FRP 패널 절단 방법

Introduction to Fiberglass Reinforced Panels

Fiberglass reinforced panels are high-performance composite materials, this post is about how to cut it, let me start with an introduction to it, which is made of a composite of glass fibers and resin matrix, comparing with the traditional wood and aluminum alloy, it is corrosion-resistant and waterproof. moisture resistant advantages.

FRP panels can work in any environment. On a daily basis, FRP panels can be found everywhere. It can be used in construction, box truck bodies, waterproofing applications and caravans. It reduces weight, improves fuel efficiency, strong durability and aesthetic properties, and also keeps things tidy.FRP is widely popular.

However, cutting FRP is much more difficult than cutting wood, as it has a complex internal structure and is much harder, leading to scrap, which adds to the cost. The cutting process also generates a lot of dust, which can pollute the environment and irritate the human respiratory tract. We need to choose the right tool, use the right way, and do a good job of safety protection. The above is the main content of this article.

CNC Cutting

CNC cutting is fully automated cutting, which is very different from circular saws and hand saws. CNC cutting is suitable for complex needs with high precision, CNC requires computerized programming, it uses diamond drills and has excellent fixation properties, which provide very precise cutting performance and smooth edges. We recommend CNC cutting because cutting by hand is dangerous and requires a lot of attention.

Tools Needed for Cutting FRP Panels

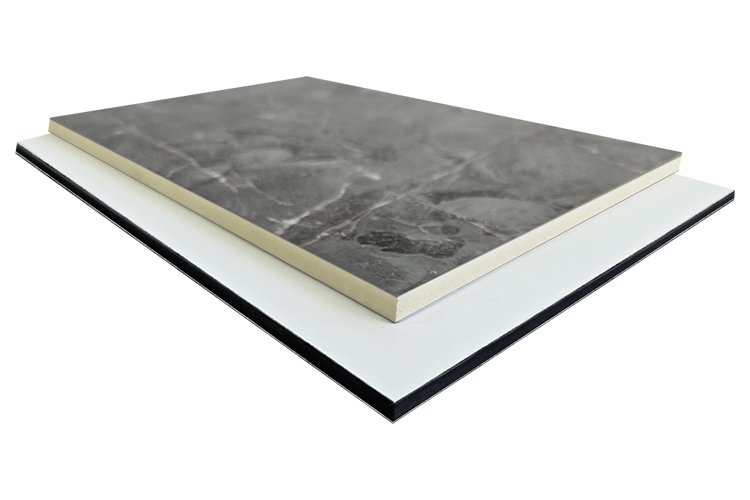

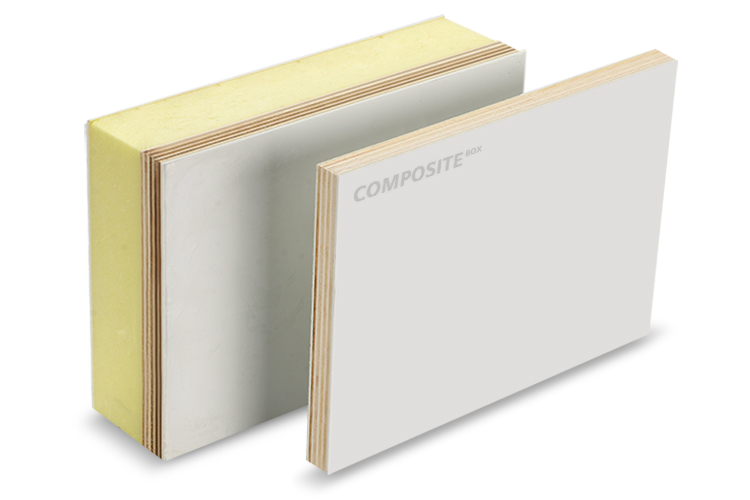

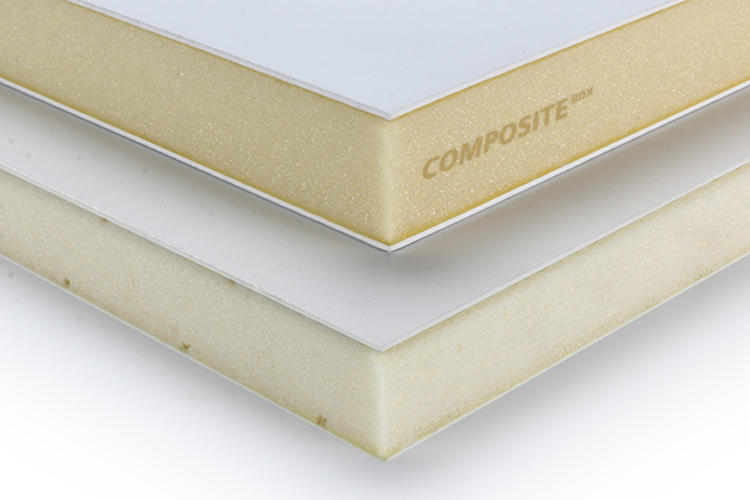

Composite Box has 20 years of experience in cutting FRP panels, we often cut FRP foam panels, FRP plywood panels and FRP honeycomb panels. When cutting FRP panels, you need some cutting tools and auxiliary tools, here is the list for you:

Commonly used cutting tools:

1. Circular Saw: Circular saw is suitable for straight line cutting, when cutting FRP, it can be cut directly and quickly, it is suitable for cutting into regular long strips, we recommend using 48 tooth blade.

2. Angle Grinder: It can cut into curves, it can be abraded to remove the excess, and it can be made into different shapes.

