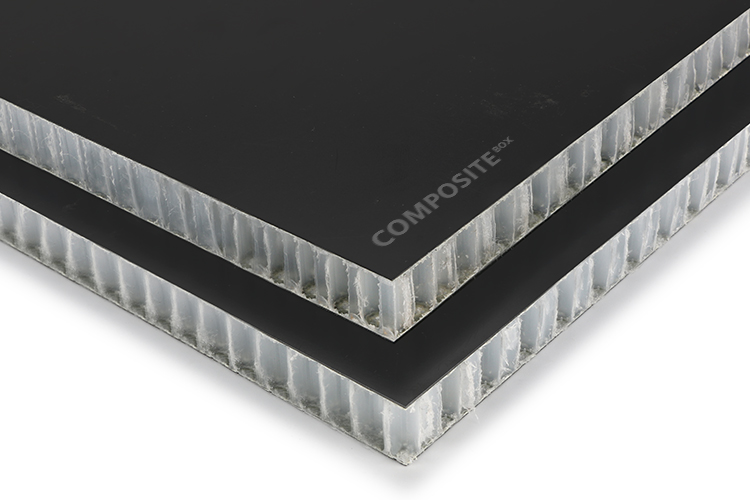

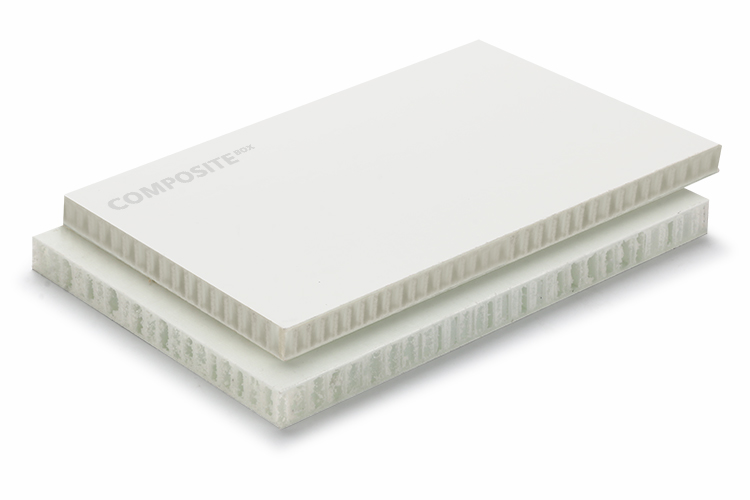

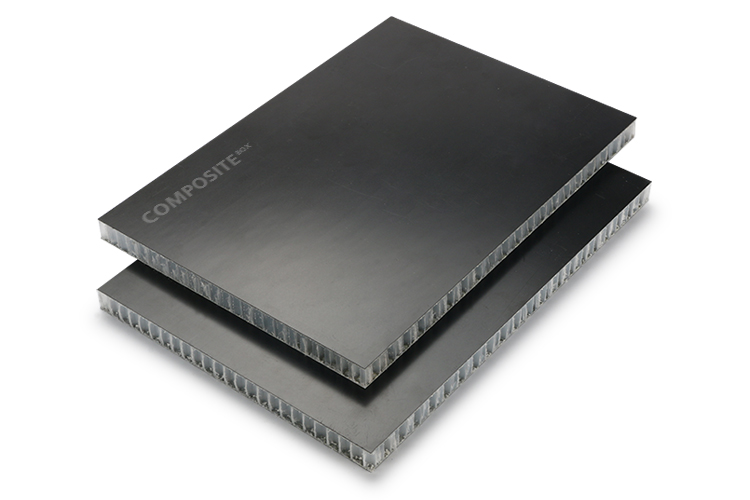

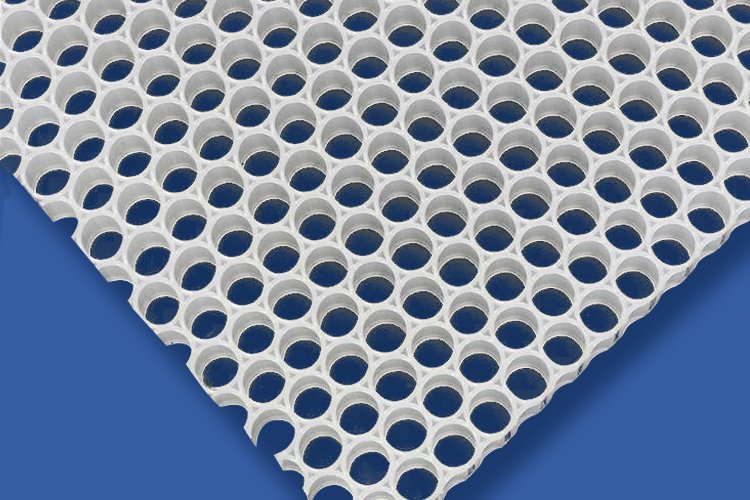

ポリプロピレン製ハニカムコア

PP honeycomb core is a thermoplastic material with a circular open-cell design. Its density ranges from 58 to 105 kg/m³. It is a plastic sheet material with excellent bending strength. Even though it’s very lightweight, it has great bending strength. This gives it a high strength-to-weight ratio. This plastic sheet material can be laminated with non-woven polyester fiber fabric. It features heat resistance, corrosion resistance, moisture resistance, and sound insulation properties.

特徴

商品説明

PP honeycomb core is a plastic sheet with a circular open-cell design. It is used as the core material for sandwich panels, providing high strength. It’s often used in box truck bodies, RVs, construction, flooring, and marine applications. We offer maximum lengths of 3.2 meters, maximum widths of 1.6 meters, and thicknesses ranging from 5 mm to 200 mm.

Composite Box provides PP honeycomb cores with non-woven polyester fiber facings. These facings improve adhesion and stop adhesive from penetrating. PP honeycomb cores support thermal forming, vacuum infusion, and other processing methods. They are easy to process, ensuring efficient production. We offer a variety of facings for selection.

メリット

PP honeycomb cores offer numerous advantages, many of which are unmatched by other core materials. Their strong performance comes from their design, how they are made, and the qualities of PP resin.

High Strength

PP honeycomb cores have great bending resistance. They absorb and spread out external forces, which help reduce impact damage. They can withstand significant impacts and bear heavy loads.

Material Efficiency

