refrigerated and freezer box truck body

Composite Box specializes in refrigerated CKD box truck body design and production. It can be used for cold storage and freezing. Provide 50mm+ fiberglass sandwich panels with PU and XPS foams. They must have the best thermal insulation and heat preservation, with a thermal conductivity close to 0. Support multi-temperature zones and kit options.

Refrigerated box truck bodies can cater to cargo such as frozen food, fresh vegetables and fruits, meat, eggs, and dairy products. Besides, we also offer refrigerated trailers, refrigerated semi-trailers, and dry box truck bodies.

We support CKD delivery and accept OEM and ODM custom work. Composite is a professional supplier of refrigerated trucks

Features

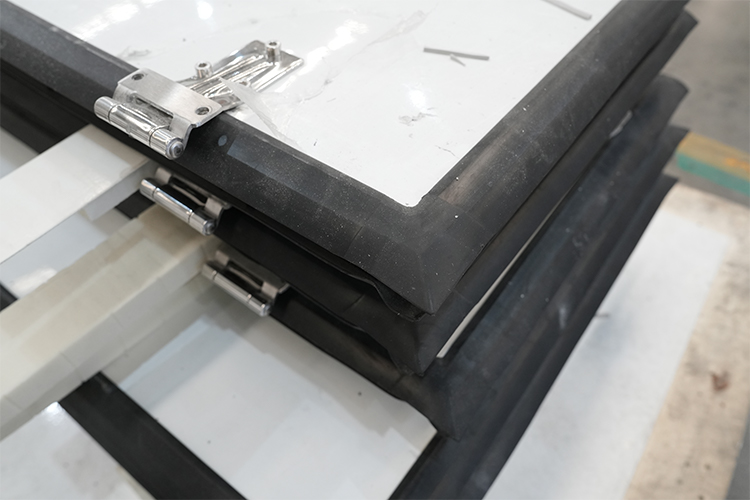

Specialised Foam Sandwich Panels for Reefer Trucks

We are also a professional foam sandwich panel manufacturer, we produce high quality insulated sandwich panels for refrigerated trucks.

It is made of one-piece composite panels with foam core made of PU and XPS, and the outer skin is made of FRP or GRP, and the thermal insulation property of PU is 0.022W/mK.

The other one is XPS, with an insulation performance of 0.029W/mK, which allows you to drive on hot roads without worrying about high temperatures.

It is also easy to install, no complicated tools are required, just a screw gun is needed to complete the installation smoothly.

Get Free Quote of refrigerated and freezer box truck body

product Catalog

contact us

Product advantages

Composite box early to provide foam sandwich panels for refrigerated trucks; after years of research and production, we can provide a complete solution, and in terms of performance, we can do better.

- Cost-effective: in-house production capacity reduces costs.

- Customised kits: up to 16 types of kits available, including floor, front door, locks, etc.

- High strength: using FRP as skin, vacuum high-temperature lamination.

- Long service life: not easy to age, good waterproof performance, long service life

- Easy installation: one person can install it.

- Advanced material: beyond the traditional aluminum truck body panels

Customisation options

Our kit has the following options available: wall panels, floors, cargo E-track, side door, edge and corner laps, door frame, lock and hinge, multi-temperature zone partition, subframe, refrigeration unit, rear bumper and side guardrails, and meat hanging rail system.

- Additional processing of accessories is available.

- Internal reinforcement: plywood, aluminum tube, and FRP tube can be used for box truck body reinforcement.

- CNC machining, cutting, grinding, etc. are available.

Customisation options

Product Parameter

| Parameter Name | Data Range |

|---|---|

| Product Name | Refrigerated box truck body |

| Structure | Fiberglass facing XPS PU foam sandwich panel |

| Length | 3 – 12 meters |

| Surface Thickness | 0.7mm – 5mm |

| Thickness | 20 – 150mm |

| Width | Max 3.2 meters |

FAQ

why choose us?

Customer Satisfaction

Insisting on high quality products and servers, centered around customer experience

Quality Assurance

We strictly control every production process to bring reliable quality assurance to our customers.

Advanced Production Line

The world’s top production line ensures product precision and efficiency.

Customization

We provide 100% customization, making orders less difficult.