3. Hand saw: suitable for fine cutting, easy to grasp the strength, not easy to damage the panel, but the cutting speed is relatively slow.

4. Scissors: can quickly trim the edge, very convenient.

5. Chainsaw: when dealing with large areas, the use of electric saws is a good choice for large-scale industrial production scenarios.

6. Table saw: suitable for large linear cutting, with fine-toothed blade for the best results.

7. saber saw: suitable for FRP panel curve or irregular cutting

| Tool Name | Applicable Cutting Type | Importance Level | Recommendation Level |

|---|---|---|---|

| Circular Saw | Straight Line Cutting | 높음 | ★★★★ |

| Angle Grinder | Curve Cutting | Medium | ★★★ |

| Hand Saw | Fine Cutting | Medium | ★★★ |

| Scissors | Edge Trimming | 낮음 | ★★ |

| Chainsaw | Large Area Cutting | High (for large – scale industrial use) | ★★★★ |

| Table Saw | Large Straight Line Cutting | High (for large projects) | ★★★★ |

| Saber Saw | Curve or Irregular Cutting of FRP Panels | Medium | ★★★ |

Auxiliary tools

1. ruler: size is an indispensable tool for measuring data.

2. Marker: Used for marking and drawing lines.

3. Clamps: called fixing clamps, also called G-clamps, can make FRP panels fixed.

4. sandpaper: sandpaper with 60 mesh to 2000 mesh sandpaper, generally used from small to large, to ensure that the effect is smooth. High performance sandpaper such as 3M cubitron series 그리고 Norton are recommended. Recommended 120 ~ 320 mesh.

5. Sanding machine: Deep sanding of rough places can make the FRP cutting surface smoother.

How to cut FRP panels

Cutting FRP panels requires 3 steps, which are: pre-cutting preparation, choosing the right cutting technique and operation, and finishing and cleaning up, each of which is important and is an operation full of danger.

Preparation:

Accurate Measurement and Marking: Use a ruler to measure carefully along the edge of the FRP panel according to the planned dimensions, and then use a marker pen to draw a straight cutting line along the ruler, which is the key to cutting accuracy.

Stabilize the panel: Use jigs to fix the FRP panel, or use heavy weights to prevent it from shifting while working.

Wear protection: FRP dust is irritating and strong, it will bring some effects to the body, please wear protective gloves, masks and other protective tools.

Choose the right cutting technique

Straight cutting: Circular saw is the first choice, slow down the speed before cutting, hold it steady with both hands and push it along the cutting line at a constant speed to prevent overheating or skewing.

Curve or small pieces: angle grinder or hand saw on the battlefield, operation according to the curve trajectory precision force, hand saw can also be flexible to adjust the angle to ensure smooth cutting.

Thin plate cutting: thin plate with heavy-duty scissors, put a steady grip with both hands, find the right position to cut decisively, and quickly trim the edges.

Cutting

Cutting from the back: Lowering the knife from the back of the panel mitigates the risk of front shattering and provides a “good start” for subsequent cutting.

Maintain a stable speed: Cutting the whole process of even speed advancement, so that the blade uniform force, to avoid excessive force resulting in uneven cuts.

Check the blades: Look at the blades before cutting. Dull blades tend to cause rough edges, so replace them when you find a problem.

Finishing and Cleaning

Sanding Edges: Use sandpaper to sand along the cutting edges to remove burrs and smooth the edges. Follow the grit order from smallest to largest.

Dusting: Sweep with a broom, then deep clean with a vacuum cleaner, and finally wipe with a damp cloth to remove dust thoroughly.

Check the effect: check the panel against the requirements, and remedy any problems in time to ensure that the finished product is up to standard.

Safety Tips for Cutting FRP Panels

When cutting FRP panels, the most important thing is that you need to pay attention to safety and need to pay attention to the whole process. Prevent fingers from being cut, prevent inhalation of irritating dust, respiratory and eye protection is required, operations need to be carried out in a ventilated room, and it is best to avoid direct skin contact with the FRP material to reduce the risk of allergies and irritation. If contacted, or irritated by the material. Please follow the proper method to deal with it in time. The above content is a key point, please read it several times.

| Precautions | 세부 정보 |

|---|---|

| Prevent Cutting Injuries | Pay attention throughout the cutting process to prevent fingers from being cut by cutting tools. |

| Dust Protection | Avoid inhaling irritating dust, operate in a ventilated room, and wear respiratory and eye protection equipment. |

| Skin Protection | Try to avoid direct contact with FRP materials to reduce the risk of allergies and irritation. If contact occurs, handle it in a proper way in time. |

Common Mistakes to Avoid When Cutting FRP

Many people tend to use empiricism when cutting FRP, which is prone to problems. Here are a few things to keep in mind that will reduce most of the problems.

- 1. Need to choose the right tool, if you choose the wrong tool, it will cause the material to be scrapped.

- 2. The panel needs to be fixed, otherwise it will cause offset, resulting in the whole piece of material can not be used properly.

- 3. Safety protection cannot be perfunctory. Because FRP can hurt the human body, it will also cause health hazards.

- 4. Need to control the cutting speed. Prevent the blade from being damaged too quickly. It also increases the risk.

Best Tools and Blades for Cutting FRP Panels

When cutting FRP panels, you can use Festool circular saw, this circular saw is still good to use, the performance is more stable, we Composite Box use it for more than 10 years. You can ask our engineers where to buy them, or they are available locally.

For angle grinders we recommend the Festool AG 125-14 D. The Festool has a power of up to 1400W and an adjustable speed for users with delicate work.