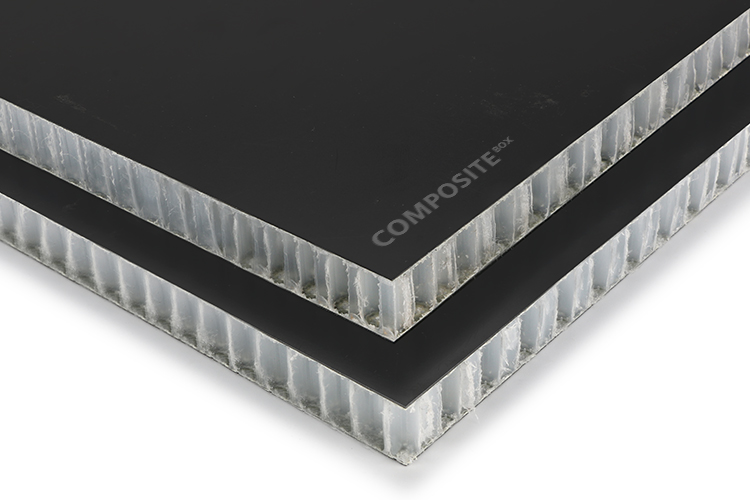

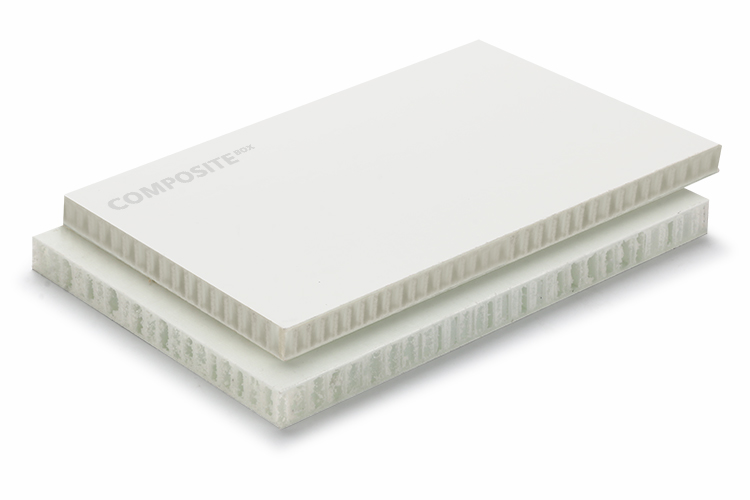

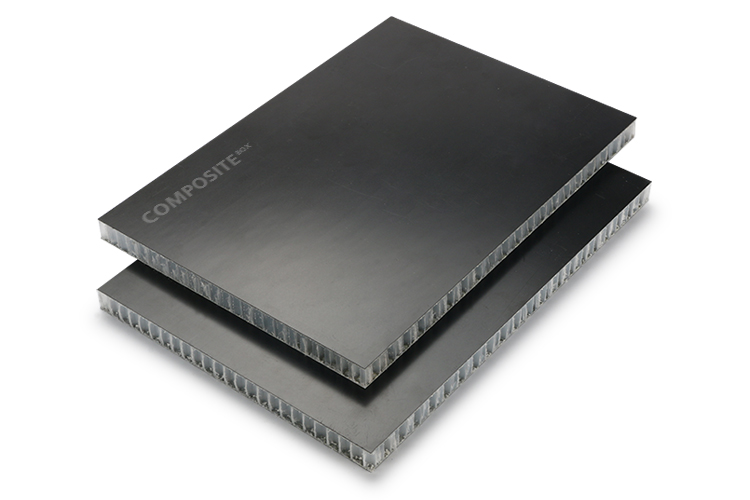

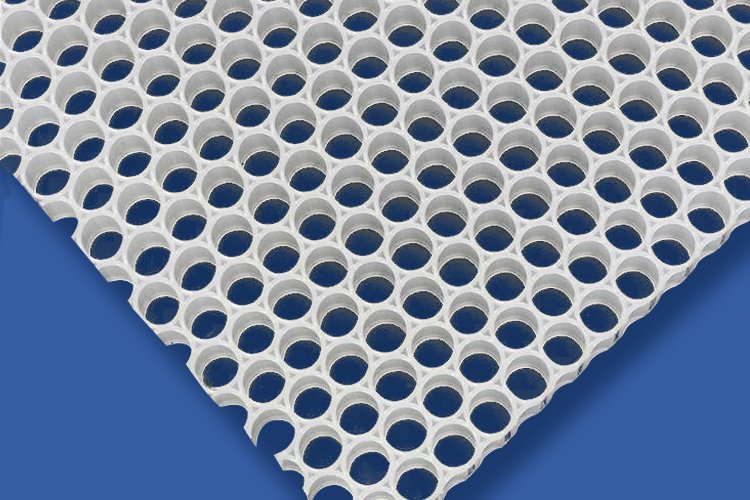

폴리프로필렌 허니콤 코어

PP honeycomb core is a thermoplastic material with a circular open-cell design. Its density ranges from 58 to 105 kg/m³. It is a plastic sheet material with excellent bending strength. Even though it’s very lightweight, it has great bending strength. This gives it a high strength-to-weight ratio. This plastic sheet material can be laminated with non-woven polyester fiber fabric. It features heat resistance, corrosion resistance, moisture resistance, and sound insulation properties.

기능:

제품 설명

PP honeycomb core is a plastic sheet with a circular open-cell design. It is used as the core material for sandwich panels, providing high strength. It’s often used in box truck bodies, RVs, construction, flooring, and marine applications. We offer maximum lengths of 3.2 meters, maximum widths of 1.6 meters, and thicknesses ranging from 5 mm to 200 mm.

Composite Box provides PP honeycomb cores with non-woven polyester fiber facings. These facings improve adhesion and stop adhesive from penetrating. PP honeycomb cores support thermal forming, vacuum infusion, and other processing methods. They are easy to process, ensuring efficient production. We offer a variety of facings for selection.

장점

PP honeycomb cores offer numerous advantages, many of which are unmatched by other core materials. Their strong performance comes from their design, how they are made, and the qualities of PP resin.

High Strength

PP honeycomb cores have great bending resistance. They absorb and spread out external forces, which help reduce impact damage. They can withstand significant impacts and bear heavy loads.

Material Efficiency

