CFRT plywood sandwich panels manufacturer in china

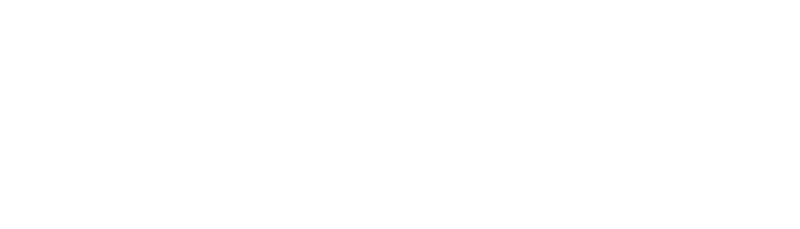

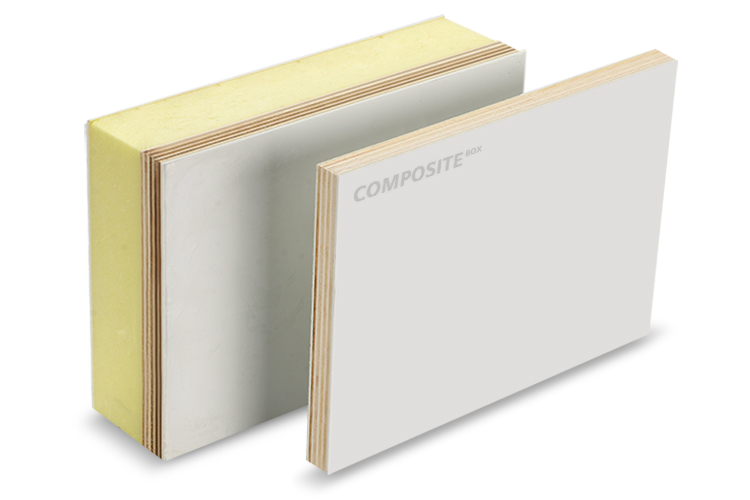

CFRT plywood sandwich panels are made of CFRT (Continuous Fibre Reinforced Thermoplastic – UD Tape) and plywood. They are laminated by high pressure vacuum using adhesive. These high-strength, corrosion-resistant composite panels are widely used where high strength and impact resistance are needed.

We are the top manufacturer of CFRT plywood panels. We offer OEM/ODM, 3D design, material selection, and other services.

제품 설명:

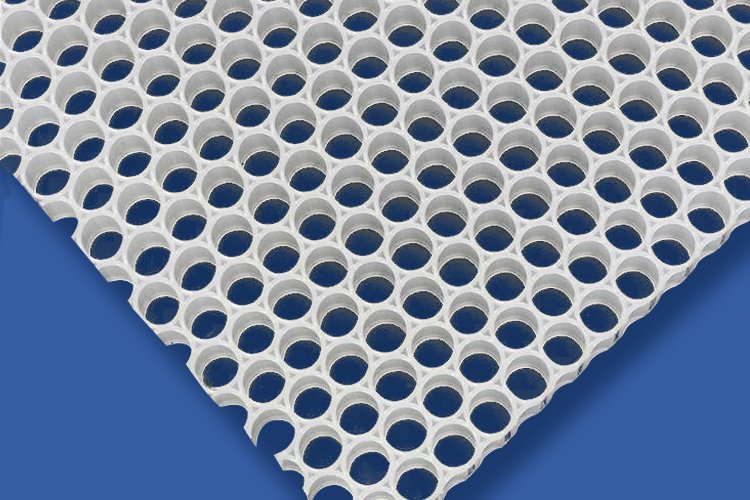

Composite Box is the best maker of CFRT sandwich panels. CFRT is made of multilayer UD tape. Plywood is made of laminated thin wood. Both are very strong and impact-resistant, as they are composite materials.

We can customize multiple layers of plywood. This will give it the right stiffness and strength. CFRT sandwich panels are a new, popular skinning material. They are strong yet lightweight and have the same features as CFRT.

기능:

- High-strength material, impact-resistant plywood is best suited for high-strength applications.

- CFRT skins are hard-wearing and less prone to cracking.

- CFRT is water- and moisture-resistant and prevents penetration of plywood.

- Flame retardant for added safety.

- Lower price than FRP, but is also more resilient.

- Easy CNC machining.

Structure of CFRT plywood sandwich panels

합판

plywood is multiple layers of thin wood slices laminated by adhesives, with layers of interlocking fiber structure to provide excellent stability and durability.

CFRT 시트

CFRT는 UD 테이프로 적층된 열가소성 FRP 시트입니다. 내후성, 내충격성, 복원력이 뛰어납니다.

컴포지트 박스

Application of CFRT plywood sandwich panels :

Dry van body

Wall panelling, flooring, ceilings for caravans.

Furniture manufacturing

캐러밴

Tables

Chairs

캐비닛

기술 매개변수

| 항목 | 매개변수 |

|---|---|

| 스킨 재질 | CFRT (Continuous Fiber Reinforced Thermoplastic), GRP (Glass Reinforced Plastic) |

| 핵심 재료 | Plywood (Poplar, Birch, Oak, Pine, Eucalyptus, Beech, etc.) |

| 두께 | 6.0 ~ 50mm |

| 너비 | Max 2.8m |

| 길이 | Max 12m |

| 표면 처리 | Glossy/Matt PET film |

| 힘 | High strength, impact-resistant, strong compressive ability |

| Water Resistance | Moisture and water-resistant, prevents moisture penetration into the core |

| 난연성 | Flame retardant, meets safety standards |

| 처리 방법 | Supports CNC machining, easy to customize |

| 무게 | Lightweight material, maintains high strength while reducing overall weight |

| 사용자 지정 옵션 | Size, surface treatment, embedded design, etc. |

왜 우리를 선택해야 할까요?

고객 만족

고객 경험을 중심으로 고품질의 제품과 서버를 고집합니다.

품질 보증

고객에게 신뢰할 수 있는 품질 보증을 제공하기 위해 모든 생산 공정을 엄격하게 관리합니다.

고급 생산 라인

세계 최고의 생산 라인은 제품의 정밀도와 효율성을 보장합니다.

사용자 지정

100% 커스터마이징을 제공하므로 주문이 더 쉬워집니다.