Foam Core Sandwich Panel Manufacturer in China

Foam Core Sandwich Panels Manufacturer

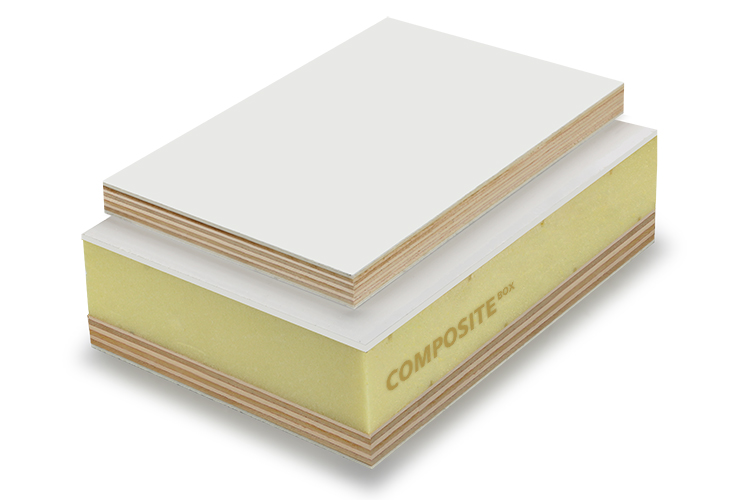

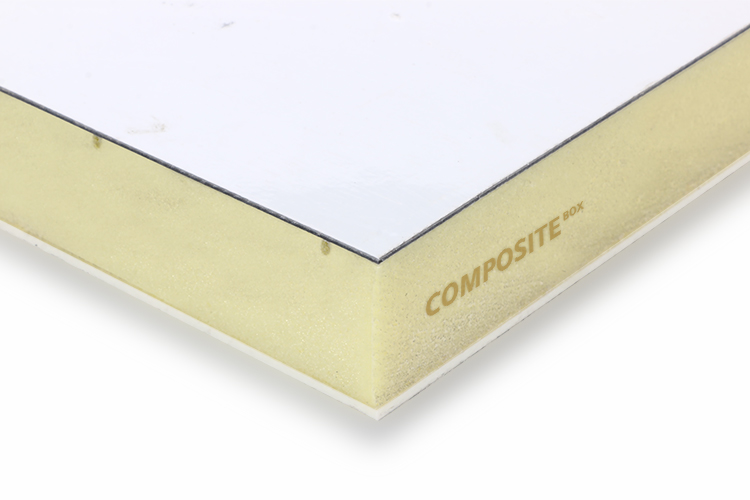

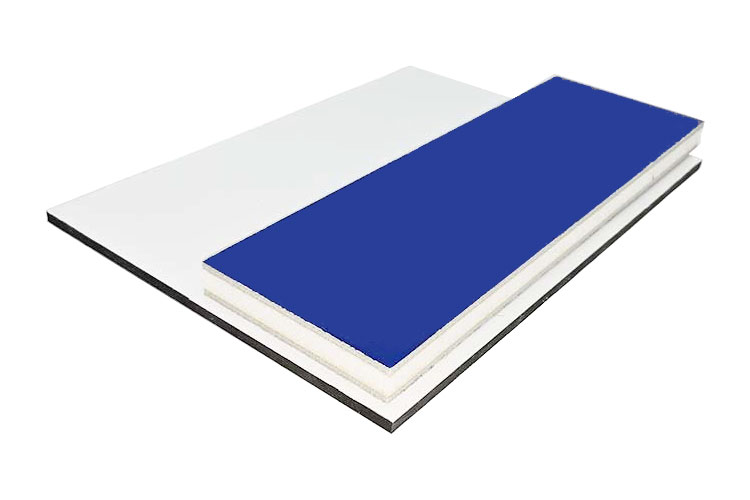

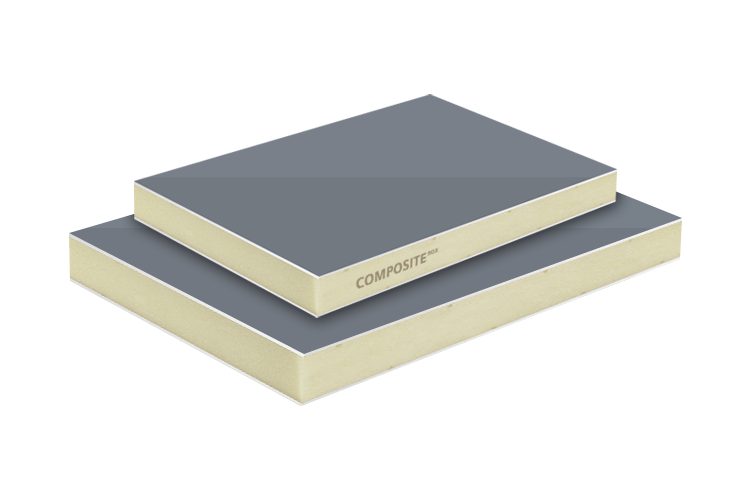

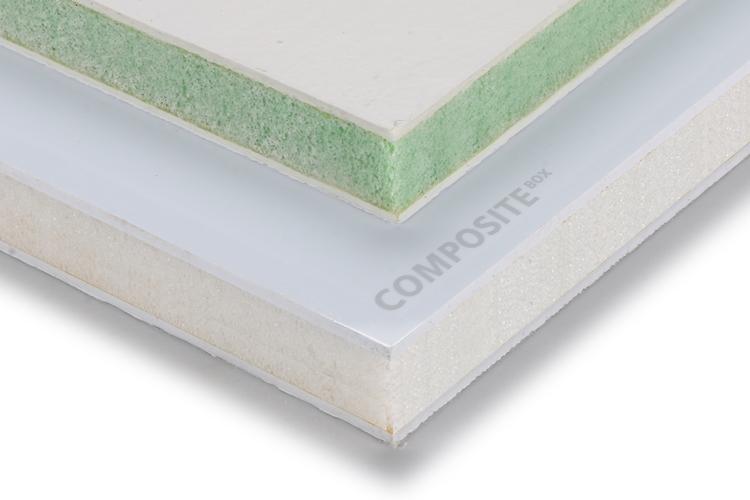

Foam core sandwich panels are popular composite panels. Foam core (XPS,Polyurethane,PET,PVC etc.). They can replace the traditional sandwich core. The skin can be laminated with fiberglass, 탄소, plywood, and so on. With lightweight, excellent stiffness, and high strength.

Foam sandwich panels are widely used. Commonly used in roof for RV, wall panels, marine sandwich panels, lightweight insulation panels, box truck bodies, RVs, furniture, transportation, engineering, and so on. We can help you choose the sandwich panels. We offer OEM/ODM production and give you the best experience.

- Structure customized production, thickness 6–100 mm.

- Support embedded reinforcement.

- CNC finishing, grinding, cutting, etc.

- ISO 9001, CE, and other certifications

장점:

- Lightweight: foam density 30 KG ~ 300 KG/m³.

- Strength-to-weight ratio: both fiberglass, carbon, and plywood foam sandwich panels are stronger than other traditional materials of the same weight.

- DIY structure: the structure of the sandwich panel can be customized according to the actual application and demand.

- Corrosion resistance: Foam sandwich panels, including those with 스테인리스 스틸 합판, are corrosion resistant and ideal for wet environments.