In the past, nearly all materials were solid. Under the same strength conditions, PP honeycomb cores use less material. They offer better lightweight performance under higher compressive strength.

Corrosion Resistance:

PP honeycomb cores have a long service life, thanks to their excellent corrosion resistance. They can withstand the corrosion of acids, alkalis, and salts in humid environments while maintaining structural stability. Therefore, they are suitable for applications in low-temperature, marine, and chemical environments.

Recyclability:

PP honeycomb cores are recyclable materials, as polypropylene has a 100% recyclable property. This significantly reduces resource consumption and carbon emissions. PP honeycomb cores are non-toxic and harmless during the recycling process, making them a popular recyclable material.

| Parameter Category | PP6 | PP8 | PP10 | PP12 | PP14 | PP16 | PP18 | 価値 |

|---|---|---|---|---|---|---|---|---|

| Cell Size (mm) | 6 | 8 | 10 | 12 | 14 | 16 | 18 | – |

| Density (kg/m³) | 87 | 82 | 77 | 72 | 71 | 83 | 85 | – |

| 圧縮強度 (MPa) | 1.85 | 1.70 | 1.62 | 1.50 | 1.48 | 1.90 | 1.92 | – |

| Compression Modulus (MPa) | 52.0 | 46.5 | 42.0 | 39.5 | 39.0 | 51.0 | 51.5 | – |

| Shear Strength (MPa) | 0.70 | 0.52 | 0.47 | 0.42 | 0.41 | 0.57 | 0.58 | – |

| 最大長 | – | – | – | – | – | – | – | 3.2 m |

| 最大幅 | – | – | – | – | – | – | – | 1.6 m |

| 厚さ | – | – | – | – | – | – | – | 5mm~200mm |

コンポジット・ボックス

アプリケーション

PP honeycomb cores are suitable for a wide range of applications.

- RV panels, RV trailers

- Box trucks, moving trucks

- Construction, partition walls, and interior decoration materials

- Industrial railway applications, etc.

- Wind turbine nacelles, solar panel backsheets, etc.

当社を選ぶ理由

顧客満足度

顧客体験を中心とした高品質の製品とサーバーにこだわる

品質保証

私達は私達の顧客に信頼できる品質保証をもたらすためにあらゆる生産過程を厳しく制御します。

高度な生産ライン

世界トップレベルの生産ラインは、製品の精度と効率を保証する。

カスタマイズ

我々は100%のカスタマイズを提供し、注文の難易度を下げます。