In the past, nearly all materials were solid. Under the same strength conditions, PP honeycomb cores use less material. They offer better lightweight performance under higher compressive strength.

Corrosion Resistance:

PP honeycomb cores have a long service life, thanks to their excellent corrosion resistance. They can withstand the corrosion of acids, alkalis, and salts in humid environments while maintaining structural stability. Therefore, they are suitable for applications in low-temperature, marine, and chemical environments.

Recyclability:

PP honeycomb cores are recyclable materials, as polypropylene has a 100% recyclable property. This significantly reduces resource consumption and carbon emissions. PP honeycomb cores are non-toxic and harmless during the recycling process, making them a popular recyclable material.

| Parameter Category | PP6 | PP8 | PP10 | PP12 | PP14 | PP16 | PP18 | 가치 |

|---|---|---|---|---|---|---|---|---|

| Cell Size (mm) | 6 | 8 | 10 | 12 | 14 | 16 | 18 | – |

| Density (kg/m³) | 87 | 82 | 77 | 72 | 71 | 83 | 85 | – |

| Compressive Strength (MPa) | 1.85 | 1.70 | 1.62 | 1.50 | 1.48 | 1.90 | 1.92 | – |

| Compression Modulus (MPa) | 52.0 | 46.5 | 42.0 | 39.5 | 39.0 | 51.0 | 51.5 | – |

| Shear Strength (MPa) | 0.70 | 0.52 | 0.47 | 0.42 | 0.41 | 0.57 | 0.58 | – |

| 최대 길이 | – | – | – | – | – | – | – | 3.2 m |

| 최대 너비 | – | – | – | – | – | – | – | 1.6 m |

| 두께 | – | – | – | – | – | – | – | 5mm~200mm |

컴포지트 박스

애플리케이션

PP honeycomb cores are suitable for a wide range of applications.

- RV panels, RV trailers

- Box trucks, moving trucks

- Construction, partition walls, and interior decoration materials

- Industrial railway applications, etc.

- Wind turbine nacelles, solar panel backsheets, etc.

왜 우리를 선택해야 할까요?

고객 만족

고객 경험을 중심으로 고품질의 제품과 서버를 고집합니다.

품질 보증

고객에게 신뢰할 수 있는 품질 보증을 제공하기 위해 모든 생산 공정을 엄격하게 관리합니다.

고급 생산 라인

세계 최고의 생산 라인은 제품의 정밀도와 효율성을 보장합니다.

사용자 지정

100% 커스터마이징을 제공하므로 주문이 더 쉬워집니다.