- Cost saving: Compared with the use of aluminum composite panels(ACP), steel panel. Foam sandwich panels have a lower cost.

- Fireproof: Flame retardant can be added to enhance safety performance.

- High strength: Both foam and skin have high strength.

- Insulation: Using XPS and PU foam can be used for refrigerated trucks, thermal insulation, and other applications.

- Water and Moisture Resistance: Some foams are rigid closed-cell structures where moisture cannot enter and air corrosion can be prevented, which ensures that the foam structure remains intact.

- Soundproofing can cut the sound of the ship, can reduce most of the noise pollution, suitable for housing, exterior walls, partitions, and other applications.

관련 제품:

XPS Sandwich Panels

특성: Extruded polystyrene (XPS) foam core, lightweight, high strength and excellent insulation properties for refrigerated trucks, roofs, walls and cold storage applications.

- Density: 32-45 kg/m³

- Thermal conductivity: 0.03 W/m-K

- Compressive strength: ≥200 kPa

Aluminum Foam Sandwich Panels

특성: Aluminum Foam Sandwich Panel, also known as ACP Foam Panel, has excellent impact resistance and is a high-strength exterior material used for ships, buildings, trailers.

- Aluminum skin thickness: 0.5~2mm

- Adhesive: Polyurethane adhesive

- Foam core: PU, XPS, PET, PVC, PP honeycomb

Stainless Steel/Galvanized Steel Foam Sandwich

특성: Stainless Steel/Galvanized Steel Foam Sandwich is perfect for high-strength needs. It works well for building facades and off-road caravans. This material is resistant to rust and strong against corrosion. You can use it in tough environments.

