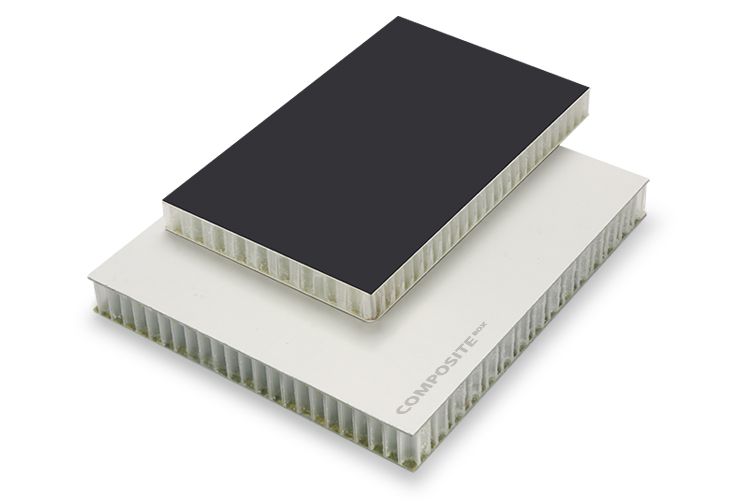

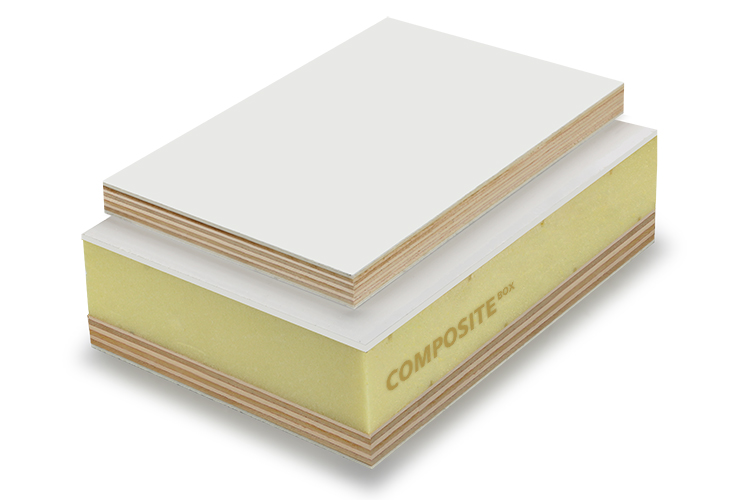

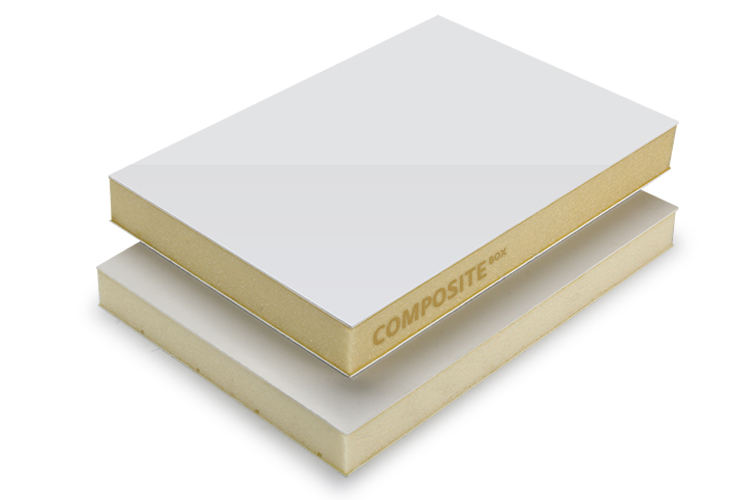

Hartschaumplatte

Composite Box bietet hochwertige Hartschaumplatten an. Zum Beispiel XPS-, Polyurethan-, PET- und PVC-Schaum. Sie können für LKW-Aufbauten, das Bauwesen und Wohnmobile verwendet werden. Sie werden für strukturelle, thermische Isolierung und Abdichtungsanwendungen verwendet.

