dampens vibrations. This material is typically used in casting, molding, or spraying processes, and it is easy to work with.

Insulation Rigid Polyurethane Foam Advantages

Rigid polyurethane foam is hard and heavy. It holds its shape for a long time. Its density is higher than that of flexible polyurethane foam. This difference comes from their formulas and how they are made. It can be used in places where structural support is needed.

It is not as flexible as flexible polyurethane, but it has better thermal insulation and lower thermal conductivity.

Polyurethane foam applications

Rigid foam and flexible foam have unique traits and properties. They serve different purposes. If you’re unsure which one to use in your industry, read the next section. It will help you, and you won’t need to search for more information.

Rigid Polyurethane Foam

Rigid polyurethane foam has a particularly wide range of uses, usually can be used in RV campers, insulated refrigerated trucks, construction houses, etc.; the main role is to keep warm and insulate, and it can also provide a certain degree of noise reduction (polyurethane’s main function is to insulate).

Applications in automobiles:

- Motorhome

- RV

- Camper trailer

- Refrigerated truck body

- Small reefer trailer

Applications in construction:

- Roofs and attics

- Walls

- Partitions

- Cold storage warehouses

Note: The role of polyurethane in the above can mainly provide thermal insulation, but it should be noted that the waterproof performance of PU foam is better than that of XPS foam. If you are looking for better waterproof performance, you can choose XPS foam as the use of rigid foam.

Flexible PU foam

Flexible insulating polyurethane foam is mainly used for applications that do not need to bear structure, and its softness with elastic advantages can be used in other areas.

- Automotive field:

Flooring, carpet backing, cabs, door panels, roofs, steering wheels, main driver’s seats, rear seats, passenger seats, etc. - Packaging:

flexible insulated boxes, insulated cups, insulated bags, and insulated blankets. - Other applications:

HVAC equipment, insulated pipes, etc.

Difference between polyurethane and (polystyrene) EPS board core

Polyurethane foam is actually much broader in performance and application than EPS. In terms of R-value, EPS has an R-value per inch of about 4, while PU can be up to 7, and PU has better insulating properties.

Polyurethane foam, whether rigid or flexible, is stronger than EPS, and flexible polyurethane foam is more adaptable to different complex shapes.

Polyurethane foam has good flame retardant and fire resistance properties; the maximum operating temperature can reach 80 °C.

A leading provider of polyurethane foam solutions.

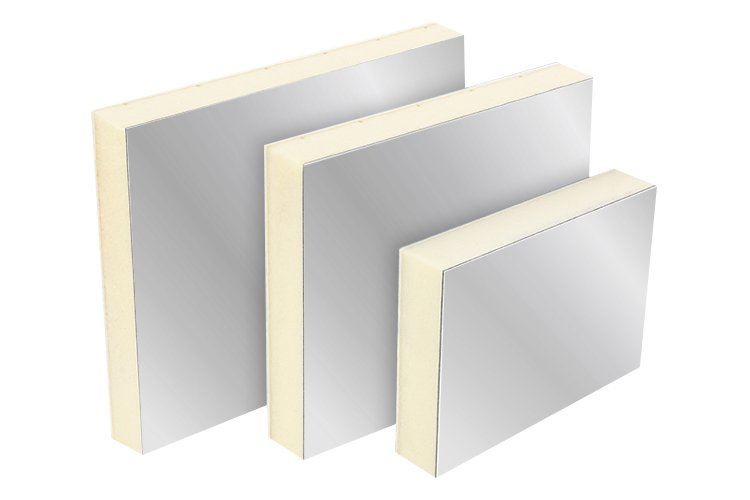

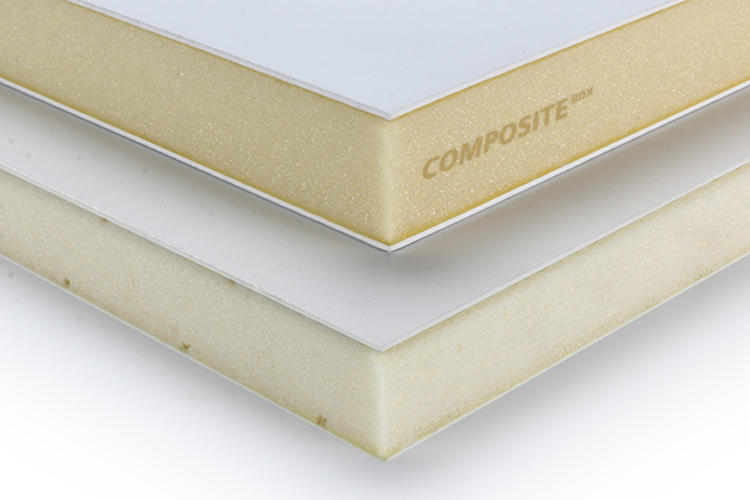

Composite Box is a leading polyurethane solutions provider; we offer polyurethane panels in a variety of skins, and we can produce house panels, caravan panels, truck panels, etc. We also offer a refrigerated truck body design service, and we deliver using CKD (Complete Knock Down) kits.

We specialize in the production of composite materials and their use in the automotive industry. In short, the use of polyurethane would not be possible without Composite Box’s years of research and invention.

Related Post

Related Product

Author introduction

Hello, customers

My name is Jack Yu and I am the Business Manager of Composite Box. I have been in the business of sandwich panels, refrigerated trucks and RVs for more than 10 years. Please feel free to contact us. I am happy to provide you with the best service and products.

Email: info@composite-box.com | Tel: 86+17280837525