- Coating: PE, PVDF

- Thickness: 8–120 mm

- Skin: 202/304/316 austenitic stainless steel, galvanized steel sheets

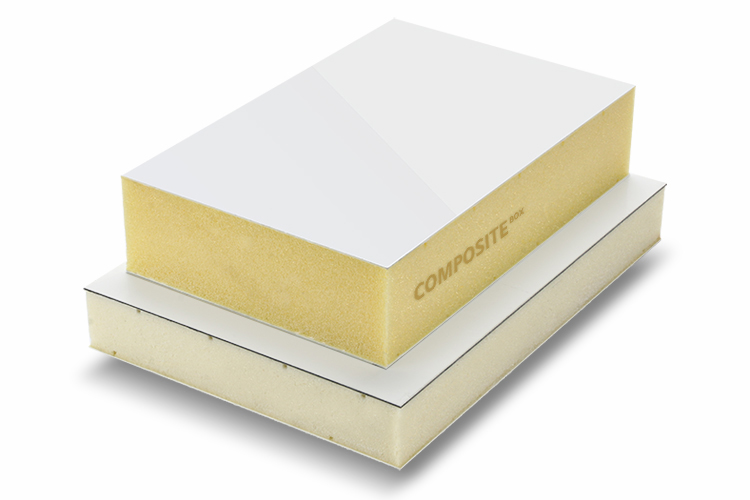

PU 샌드위치 패널

특성: Polyurethane (PU) foam core sandwich panels with thermal insulation and moisture resistance, widely used in refrigerated trucks, building insulation and industrial panels.

관련 제품:

- Density: 35-60 kg/m³

- Thermal conductivity: 0.022-0.026 W/m-K

- Compressive strength: ≥150 kPa

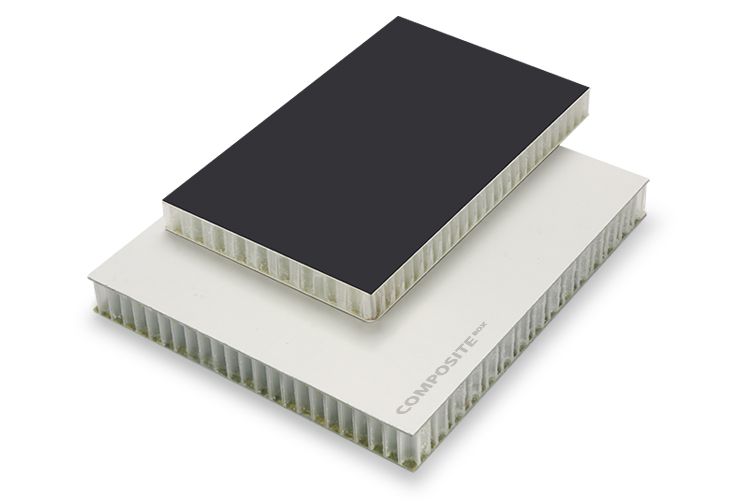

PET Sandwich Panels

특성: Environmentally friendly and durable polyethylene terephthalate (PET) foam core for lightweight structural applications such as marine and transportation equipment.

- Density: 60-300 kg/m³

- Thermal conductivity: 0.032-0.04 W/m-K

- Compressive strength: 0.7-2.5 MPa

PVC Sandwich Panels

특성: Polyvinyl Chloride (PVC) Foam Core Sandwich Panels are strong, easy to process and suitable for a wide range of applications in building decoration, advertising displays and light structures.

- Density: 50-80 kg/m³

- Thermal conductivity: 0.03-0.035 W/m-K

- Compressive strength: 1.5-3.0 MPa

PU 폼 보드

PU foam board is a rigid insulation foam core. It can be combined with other materials. It provides excellent insulation and thermal performance. It is flame-retardant and easy to process. It is suitable for use in refrigerated vehicles and building structures, etc.

- Density: 32–65 kg/m³

- Thermal conductivity: 0.022–0.028 W/m/K

- Compressive strength: 2.0–4.0 MPa

- Temperature range: -38°C to 118°C

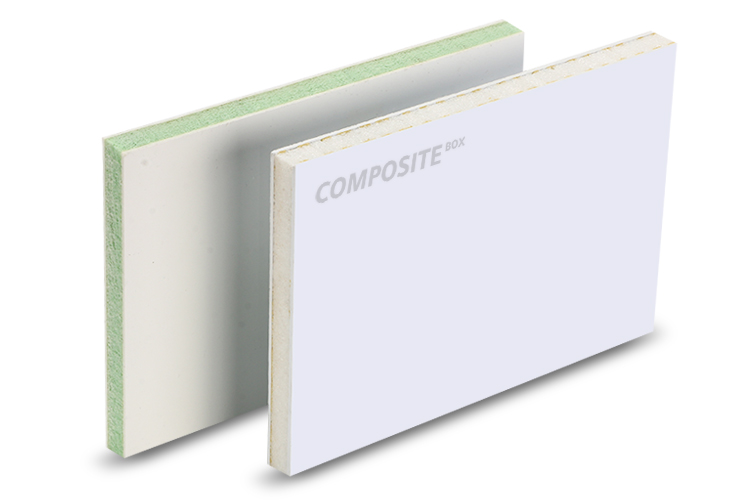

XPS 폼 보드

XPS foam board is a high-performance closed-cell rigid foam with excellent thermal insulation, waterproofing, and durability properties, reducing carbon emissions. It is suitable for building insulation, refrigerated transportation, and sandwich panels. Composite Box offers a variety of sizes and CNC machining customization.