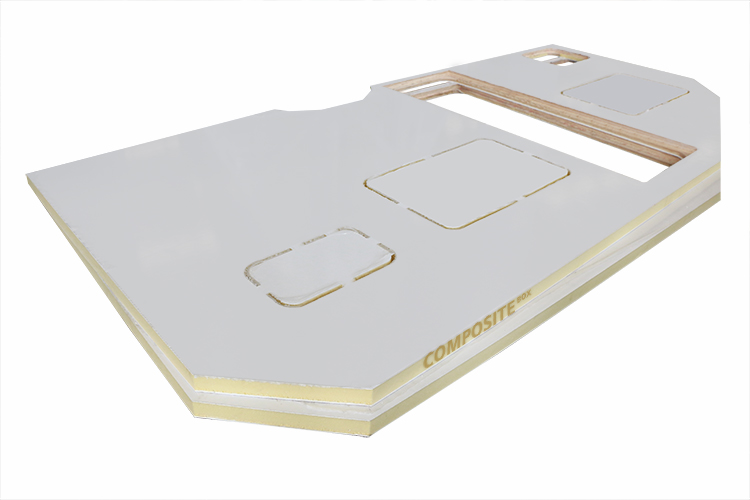

Wir bieten kundenspezifische Verarbeitungen in verschiedenen Größen und Dichten und damit eine Lösung aus einer Hand. Für Anfragen wenden Sie sich bitte an unseren Verkaufsleiter.

Merkmale:

- Dickenbereich: 5 mm bis 300 mm

- Dämmleistung mit R-Werten von 4 bis 22

- Hochfeste Strukturfüllung

- Dichte: 300-800 kg/m³

Produkt

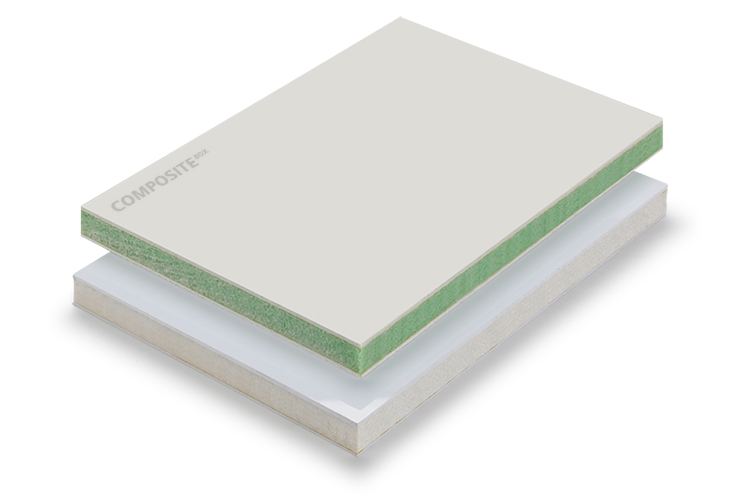

XPS-Schaumstoffplatte

Beschreibung:

Die XPS-Schaumplatte ist ein geschlossenzelliger Hartschaum mit hervorragenden wasserdichten Eigenschaften. Er basiert auf einer extrudierten Polystyrolstruktur. Sie hat gute Wärmedämmeigenschaften und eine extrem niedrige Wasseraufnahme, wodurch sie sich für eine Vielzahl von Anwendungen eignet.

- Der Gehalt an geschlossenen Zellen übersteigt 99%.