- Excellent thermal insulation performance

- Superior waterproofing performance

- High durability and long service life

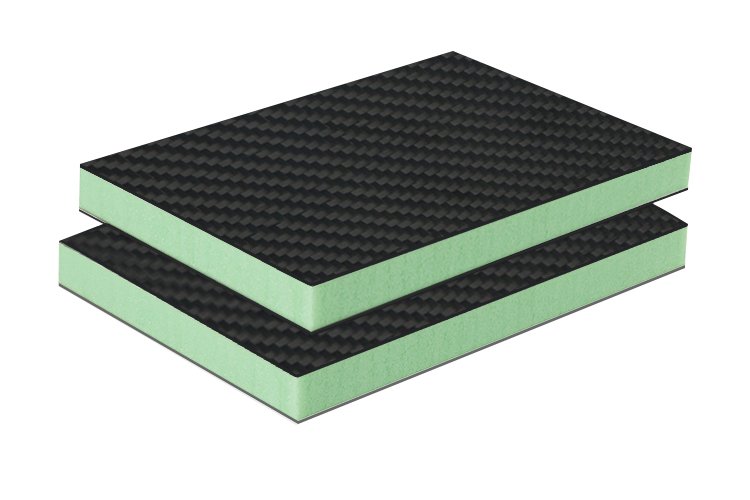

탄소 섬유 샌드위치 패널

Carbon fiber sandwich panel is made of foam core and carbon fiber reinforcement. With high strength, light weight, wear-resistant and other properties.Suitable for yachts, aerospace and other applications.

- 빛

- Smooth

- 내구성

- Temperature range: -38°C to 118°C

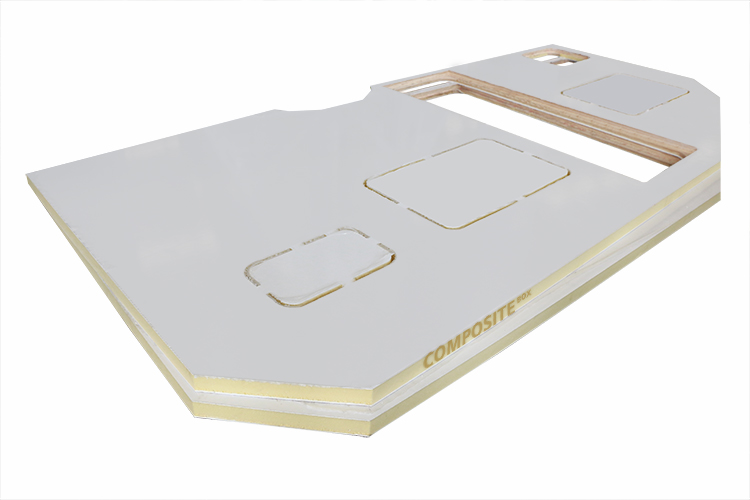

맞춤형 처리 서비스

- We provide customized service for processing of foam sandwich panel.

- CNC: Provide CNC mechanical cutting and chipping, the drill is HSS

- Vacuum laminating: using high pressure laminating technology, the surface is flat and compact

컴포지트 박스

Application of foam sandwich panels :

Van, RV:

- It can be used for manufacturing insulated box truck panels for 냉장 트럭 차체 and refrigerated trailer bodies.

- Dry vans, high-bay trucks, etc.

- Camping vehicles, rigid tents, mobile vending vehicles, RVs, etc.

건설 산업:

- Exterior wall panels, roof panels, partition panels, insulation panels, gates, etc.

Transportation:

- Plywood for ships and yachts, as well as internal structures.

- Lightweight car body materials

가구:

- Can be used for fire doors, security doors, soundproof doors, fences, and other applications.

왜 우리를 선택해야 할까요?

고객 만족

고객 경험을 중심으로 고품질의 제품과 서버를 고집합니다.

품질 보증

고객에게 신뢰할 수 있는 품질 보증을 제공하기 위해 모든 생산 공정을 엄격하게 관리합니다.

고급 생산 라인

세계 최고의 생산 라인은 제품의 정밀도와 효율성을 보장합니다.

사용자 지정

100% 커스터마이징을 제공하므로 주문이 더 쉬워집니다.