- Wärmeleitfähigkeit: 0,027 W/mK

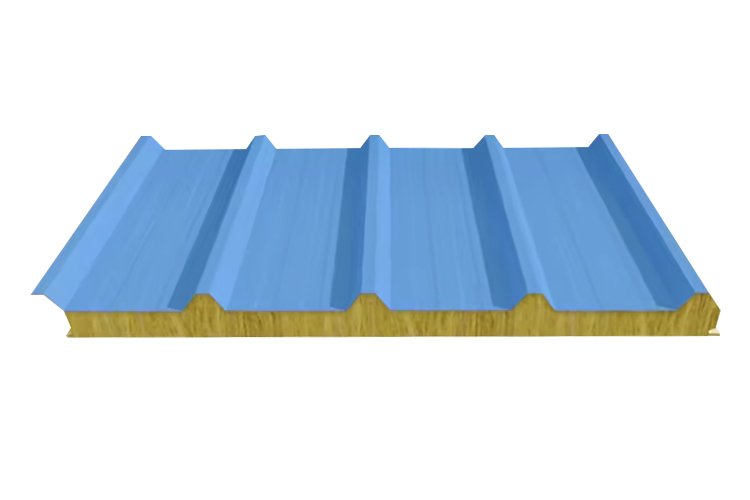

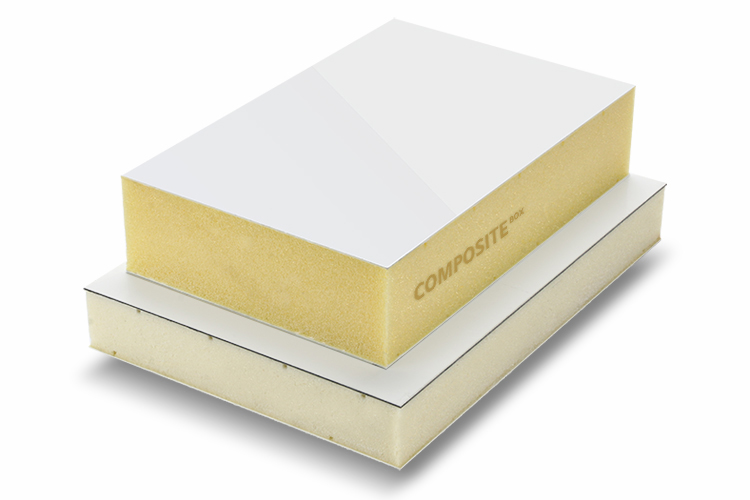

PU-Isolierschaumplatte

Beschreibung:

Polyurethan(PU)-Schaumplatten bieten außergewöhnliche Wärmedämmeigenschaften. Sie zeichnen sich außerdem durch eine ausgezeichnete Flammfestigkeit und Hitzebeständigkeit aus. Diese Platten sind ideal für Anwendungen wie Kühlfahrzeuge und isolierte Gebäude.

- Wärmeleitfähigkeit: 0,023 W/m-K

- Strapazierfähig und langlebig

PET-Schaumkernmaterial

Beschreibung:

PET-Hartschaumplatten werden aus Polyethylenterephthalat (PET) hergestellt. Es handelt sich um recycelbare Schaumstoffe. Diese Platten sind hitzebeständig und haben hervorragende mechanische Eigenschaften, was sie zu einer hervorragenden Wahl für Schaumstoffplattenanwendungen macht.

- Wasseraufnahmegeschwindigkeit: ≤2%

- Dichte: 40-300 kg/m³

- Druckfestigkeit: 1,5-2,5 MPa

PMI-Schaumstoffkernmaterial

Beschreibung:

Composite Box ist ein professioneller Hersteller von hochleistungsfähigen PMI-Schaumkern- und Sandwichplatten für die Luft- und Raumfahrt, die Schifffahrt, das Transportwesen und Windenergieanwendungen.

- Verhältnis Stärke/Gewicht: 30-50% höher

- Hitzebeständigkeit: >180°C

- Dichtebereich: 30-300kg/m³

Dauerhaftigkeit

Lange Lebensdauer

Robustheit

Kostenloses Angebot für Hartschaumplatten anfordern

Warum sollten Sie uns wählen?

Kundenzufriedenheit

Bestehen auf qualitativ hochwertigen Produkten und Servern, die das Kundenerlebnis in den Mittelpunkt stellen

Qualitätssicherung

Wir kontrollieren jeden Produktionsprozess streng, um unseren Kunden eine zuverlässige Qualitätsgarantie zu bieten.

Fortschrittliche Produktionslinie

Die weltweit führende Produktionslinie gewährleistet Präzision und Effizienz der Produkte.

Personalisierung

Wir bieten eine 100%-Anpassung an, die Bestellungen weniger schwierig macht.